14

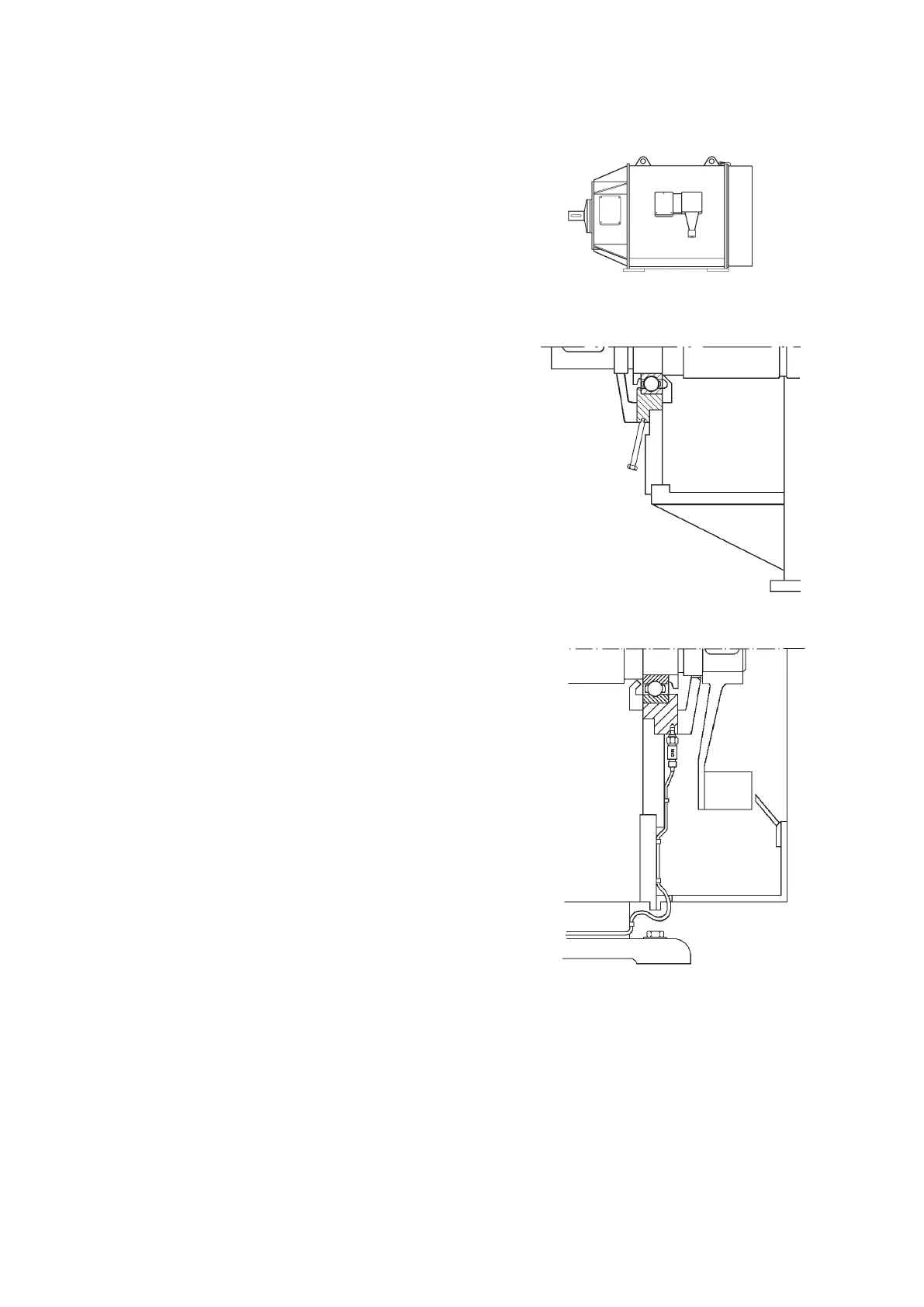

On large electric motors, the bearings are often mounted in

housings which are welded or bolted to the motor shields.

Because of the damping in the interface between the bushing

and the shield, the measuring point should be on the bushing.

The bearing housing at the drive end (A) is usually within reach.

A long adapter is installed at an angle to the shield, so that

there is enough space for connecting the transducer.

