Bandit

48

Copyright 12/17

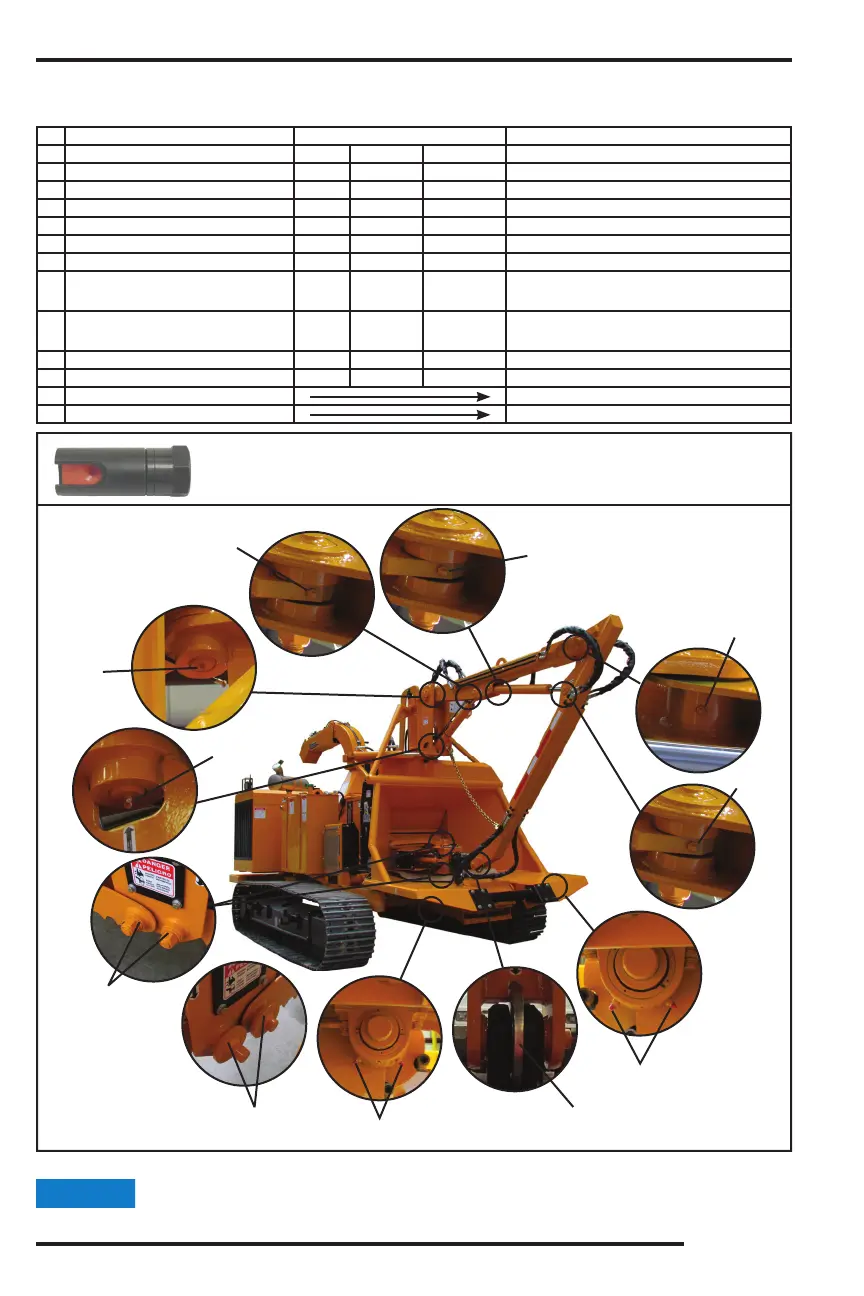

MODEL 20XP MAINTENANCE

LUBRICATION CHART - 20XP TRACK/LOADER

A right angle grease tting may need to be used to grease some of the lubrication

points. This type of grease tting can be obtained from most local automotive

parts stores.

Use as a reference only, locations may vary depending on options or component manufacturer.

Lubrication point instructions are described on the machine, in the Lubrication & Coolant

Section and Maintenance Section of this manual, or component manufacturer’s manual.

NOTICE

CHECK

# DESCRIPTION DAY WEEK MONTH PROCEDURE

1 Drum Bearings X Purge bearings daily - wipe o excess

2 Feedwheel Bearings X Purge bearings daily - wipe o excess

3 Conveyor Bearings X Purge bearings daily - wipe o excess

4 Hood Hinge X 1 - 2 shots of grease - wipe o excess

5 Feedwheel Slide Box X Clean and oil with 10W/30

6 Loader Arm & Grapple X 1 - 2 shots of grease - wipe o excess

7

Steel Friction Areas: pivoting,

hinged, sliding, rolling

X

Lubricate (i.e. discharge ipper,

s t abilizers, etc.)

8 Chain Driven Components X

Dry lube (Swivel discharge, chain

driven feedwheels, etc.)

9 Pintle Eye Ring X Grease to reduce wear

10 Discharge Swivel Plates 3 Months Grease as needed

11 Clutch

Grease per MFG’s instructions

12 Tracks Grease per MFG’s instructions

3

3

6

6

6

6

6

6

6

6

6

Loading...

Loading...