13

The following two pages show measuring points and possible

adapter or transducer installations. How to install measuring

equipment is described in the SPM installation manual.

Through hole for long adapter

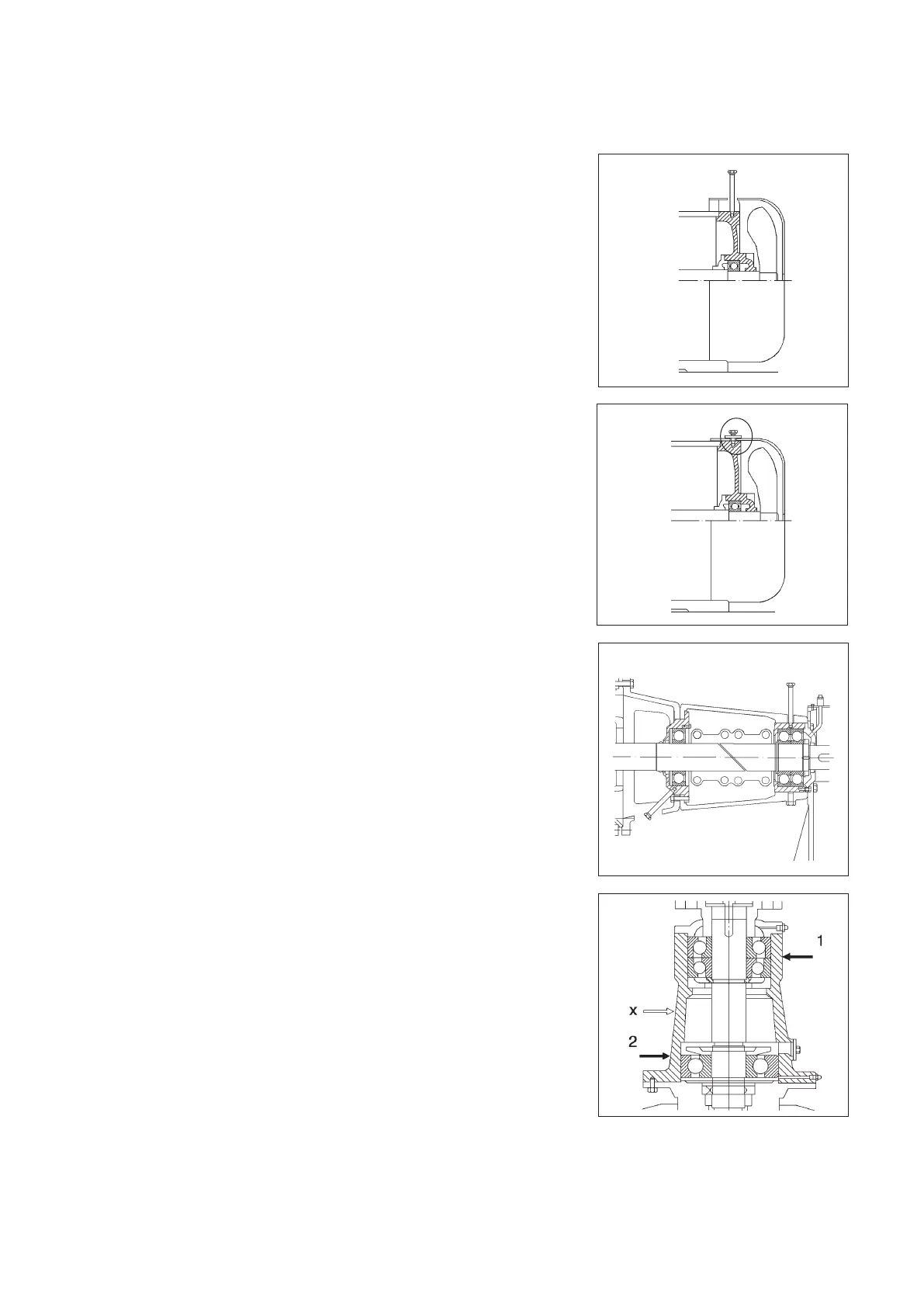

Figure A shows how a measuring point beneath a fan cover

can be reached with a long adapter, through a hole in the

cover.

Adapter with lock nut

In figure B, the fan cover is fastened directly to the motor

shield, which is also the bearing housing. One of the cover’s

holding screws can be replaced by an adapter with lock nut.

