www.balluff.com 17english

5

Configuration and parameterization (continued)

5.4 Setting the number of magnets

BTL7-V50D-… can evaluate up to 16magnets depending

on the length. In normal mode, it is recommended to set a

fixed number of magnets, as this reduces susceptibility to

malfunctions, and increases the processing speed. In

flexible magnet mode (FMM), the number of magnets is

variable.

For magnets that are not detected or parameterized, the

error value 0x7FFFFFFF is output as position and speed.

If more magnets than parameterized are located in the

measuring range (with FMM, more than 16), the excess

magnets are ignored. BTL7-V50D-… always evaluates the

magnets from the plug side regardless of other settings.

The number of magnets can be set in the Config Assembly

in the Number_of_Magnets entry if Config_Assembly_

Parameter_Recognition is set to 1. Otherwise the value set

in object100, Attribute6: Number of magnets (Number of

Magnets), is valid. The sensor is set to one magnet as

factory default. If the number of magnets is set to 0, the

sensor is in the Flexible Magnet Mode (see also

chapter5.2 Attributes of the device configuration

object on page13 and chapter 5.3 Parameterization

using the Config-Assembly on page16).

Flexible Magnet Mode (FMM)

In flexible magnet mode, the number of magnets is not

specified. The BTL7-V50D-... accepts any number of

magnets up to a maximum of 16 and even changes to the

number during operation. However, after changing the

number, this is signalized by the output of error value

0x7FFFFFFF on all magnets. This error value is taken back

after a configurable time in the parameter FMM Timeout.

The new number of magnets is accepted once this period

has elapsed. If no magnet is located in the detection

range, the error persists until at least one magnet is

detected. For magnets that are not present, the error value

0x7FFFFFFF is output as position and speed value.

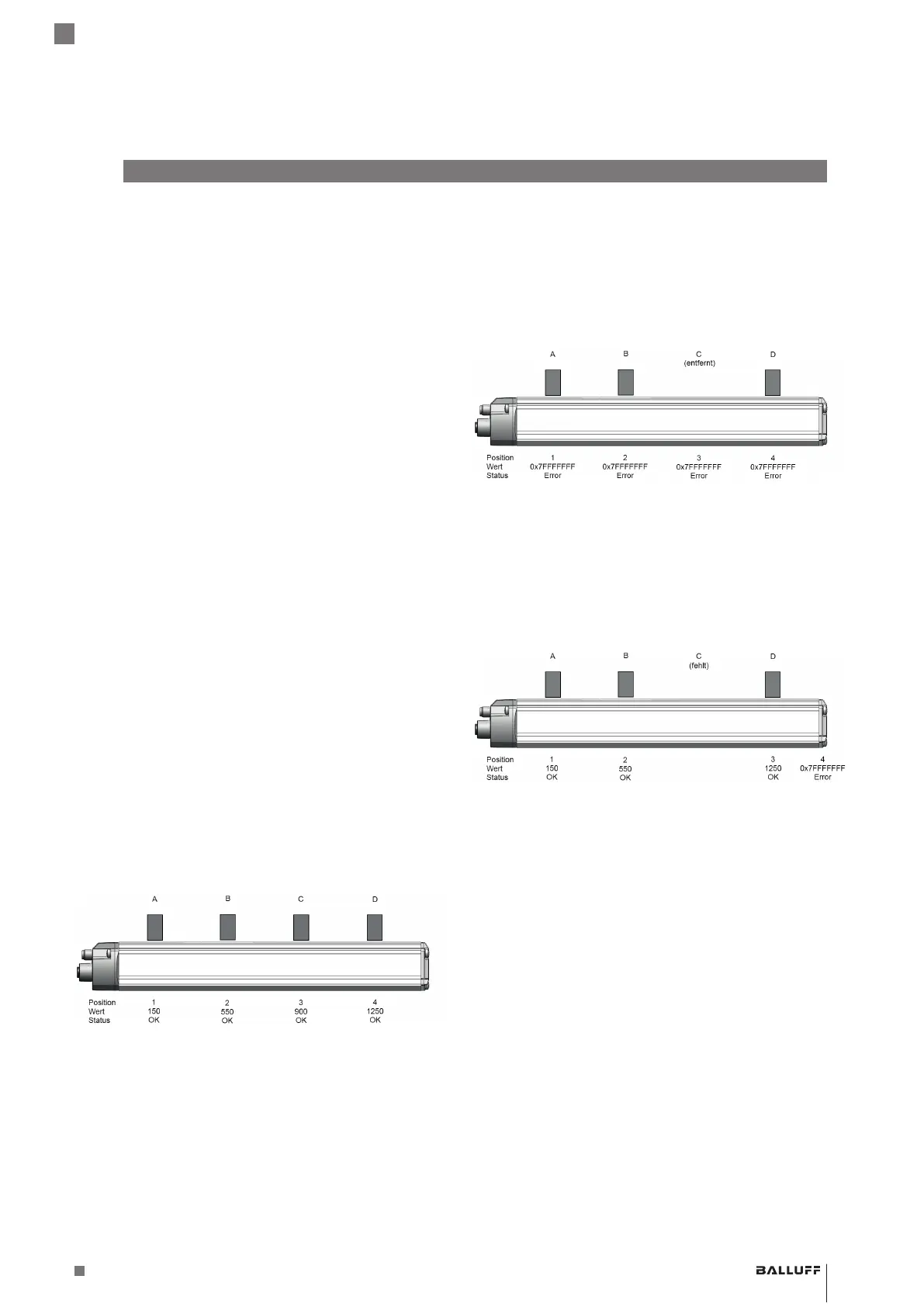

Fig. 5-2: Example with 4 magnets (exemplary style)

If, for example, you have four magnets (A, B, C, and D as

seen from the connector end), then magnet A is assigned

to position (or module) 1, magnet B to position 2, etc.

