Bandit

51Copyright 12/17

MODEL 20XP

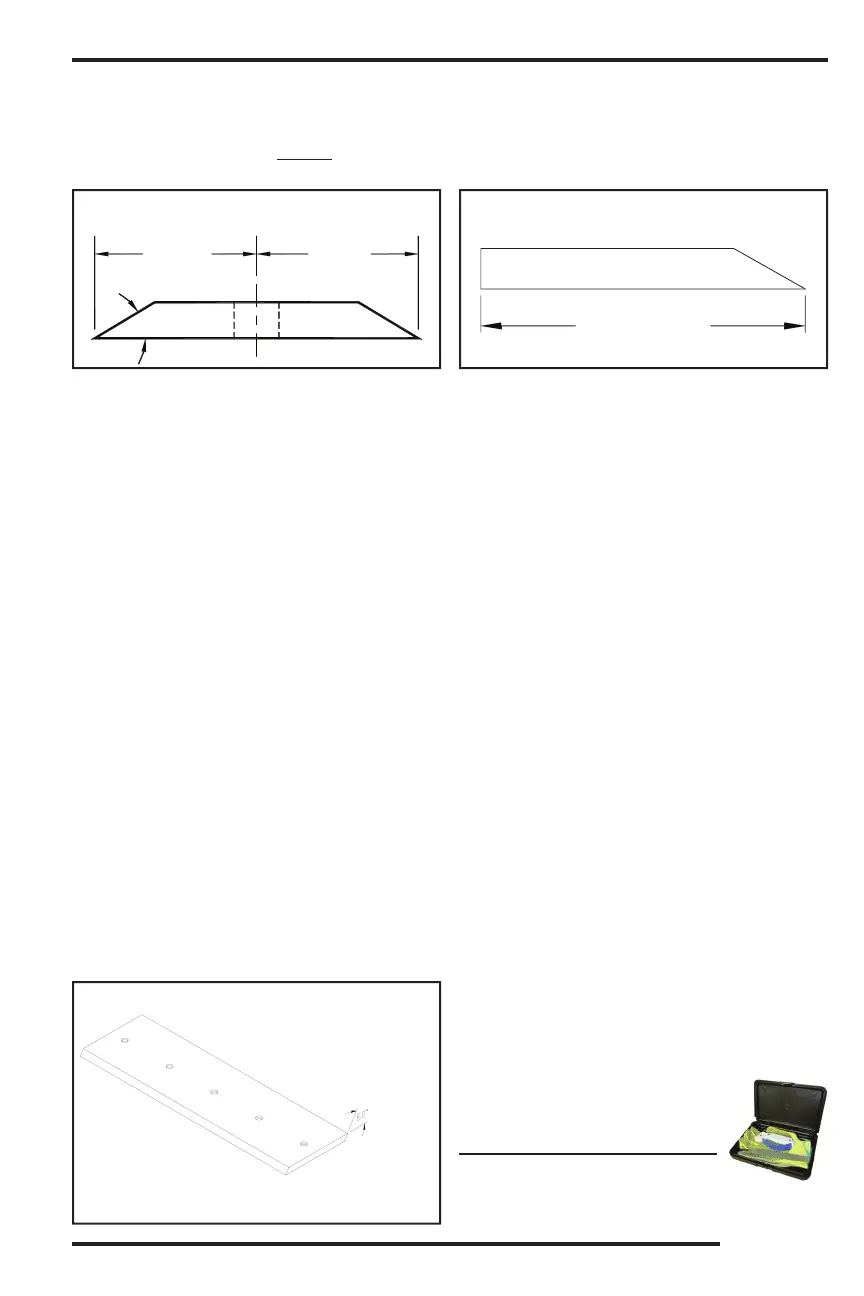

If anvil is not too worn, the two

working edges can be ground or

machined to repair.

NOTE: Make sure the anvil clearance will still be

obtainable after grinding or machining.

FIGURE 1

TROUBLE SHOOTING CHIPPER PROBLEMS

Knives should be replaced in sets. These sets are determined by the amount of resharpening done to the knives.

It should be reinstalled with another knife of comparable usage. It helps to keep the disc/drum balanced, and

it helps maintain chip quality. NEVER allow these knives to wear or be sharpened beyond absolute speci ed

minimum distance from the center line of bolt.

CHIPPER DRUM

KNIFE SAVER KIT

Through various tests, Bandit has found that using

the Knife Saver will increase the life span of chipper

knives if used during the recommended times. Each

knife installed in every new machine at Bandit has

the Knife Saver used on it before leaving the factory.

The Knife Saver can be purchased from your local

Bandit dealer.

- Use the Knife Saver on brand new knives.

- Use the Knife Saver on freshly resharpened knives.

- Use the Knife Saver every day during the Daily

Start-Up & Maintenance while the knives are checked.

- Use the Knife Saver when the machine is shut

down for a break during the day.

PART NO. DESCRIPTION

900-9901-68 Knife Saver Kit

900-9901-65 File For Knife Saver Kit Only

900-9901-63 Replacement Blades For Knife Saver

900-9901-66 Knife Changing Gloves

MAINTENANCE

1. Chipper makes poor quality chips or does not

feed properly.

A. Knives have lost their edge. File, grind or

replace knives. DO NOT operate the Bandit

with dull knives.

B. Knife anvil worn or needs adjustment. Rotate,

repair or replace (see Figure 1).

C. Feedwheel(s) are not operating correctly. (SEE

HYDRAULIC TROUBLE SHOOTING).

