12

The guidelines for the selection of shock pulse measuring

points have a very practical purpose. The aim is to capture

low energy signals, which are getting weaker the farther they

travel and the more they are bounced about inside a piece of

metal. We know that they lose strength when they cross over

from one piece of metal to another. We cannot know, for all

bearing applications, how much of the strength of the signal

emitted by the bearing will reach the measuring point. How-

ever, by necessity we try to apply general evaluation rules, i. e.

treat all measured signals as if they were of the same quality.

The rules for shock pulse measuring points try to assure that

most of them are ”within tolerance” and that the green-

yellow-red condition zones are valid:

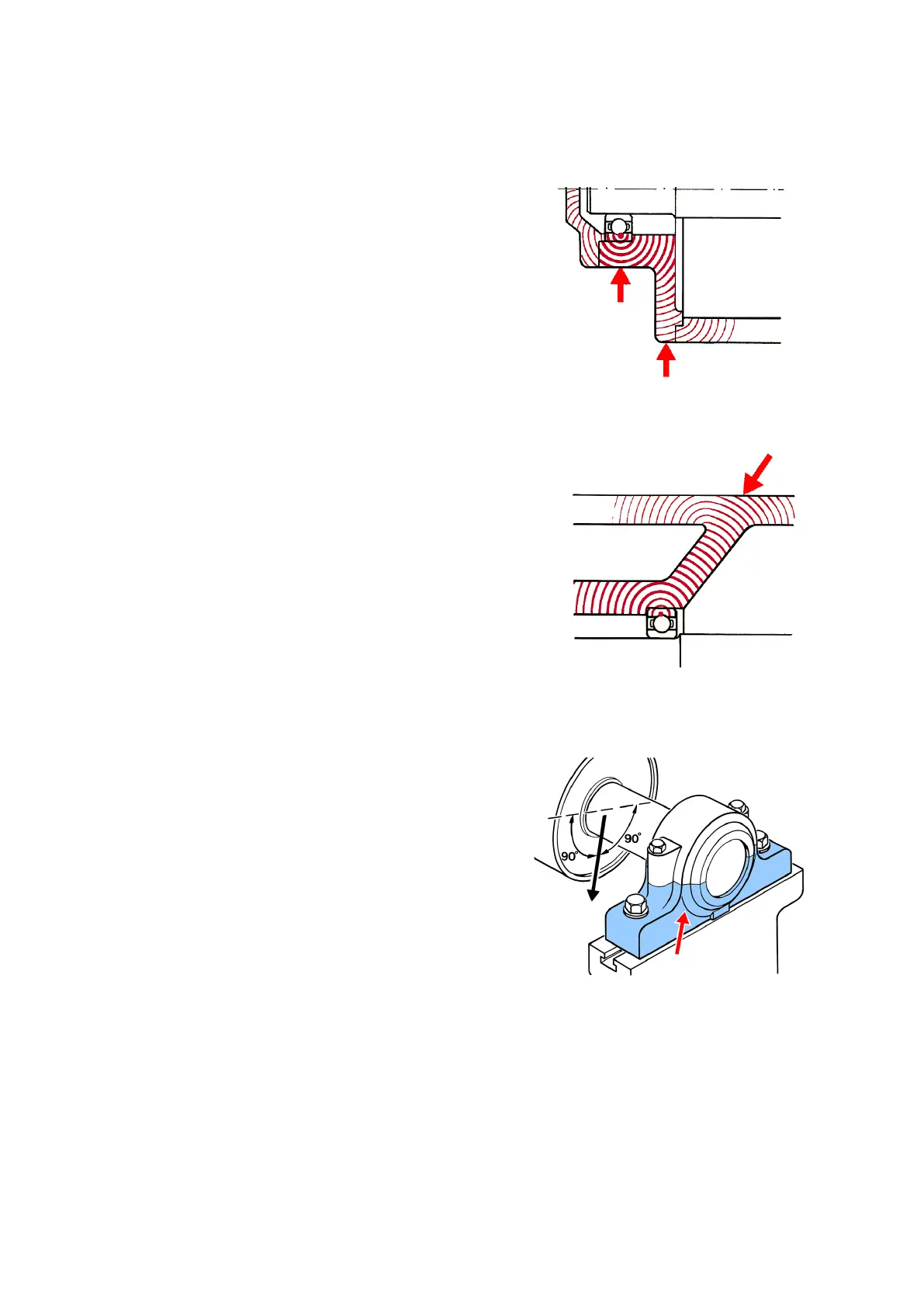

1 The signal path between bearing and measuring

point shall be as short and straight as possible.

