31

6 Large drop in the readings

If the shock pulse level drops after a sequence of normal

readings, you have either a malfunction of the instru-

ment, a failure in a transducer installation, or a serious

bearing fault.

Check the instrument by measuring on some other

bearing. In case of an installed transducer, try to get

a reading by tapping on the bearing housing. If your

reading is correct, it is possible that one of the bearing

races is slipping, either on the shaft or in the housing. In

case of a heavily loaded bearing with previous readings

in the red zone, suspect cage failure.

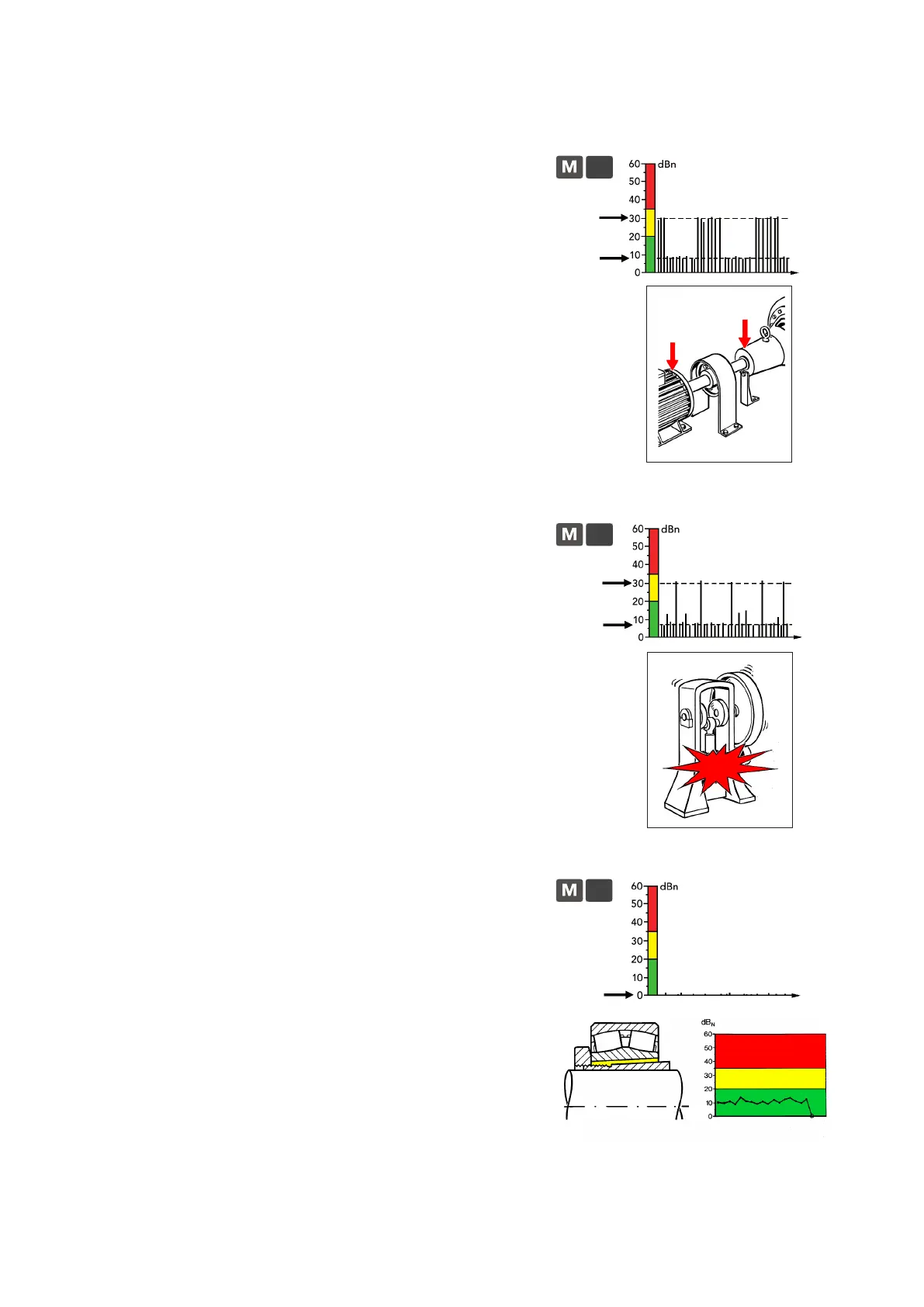

5 Rhythmical peaks

Single, rhythmical peaks can be caused by load and

pressure shocks which occur during the machine’s

normal operation. Other possible causes are clicking

valves or loose parts knocking regularly against the

machine frame.

