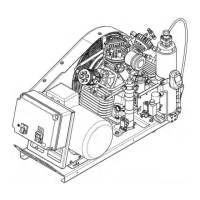

Instruction Manual Breathing Air Compressors

16

3. INSTALLATION, OPERATION, FILLING PROCEDURE

3.1. INSTALLATION OF THE COMPRESSOR UNIT

The compressor frame is equipped with anti-vibration

mounts and thus a machine base or special means of secur

ing the compressor are not necessary.

The compressor unit is not seawater resis

tant. At operation in salty air spray com

pressor with anticorrosive protection (e. g.

Quicksilver Corrosion Guard). Electric

driven units should be operated and stored

below deck. Units with petrol engine should also be

stored below deck after the filling process.

Outdoor location

For installation observe the following:

- Locate the unit level.

- On units with petrol engine it is most important that only clean air

be used, position compressor in direction of wind so that exhaust

fumes are blown away from the unit. It is good practice to have

an intake hose of at least 3 m length with pre-filter and intake fil

ter. Pre-filter to be located 2 m above ground. See Abb. 11 and

chapter 4.5.1. This arrangement will ensure necessary spacing be

tween exhaust outlet and air inlet.

Abb. 11 Outdoor location

Wind

Exhaust gas

- The use of a windvane is recommended. Turn unit as soon

as wind direction changes.

- On petrol or diesel engine, operation unit must only be lo

cated outdoors, never indoors.

- Take care that no vehicles are in direct vicinity with en

gines running.

- Do not operate unit in the vicinity of open fire (flue gas!).

Indoor location

- Ensure adequate ventilation.

- Here too, air must be free from exhaust fumes and haz

ardous vapours (e.g. smoke, solvent vapours, etc.).

- If possible install unit in such a manner that the com

pressor fan can get fresh air from outside, for instance

through an opening in the wall. Distance from wall should

be at least 0.5 meters.

Never operate petrol driven units indoors

!

3.2. ELECTRICAL INSTALLATION

For installation of electrical equipment observe the follow

ing:

- In the annex of this instruction manual you will find the

standard schematic diagrams valid for the respective

compressor unit. To connect the compressor control sys

tem, use only the diagram contained in the control box of

the unit, because any deviations from the standard dia

grams according to order are marked there.

- Observe regulations of local electricity supply company.

- Connection must be carried out by an expert only. Units

which are operated with 380/400 V are delivered with an

electric plug. All other units are delivered without a plug

and have to be equipped with a suitable plug depending

on the country.

- Ensure correct installation of protective conductor.

- Check conformity of motor and control device tension

and frequency with those of electric network.

- Adjust motor protection, thermal overload relay. For start

over contactor adjust to motor amperage rating. For start

via star-delta contactor adjust to motor amperage rating

x 0.58.

For example: motor amperage rating = 10 Amp.:

adjust relay to 10 x 0.58 = 5.8 Amp.

- Fuse motor correctly (see table below; use slow-blow

fuses, only).

Fuse table

Motor type V 12

5

23

0

24

0

40

0

41

5

44

0

50

0

60

0

66

0

3-phase, 7.5

kW

(star-delta

starting)

A 50 35 35 20 16 16 16 16 10

3-phase, 7.5

kW

(direct star

ting)

A 63 35 35 25 25 25 20 16 16

Loading...

Loading...