31

INSTALLER Section (en)

7219623.01 (1-04/15)

10. INSTALLING THE FLUE

ducts using the accessory splitting kit.

WARNINGS

C13, C33

C53

C63 The pressure drop of the ducts must not exceed 100 Pa

C43, C83

For optimal installation, the accessories supplied by the manufacturer should be used.

To optimise operating safety, make sure the ue ducts are rmly xed to the wall with suitable brackets. The brackets must be

positioned over the joints at a distance of approximately 1 metre from one another.

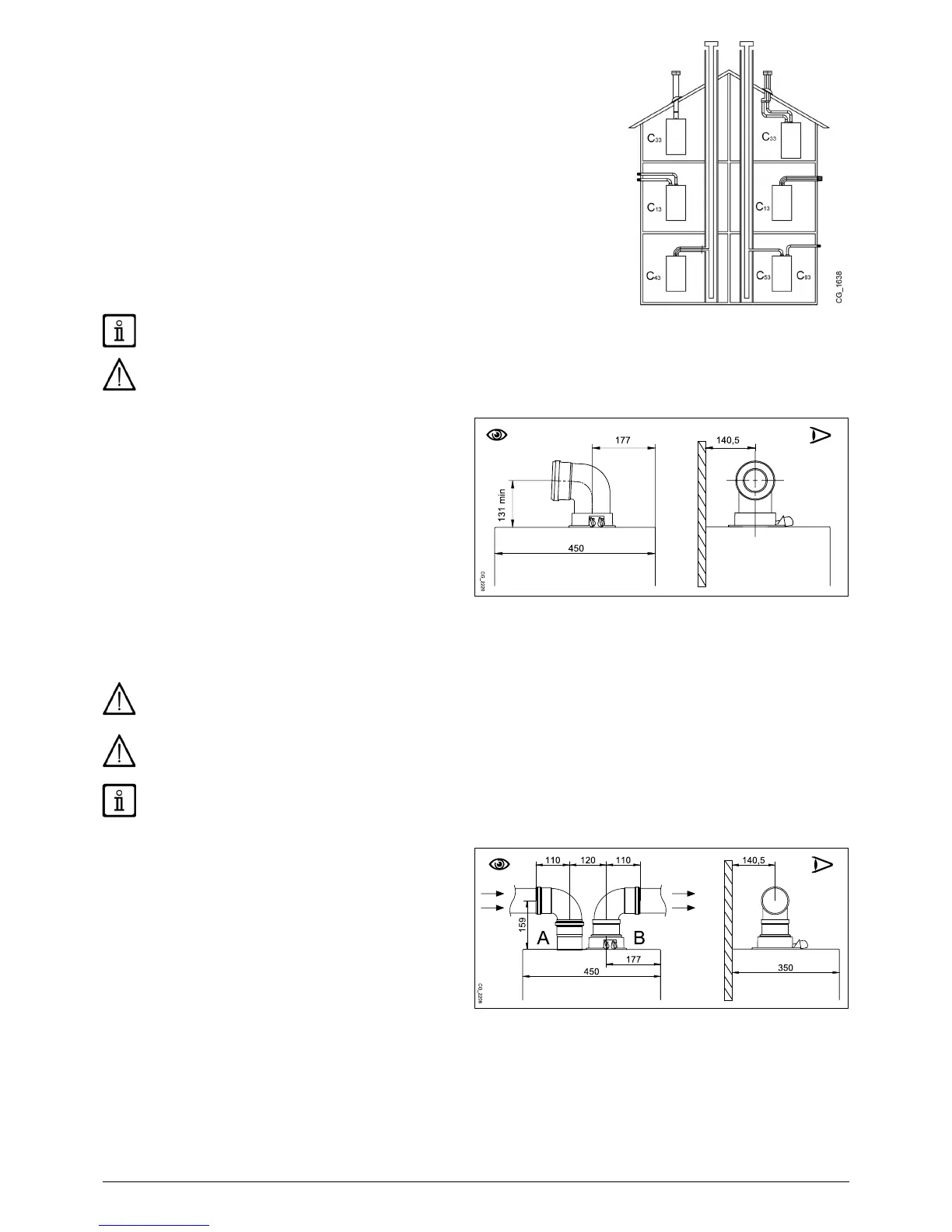

10.1 CONCENTRIC DUCTS

A 90° bend reduces the total duct length by 1 metre.

A 45° bend reduces the total duct length by 0.5 metres.

The rst 90° bend is not included when calculating the maximum available length.