If the signal is strongest on the bearing housing, you

can suspect a cracked inner ring.

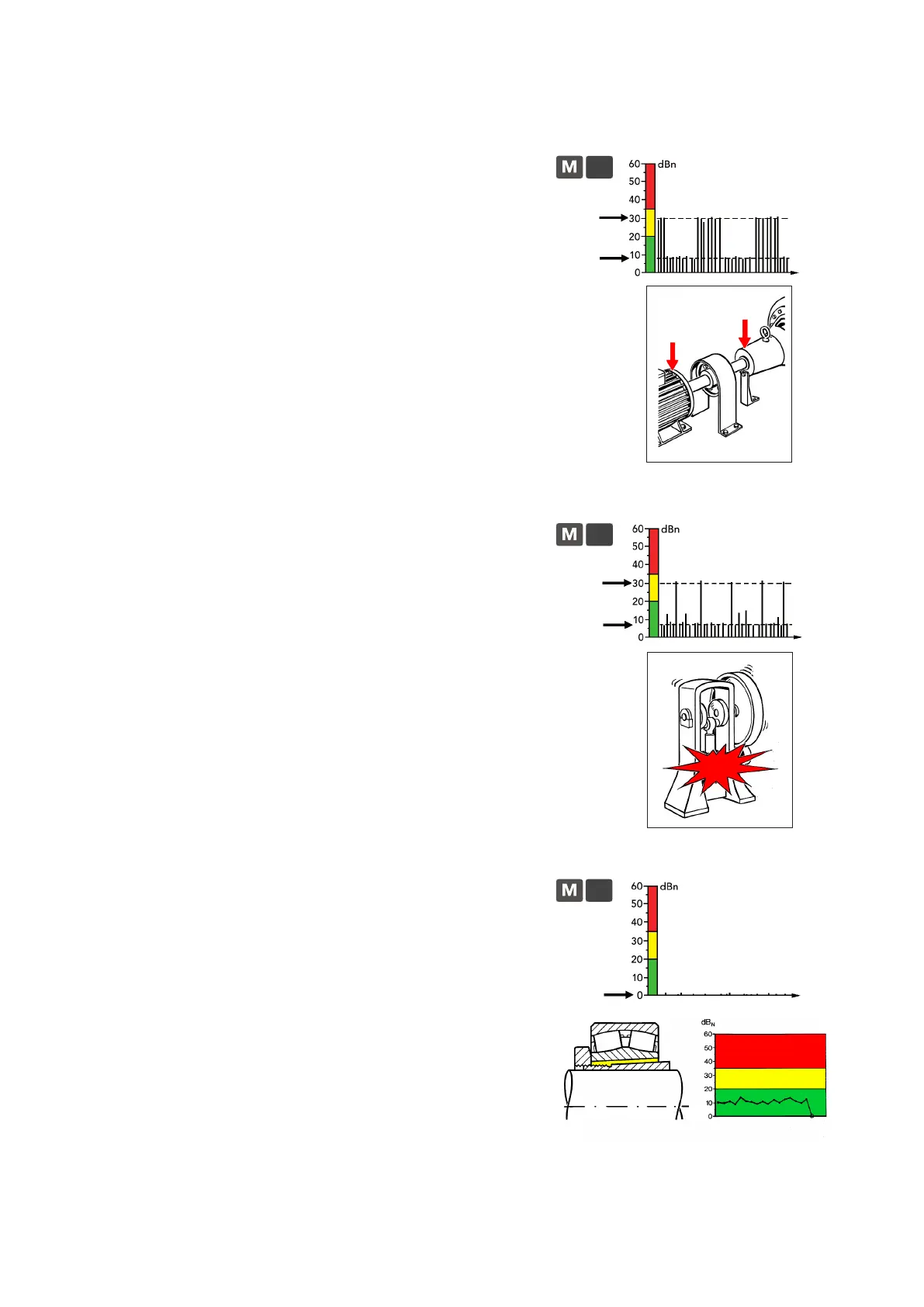

4 Periodic bursts

Periodic bursts are a typical interference signal, caused

by rubbing between machine parts, e.g. shaft against

bearing housing or seal. The burst occurs at an rpm

related frequency.

dBm

dBc

dBm

dBc

Loading...

Loading...