Bandit

79Copyright 12/17

MODEL 20XP

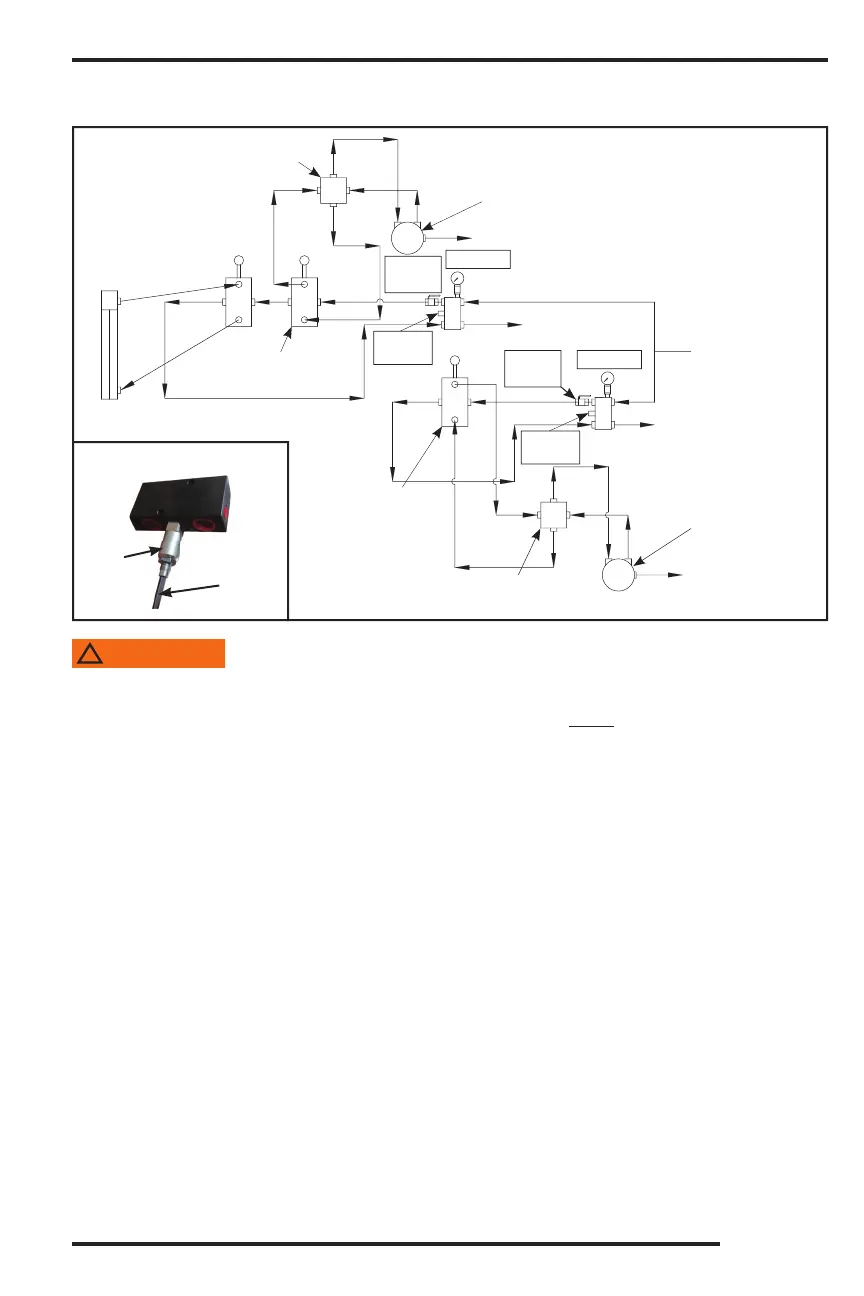

MAINTAIN FEEDWHEEL HYDRAULIC PRESSURE AT SPECIFIED PSI (bar).

Before attempting any hydraulic pressure settings, make sure engine is shut o , engine key removed and in

your possession, hydraulic oil is clean, hydraulic tank is 3/4 to 7/8 full, and the machine has been pre-run to

warm the hydraulic oil. To correctly check relief valve pressure, gauge MUST be installed correctly.

WARNING

!

1. Before attempting any type of maintenance, disengage clutch, wait for the disc/drum to come to a

complete stop, turn o engine, remove the ignition key, make sure the ignition key is in your possession,

install the disc/drum lock pin, and disconnect the battery.

2. Install pressure gauge on the test nipple that is on the main relief.

3. Start the engine.

4. Make sure the feed control is in the o position.

5. Adjust engine to full throttle.

6. Close the ball valve.

7. Pressure gauge should read maximum speci ed PSI (bar).

ONLY CLOSE BALL VALVE FOR 4-5 SECONDS TO SET PRESSURE OR YOU MAY DAMAGE

HYDRAULICS.