Installed transducer

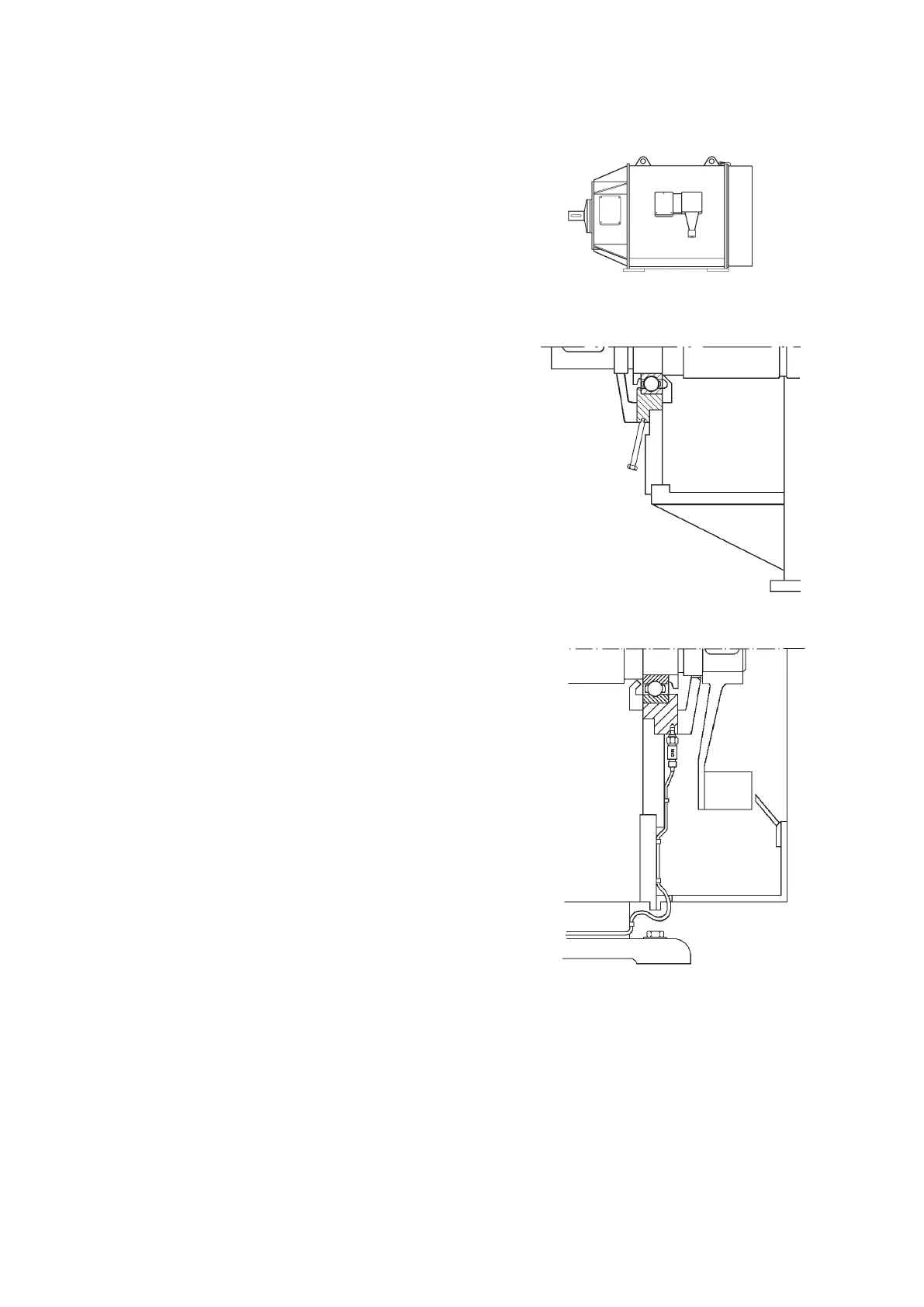

The bearing at the fan end (B) requires a permanent trans-

ducer installation. The transducer is installed in the bushing.

The coaxial cable is run through a slit in the fan cover to a

measuring terminal on the stator frame.

Check installed equipment

Incorrectly installed adapters or transducers can cause a sig-

nificant damping of the shock pulse signal.

Check all installations. Make sure that mounting holes are

correctly countersunk and that the seat surfaces of adapters

have good contact with the material of the bearing housings.

Any metallic machine part knocking or rubbing against the

adapter will produce a disturbance. This must be avoided by

making large clearance holes and using soft, elastic sealing

material.

Use high-temperature cables and moisture-proof equipment

where required, and protect installations against damage.

Adapters should be fitted with protective caps.

Mark the measuring points

Measuring points for the probe transducer should be clearly

marked. To get comparable readings, one must always use

the same measuring point.

A

drive end

A

B

B

fan end

Loading...

Loading...