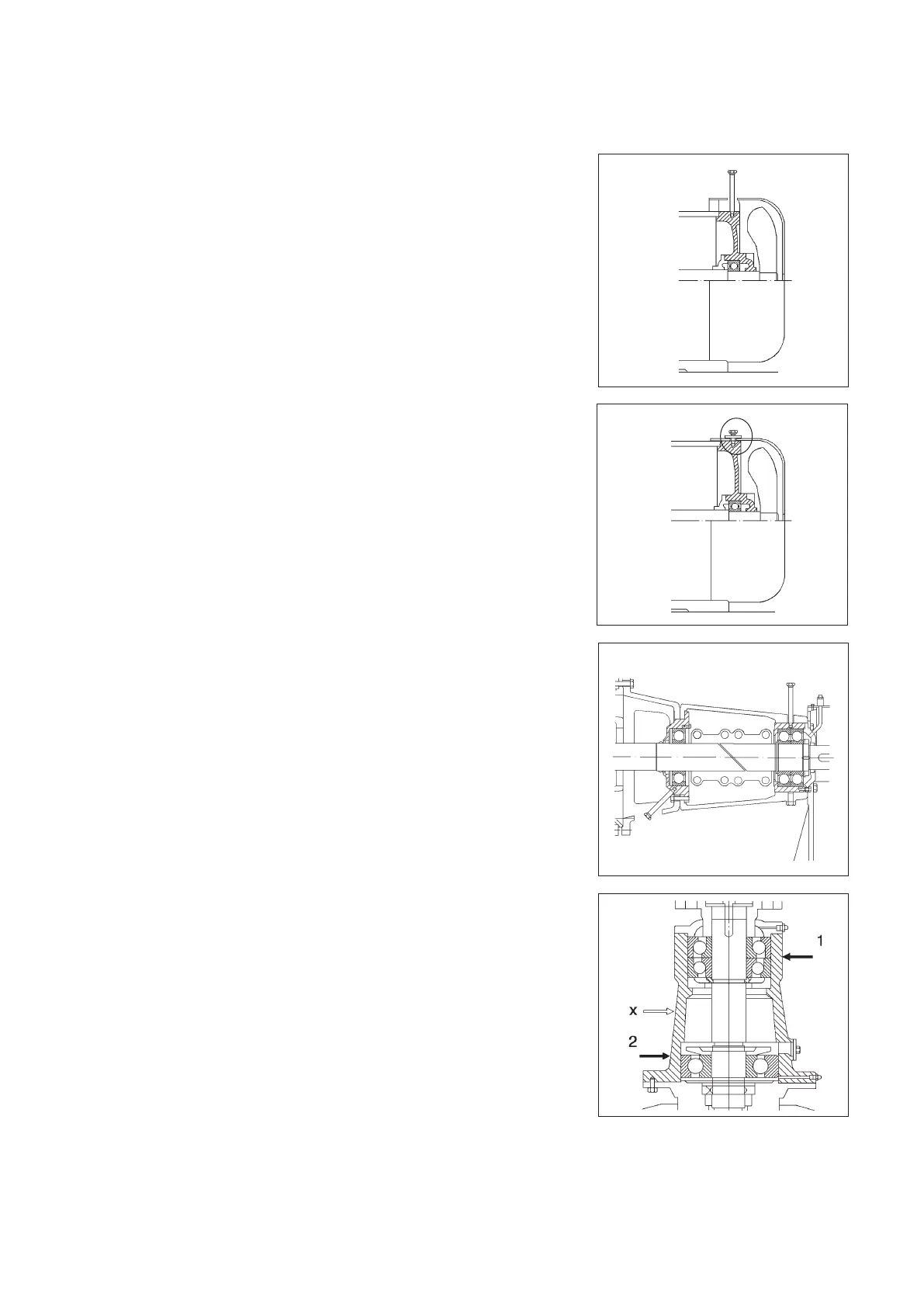

Bearing housings beneath brackets

Consult machine drawings and identify the bearing housing

before selecting a measuring point.

In figure C, showing a pump, the bearings are placed in two

separate housings inside the bearing bracket.

The bearing pair at measuring point 1 can be reached with

a long adapter through a clearance hole in the bracket. The

hole must be large enough to allow bearing adjustment and

still prevent metallic contact between bracket and adapter.

Measuring point 2, placed below and opposite to the pump

outlet (load direction!) can be reached with a long adapter

through an opening in the pump shield.

Multiple bearings in one housing

If there are several bearings in the same housing, they are

normally treated as a single bearing. Figure D shows the

bearing arrangement for a vertical pump. It is not possible

to distinguish between the shock pulses from the paired

bearings in point 1.

There is also a risk for cross talk between point 1 and point

2, which means that the shock pulses from the bearing in

worst condition are picked up at both points. Check signal

strength with the probe. Use one measuring point only if

readings are identical in both points. This point (x) can be

placed halfway between points 1 and 2.

A

Measuring points, examples

1

2

C

B

D

Loading...

Loading...