Instruction Manual Breathing Air Compressors

26

For operation under less severe conditions we can also rec

ommend mineral compressor oils which are suitable for oper

ation under ambient temperatures between +5 °C (41 °F)

and +35 °C (95 °F). Here also, pre-heating is required for

lower temperatures.

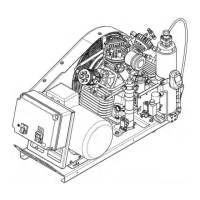

Abb. 36 Lube oil circuit

1

2

3

4

5

OIL LEVEL CHECK

Check oil level at sight gauge on either side of compressor

block every day prior to putting compressor into operation.

Oil level must be between minimum and maximum notches,

see Abb. 37. Oil level must never be below minimum mark

as this will cause severe damages due to lack of lubrication.

Oil level must also not exceed maximum as this will cause ex

cessive lubrication of compressor and result in valves sooting

up.

Maximum

Mini

mum

Abb. 37 Oil sight gauge

OIL CHANGE INTERVALS

For units equiped with B-Timer, observe

the maintenance informations on the dis

play (see chapter 3.8.).

Mineral oils every 1,000 operating hours, at

least annually

Synthetic oils every 2,000 operating hours, at

least biennially

OIL CAPACITY

Oil capacity approx. 2.8 liters

OIL PACKAGES

BAUER compressor oil is available in various quantities, refer

to oil list in the annex.

OIL CHANGE

- Run compressor warm.

- Remove red cap from oil filler neck (1, Abb. 38).

- Drain oil while still warm by means of oil drain plug. On

units equipped with oil drain hose remove hose union nut

from coupling at hose bracket. Collect oil in a suitable

container. Exchange gasket and reinstall plug.

Replace oil filter with every oil change,

otherwise the bypass valve would open if

filter is clogged, and the oil would circulate

without being filtered!

- Remove two screws (1, Abb. 39) with a 13 mm spanner.

Remove cover (2).

- Remove oil filter (1, Abb. 40) from rubber gasket at cover.

- Mount a new filter element (P/N N25326) and replace

and fasten cover.

- Fill new oil through filler neck to Max.- mark at sight

gauge.

- Pour oil in slowly, wait a few minutes, then put unit into

operation.

CHANGING THE OIL TYPE

To avoid severe damage to the compressor

unit when changing the oil type, the fol

lowing measures should be strictly ad

hered to:

- Drain oil completely while still warm.

- Check valves, coolers, separators, purifiers, and all pneu

matic tubes and hoses for deposits.

If deposits are detected, perform the following:

- Change or clean valves, coolers, separators, purifiers, and

all pneumatic tubes and hoses from deposits.

Loading...

Loading...