32

On receiving the typical bearing damage signal – high dBm, large

difference between dBm and dBc, random peaks, strongest signal

on the bearing housing – you must confirm one of the following

causes for the reading:

• tapping of loose parts against the bearing housing

• excessive bearing play in combination with vibration

• particles in the lubricant

• bearing damage

Interference can usually be detected by a careful inspection.

Lubrication test

A lubrication test is the best means to reach a conclusive verdict:

• Make sure that the lubricant is clean and not contaminated.

• Lubricate the bearing and repeat the measurement. Meas-

ure immediately after lubricating and again a few hours later.

Make sure that the lubricant reaches the bearing. Typically, you

will get the following results:

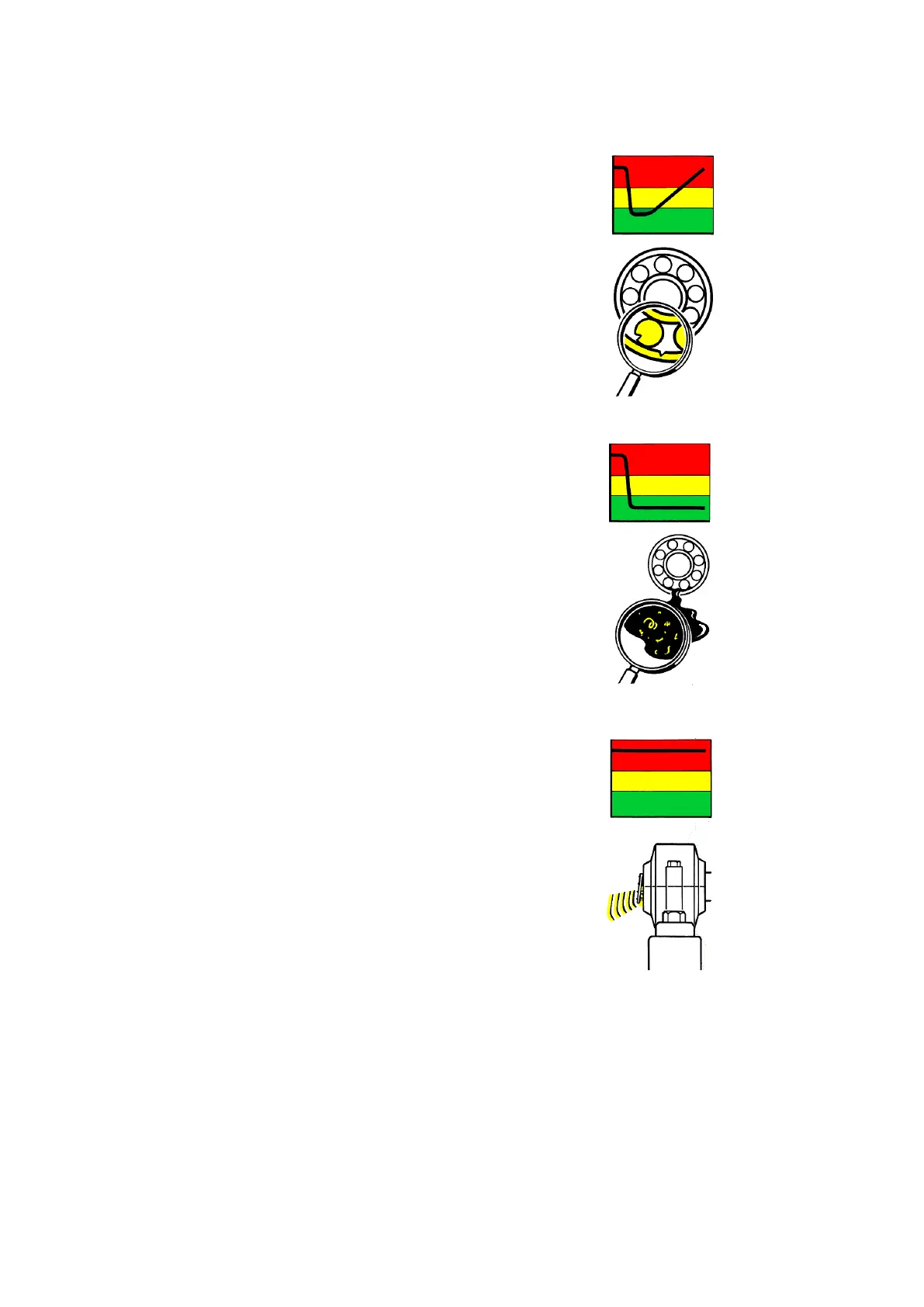

A The shock pulse level remains constant. The signal is caused

by interference or cross talk from another bearing.

B The shock pulse level drops immediately after lubricating

and remains low. Foreign particles in the bearing were re-

moved by the fresh lubricant.

C The shock pulse level drops immediately after lubricating but

rises again within a few hours. The bearing is damaged.

Note that metal particles in the lubricant can originate from the

bearing itself. Measure the bearing again over the next few days

and make sure that the values stay low.

Confirming bearing damage

Loading...

Loading...