WARNING

WARNING

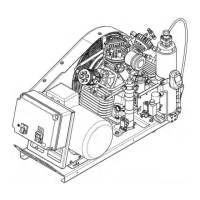

Instruction Manual Breathing Air Compressors

28

4.5.1. INTAKE FILTER

DESCRIPTION

A dry micronic filter is used to filter intake air, see Abb. 41.

Abb. 41 Intake filter

1

MAINTENANCE

The filter cartridge must be cleanded or changed at regular

intervals according to maintenance schedule in chapter 4.3.

Do not use any cleaning fluids which

are a hazard to respiration.

To clean, remove micronic filter cartridge (1) and clean with

brush or by blowing air inside out. Clean filter housing inside

with a damp cloth. Take care to prevent dust from entering

intake pipe.

INTAKE HOSE WITH PRE-FILTER

Petrol or diesel driven breathing air compressors should be

fitted with an intake hose and a pre-filter which is also recom

mended for electric power driven compressor units. It en

sures clean air, free of exhaust fumes, being compressed.

For positioning of the pre-filter refer to chapter 3.

MAINTENANCE

Change the pre-filter in the same intervals as the intake filter.

At replacement make sure that only a hose

with same length and inner diameter is

used.

4.5.2. INTERMEDIATE SEPARATOR

DESCRIPTION

An intermediate separator is mounted on the compressor

after the 2nd and 3rd stage. The separators are designed to

remove water and oil accumulating due to cooling the air

down after the compression process.

Separation is achieved by means of centrifugal action pro

vided by a vortex plate.

LIFETIME

The separators are subject to dy

namic load. They are designed for a

certain number of load cycles, which

originate from an abrupt pressure loss at condensate

drain (1 load cycle i.e. condensate drain = 1 depressu

rization, 1 pressurization). After reaching the max.

number of load cycles the separators must be replaced,

otherwise the housing may burst due to material fa

tigue. Refer to the pressure vessel operating manual de

livered with the unit.

The maximum recommended amount of four load cycles per

hour should not be exceeded. If it is possible to regulate the

operation of the unit to such a degree as to achieve four load

cycles per hour, in our opinion this would be an optimum be

tween usage and actual life.

To avoid exceeding the max. number of load cycles the oper

ating hours should be recorded in the service manual.

MAINTENANCE

Proper operation of the individual compression stages will

rely on the intermediate separator being properly serviced.

Drain condensate every 15 to 30 minutes

from the separator or ensure that the auto

matic condensate drain unit drains reg

ularly (see chapter 4.5.10.).

4.5.3. FILTER SYSTEM P31

APPLICATION AND SUMMARY DESCRIPTION

The air leaving the final stage is cooled in the after-cooler to

approx. 10 - 15 °C (18 - 27 °F) above ambient temperature

and then enters filter system P31 with TRIPLEX longlife car

tridge (Abb. 43).

The filter assembly consists of separator and cartridge

chamber. In the separator underneath the cartridge

chamber, liquid oil and water particles are reliably separated

from the compressed medium by a pipe nozzle. Residual oil

and water vapors are then removed by the TRIPLEX longlife

cartridge. The quality of the breathing air produced con

forms to DIN EN 12021.

Loading...

Loading...