Before securing the screws, make sure that at least 45 mm of the pipe is inserted into the gasket (see the gures in annex

"SECTION" D at the end of this manual).

Make sure there is a minimum downward slope of 5 cm per metre of duct towards the boiler.

SOME OUTLET DUCT INSTALLATION EXAMPLES AND THEIR RELATIVE MAXIMUM LENGTHS ARE SHOWN IN ANNEX

"SECTION" D AT THE END OF THIS MANUAL.

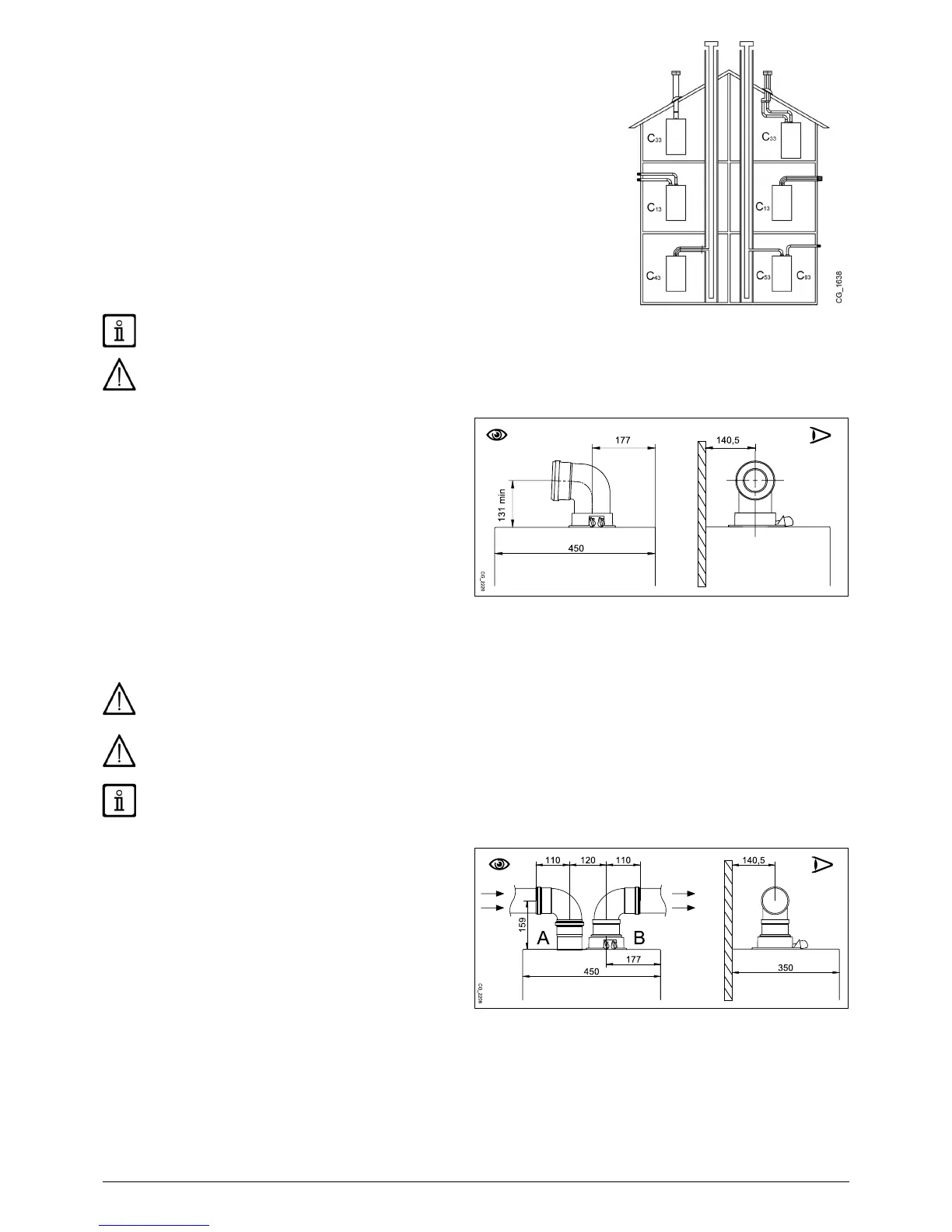

10.2 SEPARATE DUCTS

This type of installation makes it possible to discharge exhaust

B) and an air duct adaptor (A). For the

from the cap.

outlet ducts, adapting them to various requirements. It can

A 90° bend reduces the total duct length by 0.5 metres.

A 45° bend reduces the total duct length by 0.25 metres.

The rst 90° bend is not included when calculating the maximum available length.

Loading...

Loading...