26

Sources of interference

Any kind of metallic clatter, hard impacts or scraping produces shock pulses which may interfere with the

measurement on the bearings. Some of the more common sources of interference are:

• Shocks between poorly fastened machine feet and foundation.

• Rubbing between shafts and other machine parts.

• Loose parts striking the machine frame or the bearing housing.

• Excessive play and misalignment of couplings.

• Vibration in connection with loose parts and excessive bearing play (vibration alone does not affect

the reading).

• Cavitation in pumps.

• Gear tooth damage.

• Load and pressure shocks arising during the normal operation of certain machines.

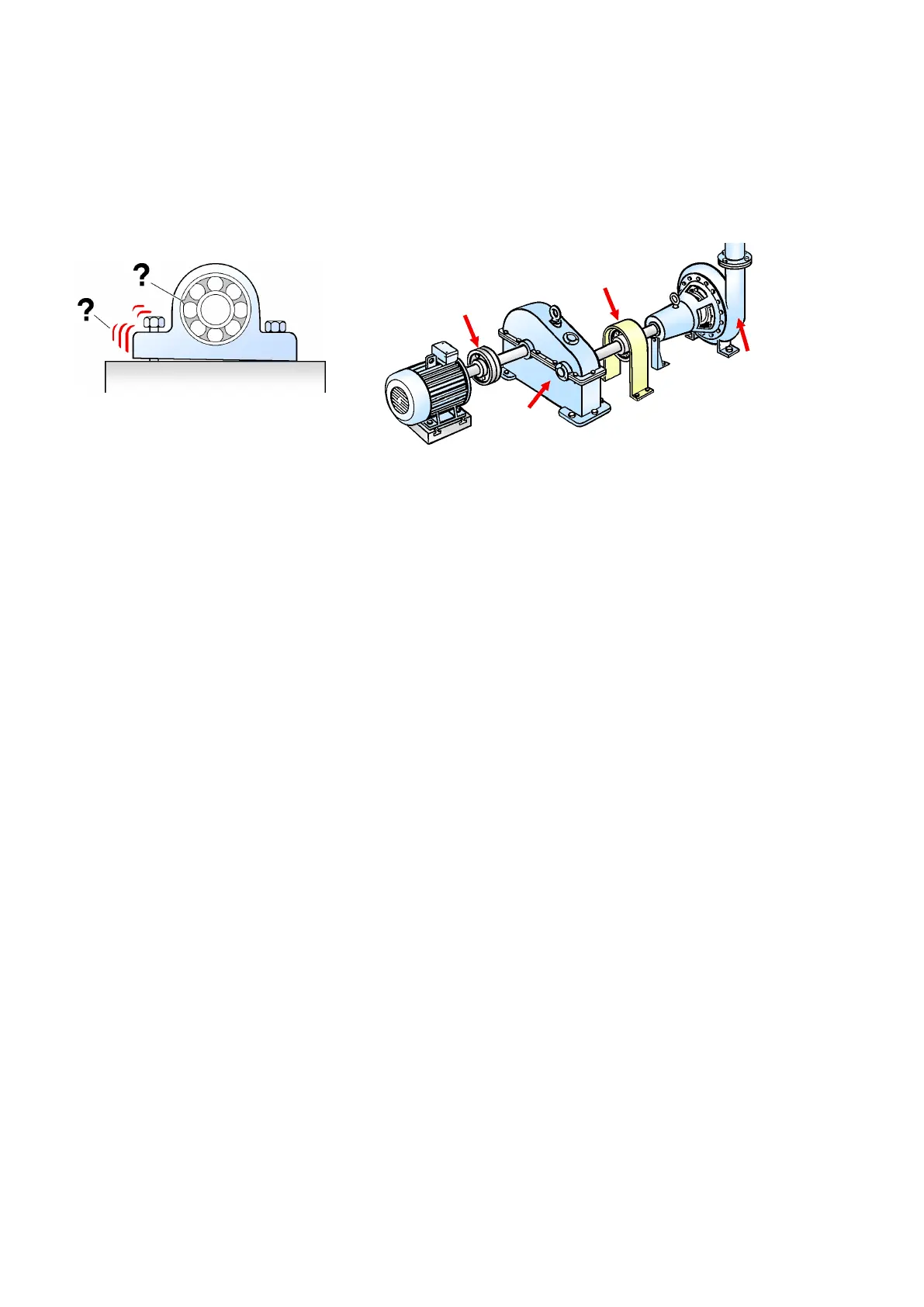

Identifying the shock pulse source

Excessive

play

Gear tooth

damage

Cavitation

Play,

scraping

Shock pulses are strongest close to the source. They spread through the material of all machine parts, but

are dampened (loss of signal) with distance and when passing through interfaces in the material.

• Measure on and near the bearing housing to find the strongest shock pulse source.

• Listen for unusual noises.

Loading...

Loading...