2

TLT

M

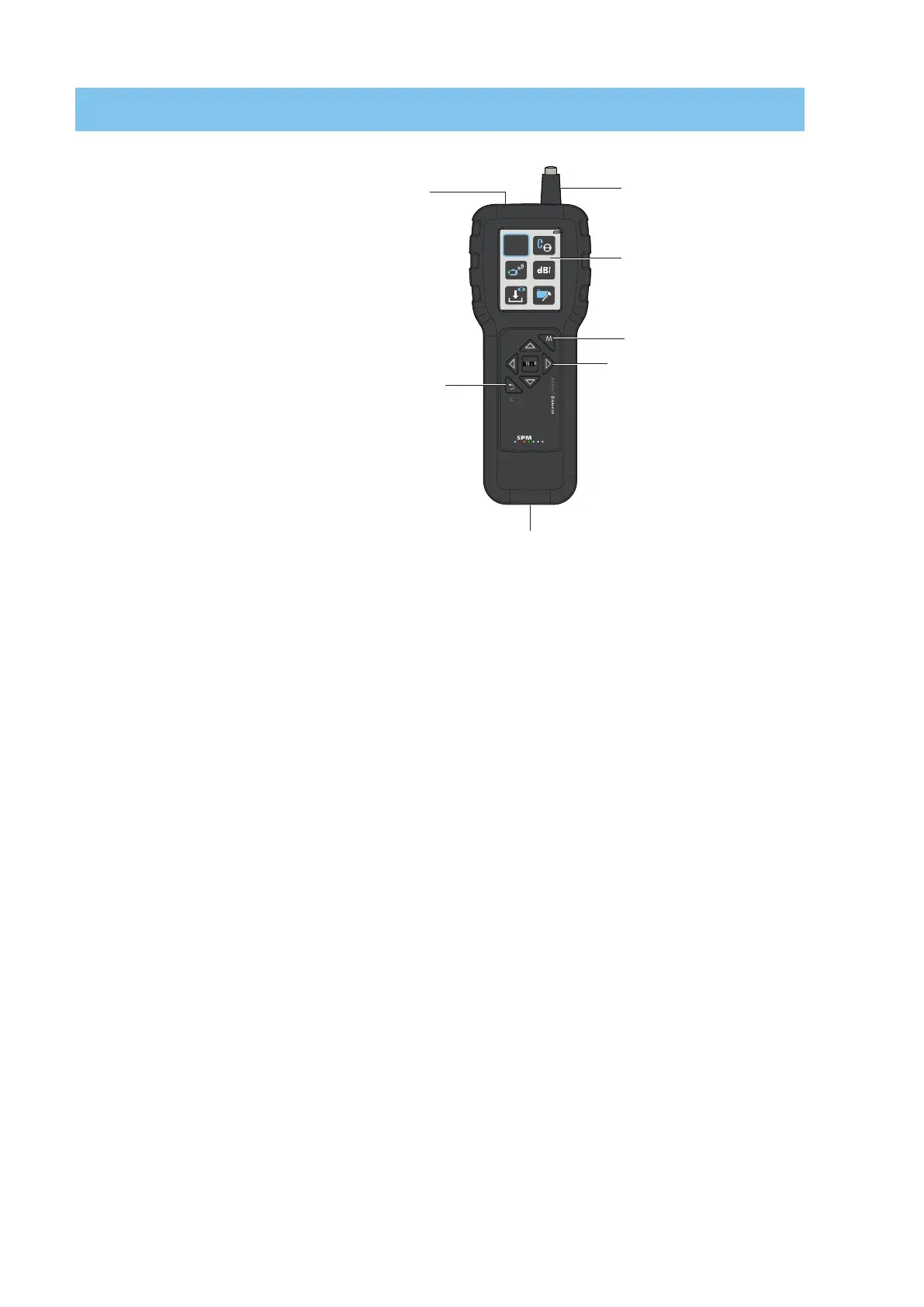

Instrument parts

1 Measuring probe (BC200)

2 Transducer input (BC200/BC250)

3 Graphical display with LED backlight

4 MEASURE key

5 Navigation keys

6 BACK key and power on

7 Mini-B USB communication output

Instrument Overview

General description

The BearingChecker is a shock pulse meter based on the well-proven SPM method for quick and easy

identification of bearing faults. The instrument has a built-in microprocessor programmed to analyze shock

pulse patterns from all types of ball and roller bearings and display evaluated information on the operating

condition of the bearing.

BearingChecker is lithium-ion battery powered and designed for use in harsh industrial environments. The

graphical display (3) displays the condition readings and provides an immediate evaluated bearing condi-

tion in green-yellow-red, with a short explanation regarding the evaluation.

For BC200, the probe type shock pulse transducer (1) is built-in. For BC200 and BC250, external SPM shock

pulse transducers of types 40000 and 42000 for adapters and permanent installation can be used as well,

connected to the transducer input (2). The dBi value is programmed into the instrument and measurement

is started with the ‘M’ key (4). The actual condition reading is displayed on the graphical display (3) as a

carpet value (dBc), and a maximum value (dBm). The evaluated bearing condition is indicated in the form

of a green, yellow or red status icon, with a condition code on a scale from 1 to 6. Headphones for listening

to the shock pulse pattern can be connected to the USB output (7) using a headphone adapter (optional).

The BearingChecker can also be used for detecting machine sound irregularities via headphones using the

Stethoscope function.

Built-in or external probes can be used for listening.

1

3

2

4

5

7

6

Loading...

Loading...