D. The throat/base opening is a high-wear area.

The feed plate anvil takes much of this wear

but other areas wear as well. Attention must

be paid to any areas where outer, noncutting

edges of chipper knife are exposed. These

areas must be built up with weld to maintain the

original integrity.

E. Knives are at the wrong angle. Knives must be

ground at a 30° to 30 1/2° angle.

F. Feedwheel teeth worn (REPLACE).

G. Material being chipped is very small, dry or

rotting. This type of material does not produce

good chip quality.

2. Chipper Knife Hits Anvil.

A. Check the anvil clearance at both sides of the

knife by using a feeler gauge, the clearance

should be the speci ed distance from the highest

knife (SEE ANVIL ADJUSTMENT).

B. Check the chipper bearing shaft lock nut for

tightness.

3. Discharge Plugs or Does Not Throw Chips

Properly.

A. Lugging engine on large material - keep engine

RPM up.

B. Knives are dull or worn to minimum size.

C. Obstruction in discharge chute. Patches welded

into the chute can cause obstruction of chip

ow. Anything causing an obstruction will cause

the chute to plug.

D. Chipping rotting material that has little substance

can also plug the discharge chute.

E. Worn fan blades.

4. Chipper Bearings Running Too Hot.

A. Improper lubrication - purge bearings once a

day with EP-2 Lithium type grease.

B. Chipper drum operating at too high RPM’s. DO

NOT exceed recommended RPM’s.

C. Check the chipper bearing locking collars for

tightness.

D. Bearings worn out (REPLACE).

5/8” x 5 1/2” x 12” (15.9 mm x 139.7 mm x 304.8 mm)

Chipper Knife

Min.

2 3/8”

(60.3 mm)

30°

Min.

2 3/8”

(60.3 mm)

Min.

5”

(127 mm)

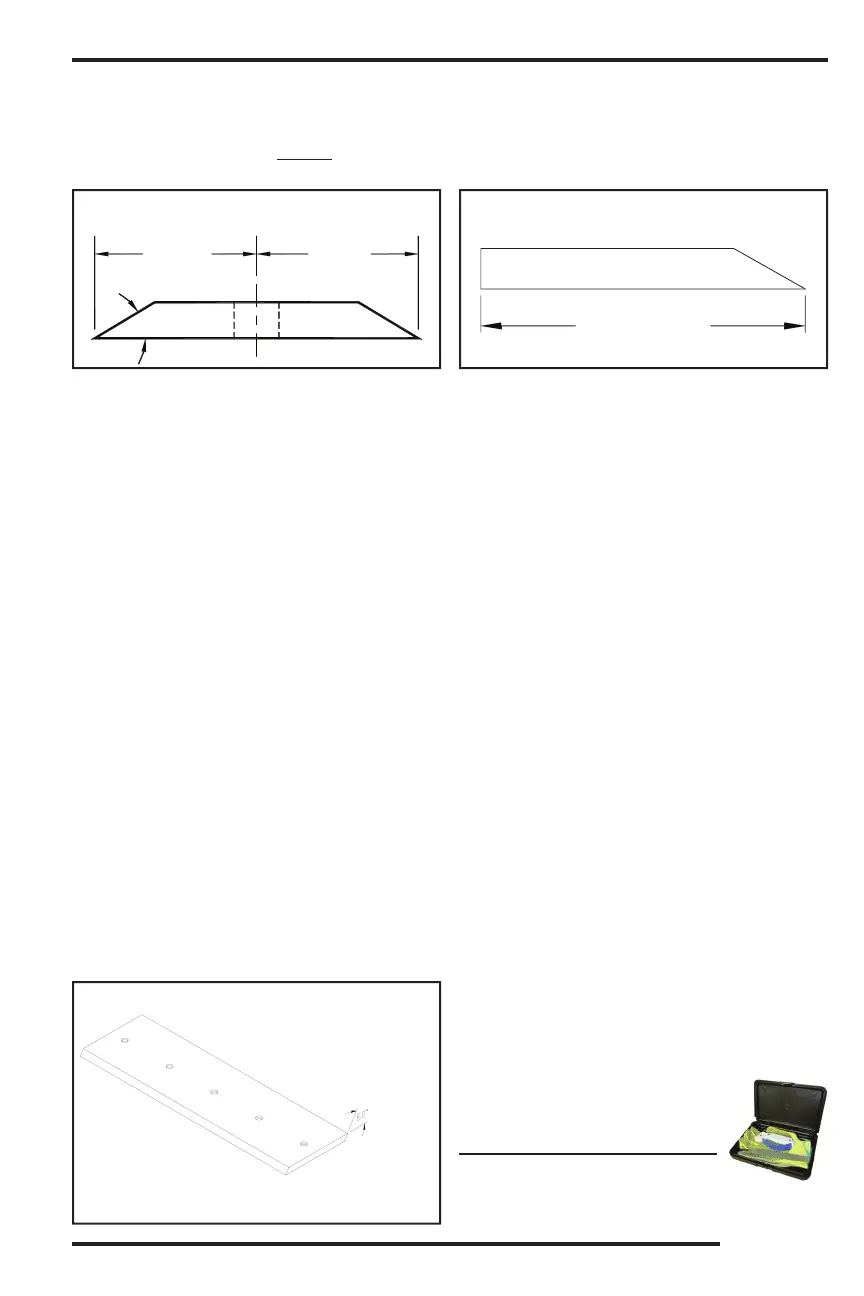

5/8” x 6” x 12” (15.9 mm x 152.4 mm x 304.8 mm)

Chipper Knife

Loading...

Loading...