1 DXM Overview

1.1 DXM System Overview

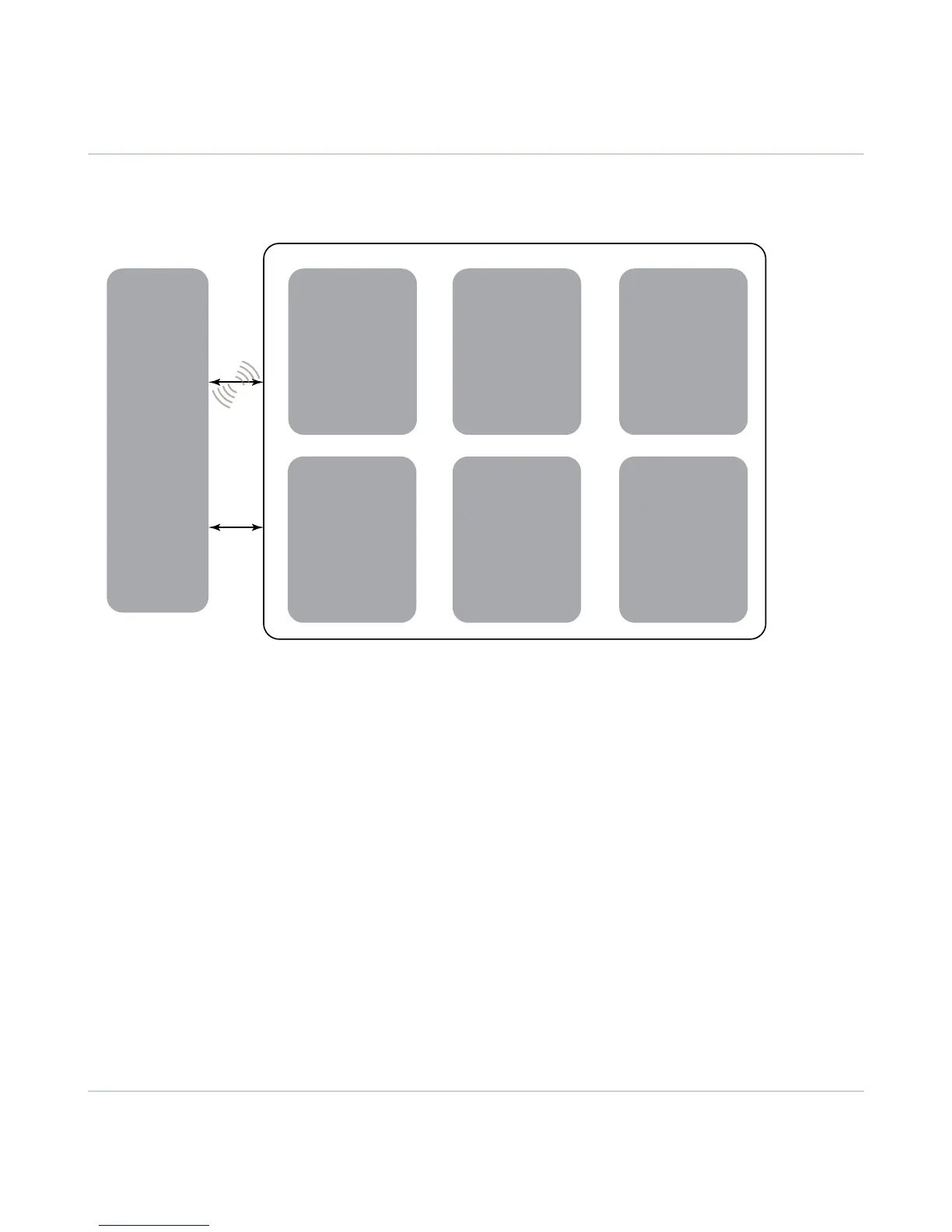

Banner's DXM Logic Controller integrates Banner's wireless radio, cellular connectivity, and local I/O to provide a platform

for the Industrial Internet of Things (IIoT).

Automation

Systems

HMI

PLC

Historian

Cloud

Sensor

Indicator

Machine

Control

Connectivity

Banner Wireless

USB

Ethernet

Cellular

RS-485 Master

RS-485 Slave

User Interface

LCD Screen

LED Indicators

I/O

4 to 20 mA

0 to 10

V

PNP/NPN Discrete

Counter

Temp

Potentiometer

Logic Controller

Action Rules

T

ext Prog. Language

Scheduler

Automation

Protocols

Modbus RTU

Modbus TCP

EtherNet/IP

Internet

Messaging

Push data to the cloud

Data Logging

SMS T

ext and EMail

HTTP API

The DXM Controller's wired and wireless connectivity

options make it easy to share data between local and remote

equipment. The cellular modem option eliminates the need for IT infrastructures to connect remote equipment for sensing

and control. The integrated Sure Cross

®

wireless radio enables Modbus connectivity to remote sensors, indicators, and

control equipment.

The DXM Controller incorporates several automation protocols into its system, including:

• Modbus RTU—Integrates into existing RS-485 serial-based Modbus-enabled automation systems.

• Modbus TCP—Uses Ethernet to attach to existing Modbus-enabled automation systems.

• EtherNet/IP—Automation systems that use the EtherNet/IP protocol can directly attach to the DXM Controller using

Ethernet.

Internet messaging tools share information generated by sensors, indicators, and control equipment with automation

systems and personnel. When Internet messaging is used in combination with the logic controller, the DXM Controller can

generate and send historical data logs, alerts, and alarms using Ethernet or cellular connectivity options. Banner's API

interface allows the user to create connections with web-based automation or business systems.

Program the DXM Controller's logic controller using action rules and text language, which can execute concurrently. The

control functions allow freedom when creating custom sensing and control sequences. The logic controller supports the

Modbus protocol standards for data management, ensuring seamless integration with existing automation systems.

On-board universal and programmable I/O ports connect to local sensors, indicators, and control equipment.

A simple user interface consists of an LCD screen and four LED indicators. Use the LCD to access system status and

setup, view user selectable events or data, and to bind and perform site surveys for Sure Cross radios. Configure the user

programmable LEDs to indicate the status of the DXM Controller, processes, or equipment.

1.2 DXM Automation Protocols

The DXM Controller supports the following automation protocols.

DXM100 Controller Instruction Manual

www.bannerengineering.com - Tel: 763.544.3164 3

Loading...

Loading...