Instruction Manual Breathing Air Compressors

47

Abb. 66 DIP switch adjustment

12345 678

12345 678

A

B

ON

OFF

ON

OFF

Preliminary

setting

Final

setting

Abb. 67 Potentiometer setting

Funct

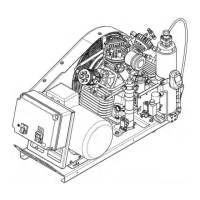

UNITS WITH PETROL OR DIESEL ENGINE

Description of drive engine see instruction manual of Honda

petrol engine or Hatz diesel engine.

4.5.12. COMPRESSOR DRIVE SYSTEM

GENERAL

The compressor is driven by the drive motor through a V-belt.

V-BELT TENSION ADJUSTMENT

On units with electric, petrol or diesel motor which are

equipped with a hinged motor plate, readjustment is not

necessary.

On units with electric motor fitted with a slide rail the motor

can be adjusted on the rail.

On units with protection frame which are equipped with a

petrol engine, the engine is mounted on a plate and can be

adjusted as necessary.

Abb. 68 V-belt pulley adjustment

After adjustment, run motor for approx. 5 minutes. Stop

motor, check V-belt tension, and readjust if required. Check

that after tension adjustment and tightening the motor

mounting nuts, both pulleys are in a straight line to avoid ex

cessive wear of the V-belt. Hold a straight edge against com

pressor and motor V-belt pulleys as shown in Abb. 68.: edge

must touch pulleys at four points, otherwise readjust motor.

4.5.13. COOLING SYSTEM

GENERAL

The cylinders of the compressor block, the intermediate

coolers and the after-cooler are air-cooled.

For this purpose, the compressor is equipped with a fan

wheel. It draws the cooling air through the fanwheel cover

from the surroundings.

Refer to chapter 3. for proper installation and cooling air sup

ply.

For maximum ambient temperature, see Technical Data,

chapter 1.

Loading...

Loading...