If magnetC is removed, an error value is output for all

positions for the time set in the Diagnostic time for FMM

parameter.

Fig. 5-3: Example: Magnet C removed (exemplary style)

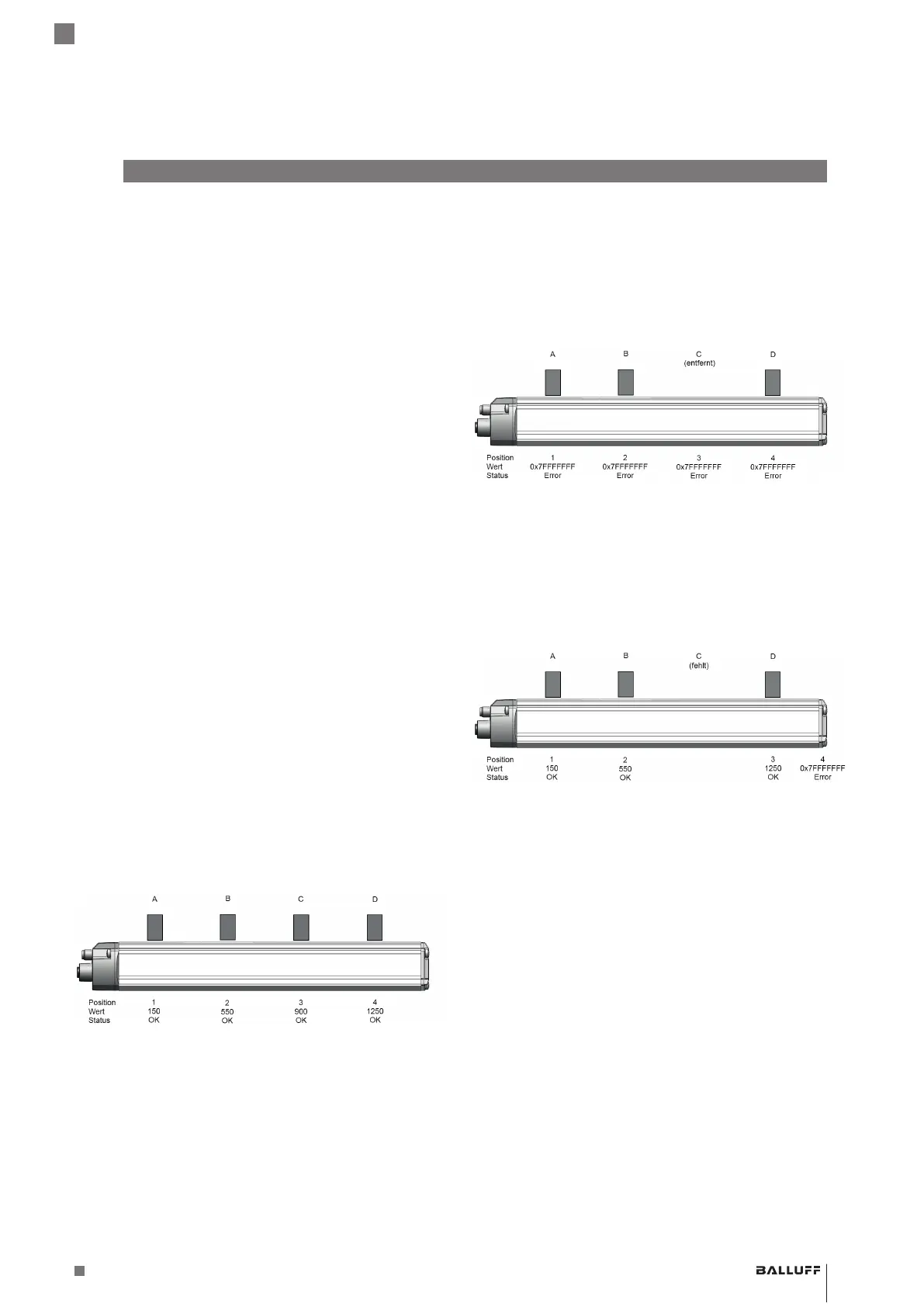

After the set time has elapsed, the magnets are again

assigned in the order in which they are detected. In our

example only three magnets are still detected. These are

assigned to positions 1-3. The missing fourth magnet is

assigned to position 4, which remains on the error value.

Fig. 5-4: Example: Magnet reassignment (exemplary style)

Please note that the evaluation of the positions in the

controller must be adapted to this arrangement.

The parameter FMM Timeout is configured in the Config-

Assembly (if Config_Assembly_Parameter_Recognition is

set to 1, see chapter5.3.4 on page16) or in the device

configuration object (seeAttribute16: FMM timeout on

page15).

BTL7-V50D-…

Configuration Manual

Loading...

Loading...