2 The signal path must contain only one mechanical

interface: that between bearing and bearing housing.

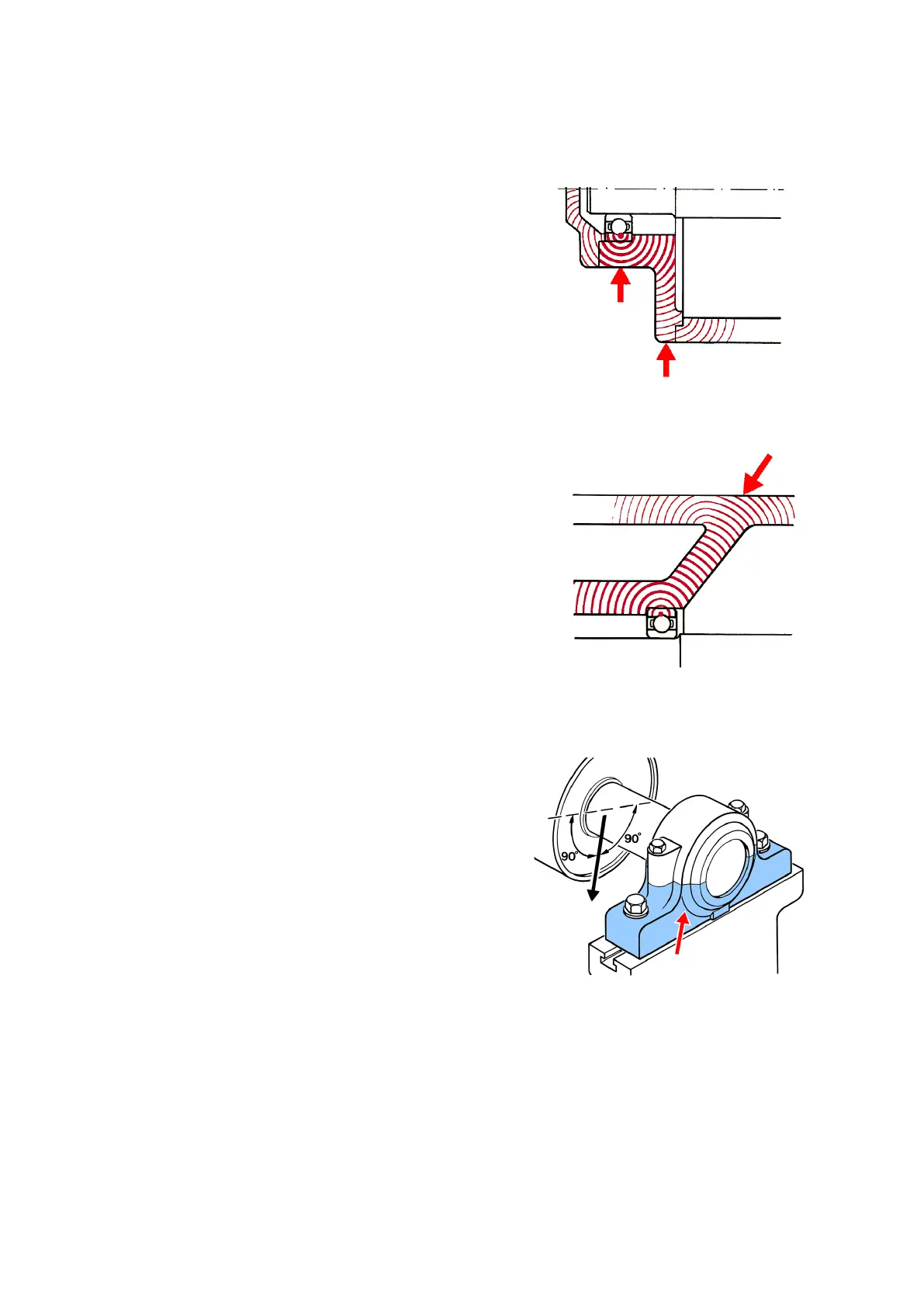

3 The measuring point shall be located in the load zone

of the bearing.

“Short” means up to 75 mm (3 in.), but that depends also

on how straight the path is: bends cause re- and deflections

whose effects are hard to judge. The load zone is the load

carrying half of the bearing housing, normally the lower one.

Allow for the pull of belts or other forces which can shift the

load to one side. Use the probe to find the spot yielding the

strongest signal. When a measuring point cannot conform to

the rules (because an ideal spot cannot be reached), make

allowance for a weaker signal.

Measuring

point

Load

1. Straight and short path

2. No interface!

3. In the load zone of the

bearing

Guidelines for measuring points

Loading...

Loading...