WARNING

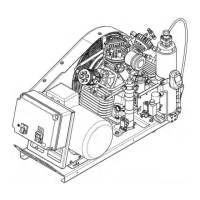

Instruction Manual Breathing Air Compressors

17

3.3. OPERATION

Preparation for operation

The compressors described in this

manual are not suitable for com

pression of oxygen. EXPLOSION oc

curs if an oil lubricated compressor is operated with

pure oxygen or gases with an oxygen content of more

than 21%!

All compressor units are tested prior to delivery

to the customer, so after correct installation of

the unit there should be no problem putting it

into operation, observing the following points:

- Prior to first operation read Instruction Manual care

fully. Make sure that all persons handling the compressor

and the filling station are familiar with the function of all

controls and monitors. Particularly observe chapter 2.

SAFETY REGULATIONS.

- Before taking unit into operation after a standstill

period of 2 years or more change compressor oil. When

using a mineral oil change oil after one year.

- Immediately after switching on the system for the

first time check the direction of rotation of the motor for

compliance with the arrow on the unit. If motor turns in

the wrong direction, the phases are not connected

properly. Shut down unit immediately and interchange

two of the three phase leads in the switch box. Never

change leads at the motor terminal board.

- Prior to first operation or operation subsequent to re

pair work operate unit for at least 10 minutes with open

condensate valves (pressureless) to ensure proper lubrica

tion of all parts before pressure is built up. To keep drain

valves open, loosen screw (3, Abb. 12) on coil (1) and pull

timer (2) from solenoid valve.

Abb. 12 Solenoid valve with timer

3

1

2

- Prior to each operation check the oil level according to

chapter 4.4.1. and determine whether maintenance is

necessary in accordance with chapter 4.3.

- Every time the unit is started up check all systems for

proper operation. If any malfunction is observed stop unit

immediately and find the cause of the fault or call the ser

vice department.

- When using extension leads or cable drums, operate unit

with unwound cable only to avoid overheating and risk

of fire. The maximum length for extension cables at nor

mal ambient temperatures (approx. 20 °C) is 25 metres.

Units with petrol engine, additionally:

- Check engine oil level according to manufacturer's in

struction manual

- Check fuel tank. Top up if necessary

- Open fuel shut-off valve.

3.4. STARTING THE UNIT

Units with electric engine without compressor control

system:

- The motor is switched on manually by pressing the start

button (1, Abb. 13).

On units with 4 kW engine without auto

matic condensate drain, the manual con

densate drain valves have to be opened be

fore starting the unit, as soon as the unit

is running the valves can be closed again.

Abb. 13 Motor protection switch

1

Units with electric engine with compressor control sys

tem:

- Place main switch (1, Abb. 14) to 1.

Loading...

Loading...