8. Locate the relief on the main relief block, loosen jam nut, use an allen wrench to readjust relief pressure

setting if needed, and then retighten jam nut.

9. Remove the pressure gauge and place the rubber cap back on the test nipple.

10. Check for hydraulic leaks.

11. Relief valve pressure should be checked and/or readjusted every month for best performance.

ADJUSTING THE FEEDWHEEL MAIN PRESSURE

HYDRAULICS

B

A

T

P

T

P

T

P

B

A

T

P

To Pump

To Tank

To Tank

BOTTOM FEEDWHEEL

AUTOFEED PLUS BLOCK

BOTTOM FEEDWHEEL

MOTOR

GAUGE

BALL

VALVE

BALL

VALVE

GAUGE

TOP FEEDWHEEL

AUTOFEED PLUS BLOCK

TOP FEEDWHEEL

MOTOR

YOKE LIFT

CYLINDER

YOKE LIFT

VALVE

TOP FEEDWHEEL

VALVE

BOTTOM

FEEDWHEEL

VALVE

RELIEF BLOCK

To Tank

To Tank

RELIEF BLOCK

MAIN

RELIEF

MAIN

RELIEF

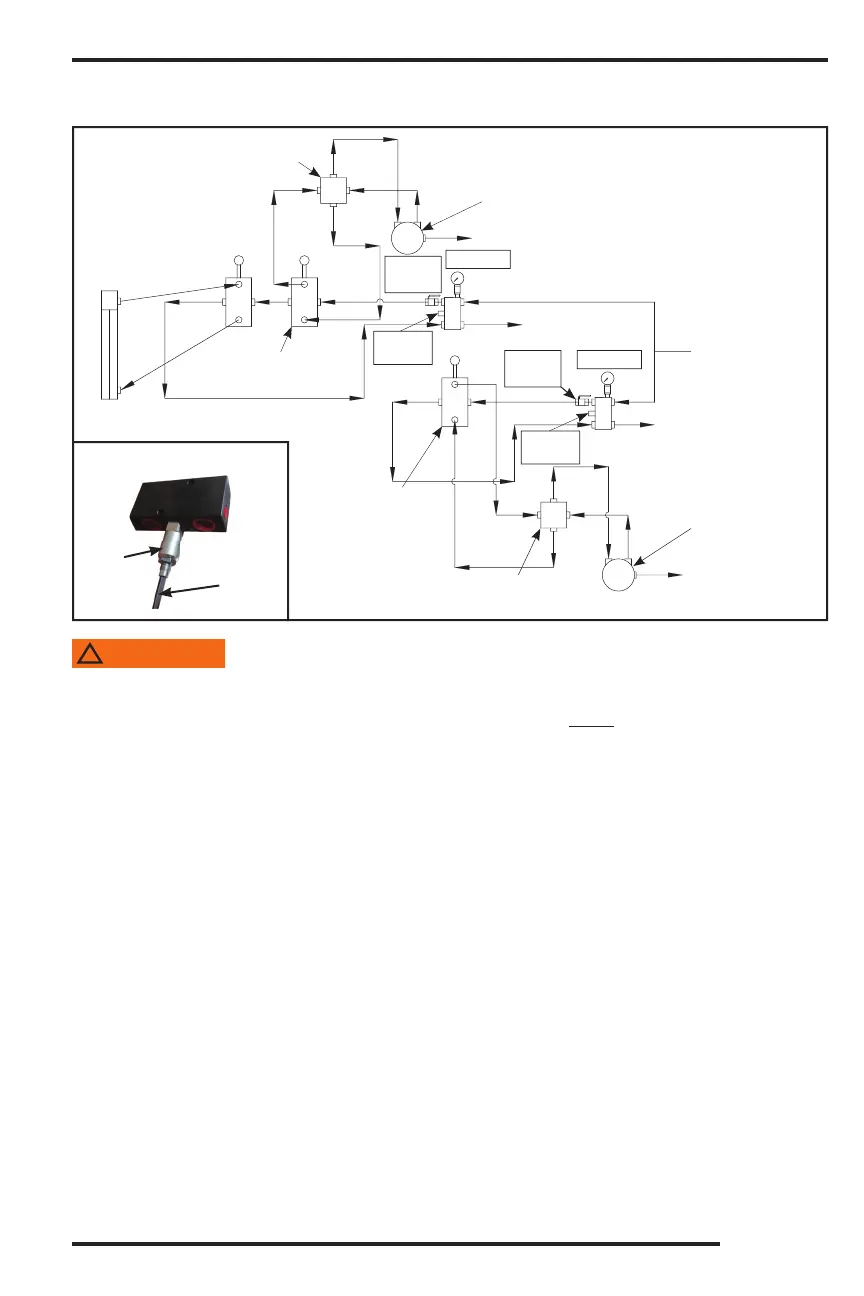

Main Relief Block

Relief

Allen

Wrench

Loading...

Loading...