11

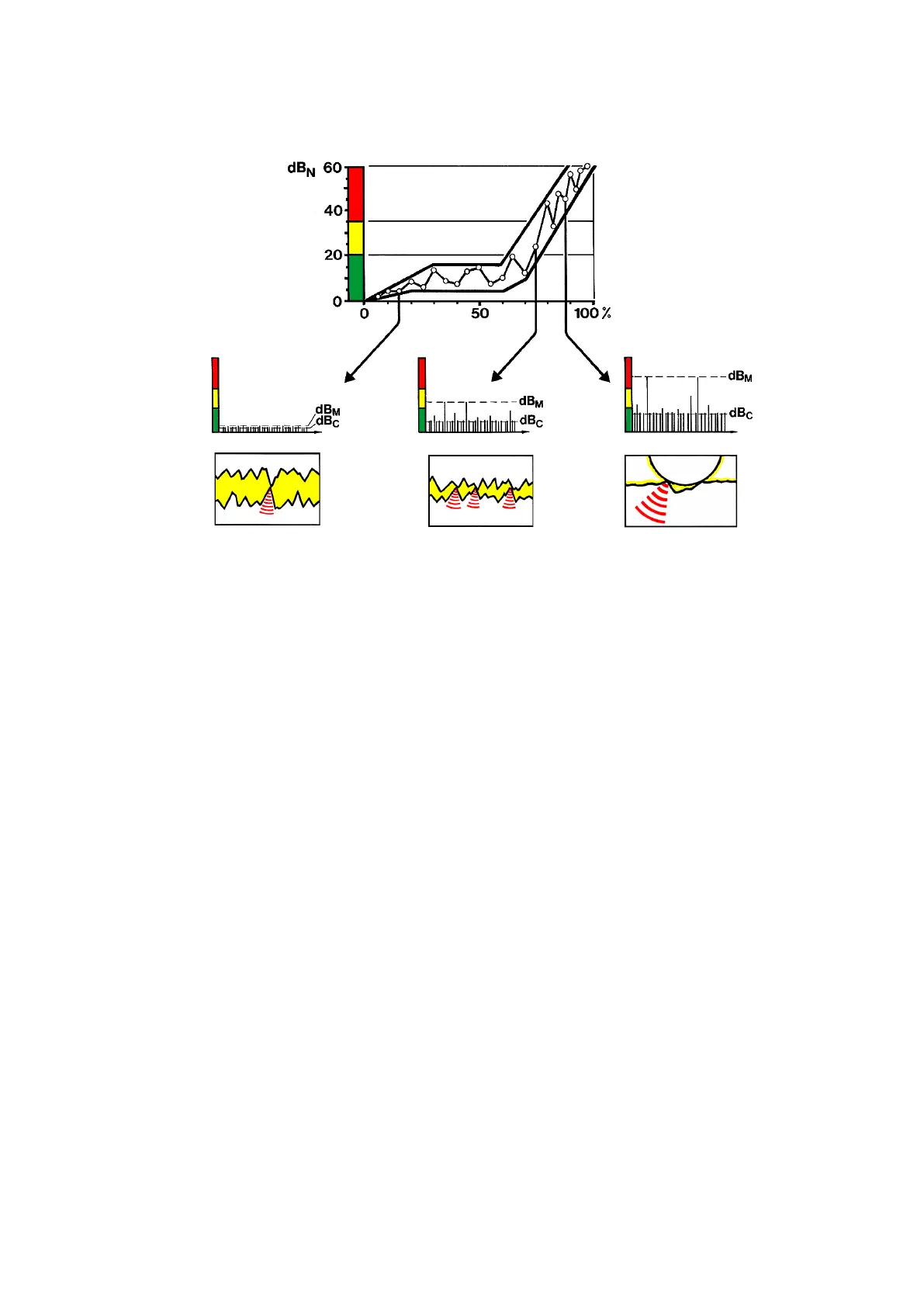

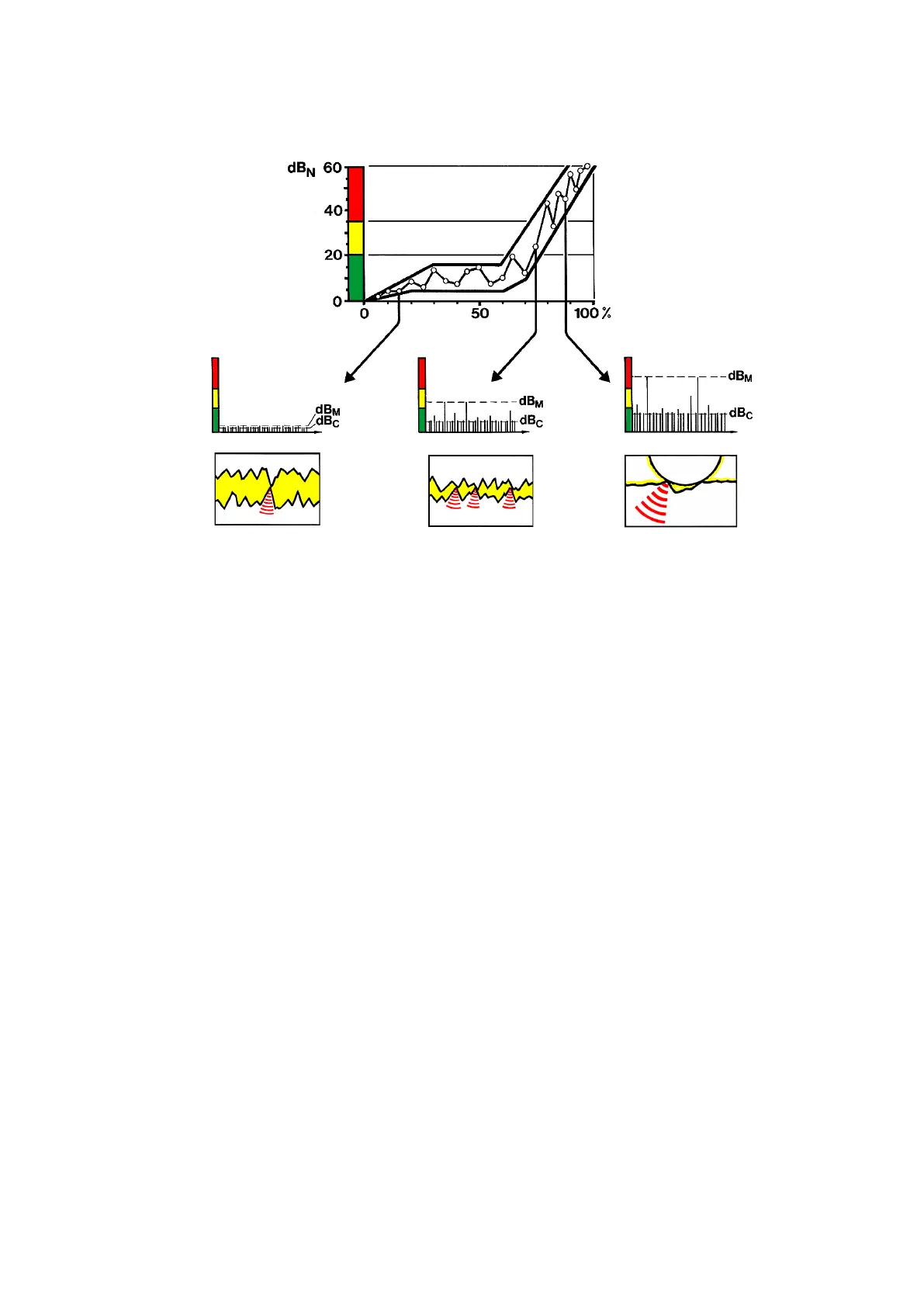

The dBm/dBc technique

The dBm/dBc technique is well established and well suited for industrial condition monitoring, working

with few, easy to understand in- and output data.

Even on a logarithmic scale, there is normally a large, distinct difference between the maximum values

from good and bad bearings. Thus, minor inaccuracies in the input data (rpm and shaft diameter) have

little effect on the evaluated measuring result.

Lubrication condition is indicated by the delta value, i.e. the difference between dBm and dBc. High readings

and a small delta value indicate poor lubrication or dry running. This is sufficient for maintenance purposes.

dBm and dBc are measured in a fixed time window and automatically displayed.

The headphone is used to listen to the shock pulse pattern in case of suspect or high readings. This, and

the possibility to search for shock pulse sources with the probe transducer, are means to verify the measur-

ing result and its cause.

Life time

Loading...

Loading...