15

The measuring range of the BearingChecker is large and

covers most bearing applications, but there are a few cases

where shock pulse monitoring should only be attempted with

installed measuring equipment, or not at all.

High-speed bearings: BearingChecker accepts max. 30,000

rpm, 2,000 mm shaft diameter, and a dBi of 40. The upper

part of the table contains examples of possible combinations

of shaft diameter and rpm giving a maximum dBi of 40. The

lower part of the table exemplifies combinations that give dBi

= 0. The instrument calculates the dBi up to 40. However, it

is possible to set the dBi to max. 60 manually. A reason for

setting dBi > 40 is when measuring on e.g. turbochargers,

high-speed gearboxes etc.

Low-speed bearings: The lowest acceptable dBi is –9 dB.

However, it is nearly impossible to get a meaningful reading

from bearings in the extremely low speed ranges. The practi-

cal limit are bearings with a dBi around 0 dB (see lower half

of the table).

A heavy load with a well defined direction and a low inter-

ference level make it easier to get readings from low speed

bearings. Successful shock pulse monitoring has been carried

out on bearings with dBi = –3 (54 rpm, shaft diameter 260

mm). Note that the dynamic measuring range decreases when

dBi values get below 0. For example, a bearing with dBi = –3

showed very heavy damages at dBn = 40.

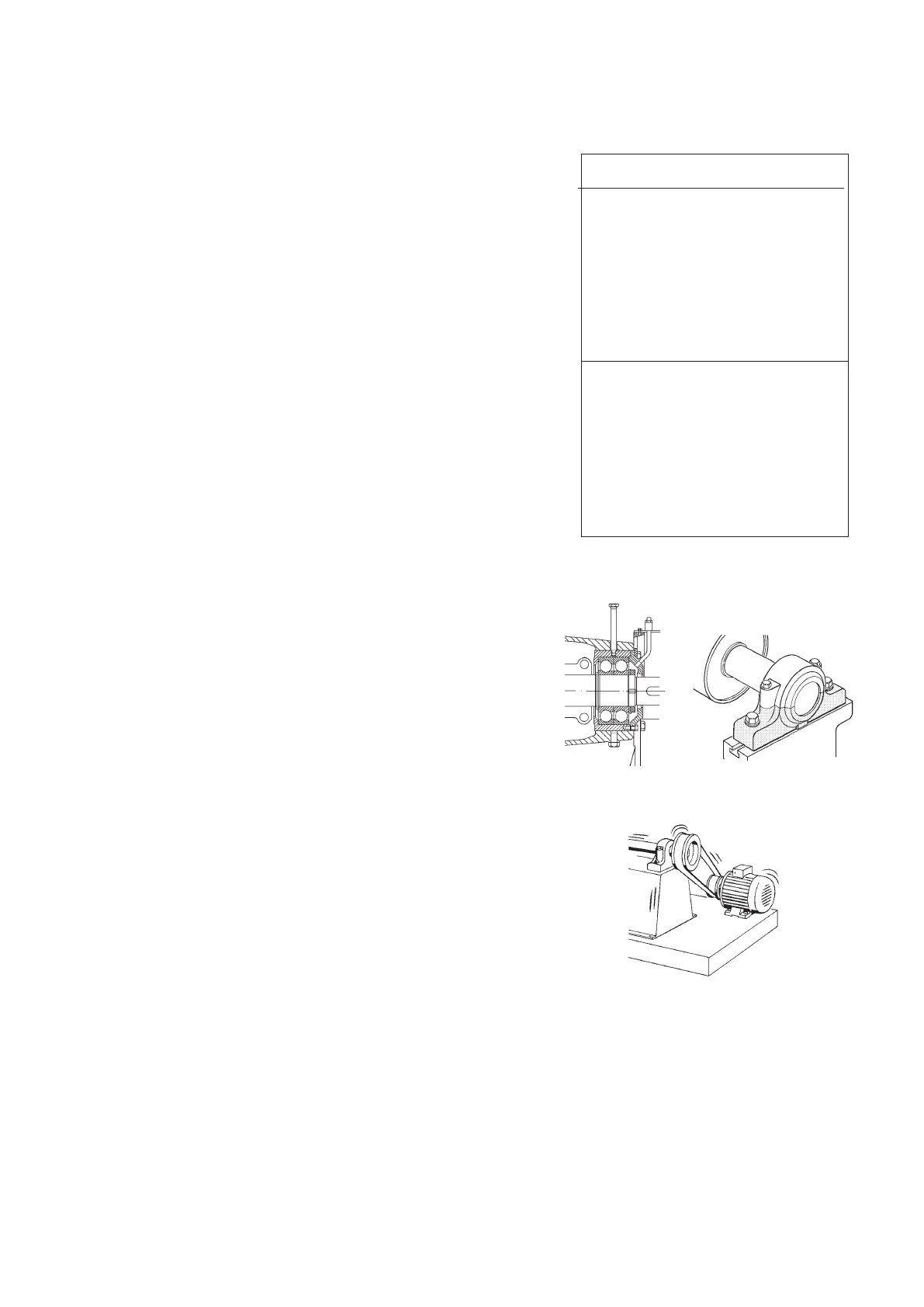

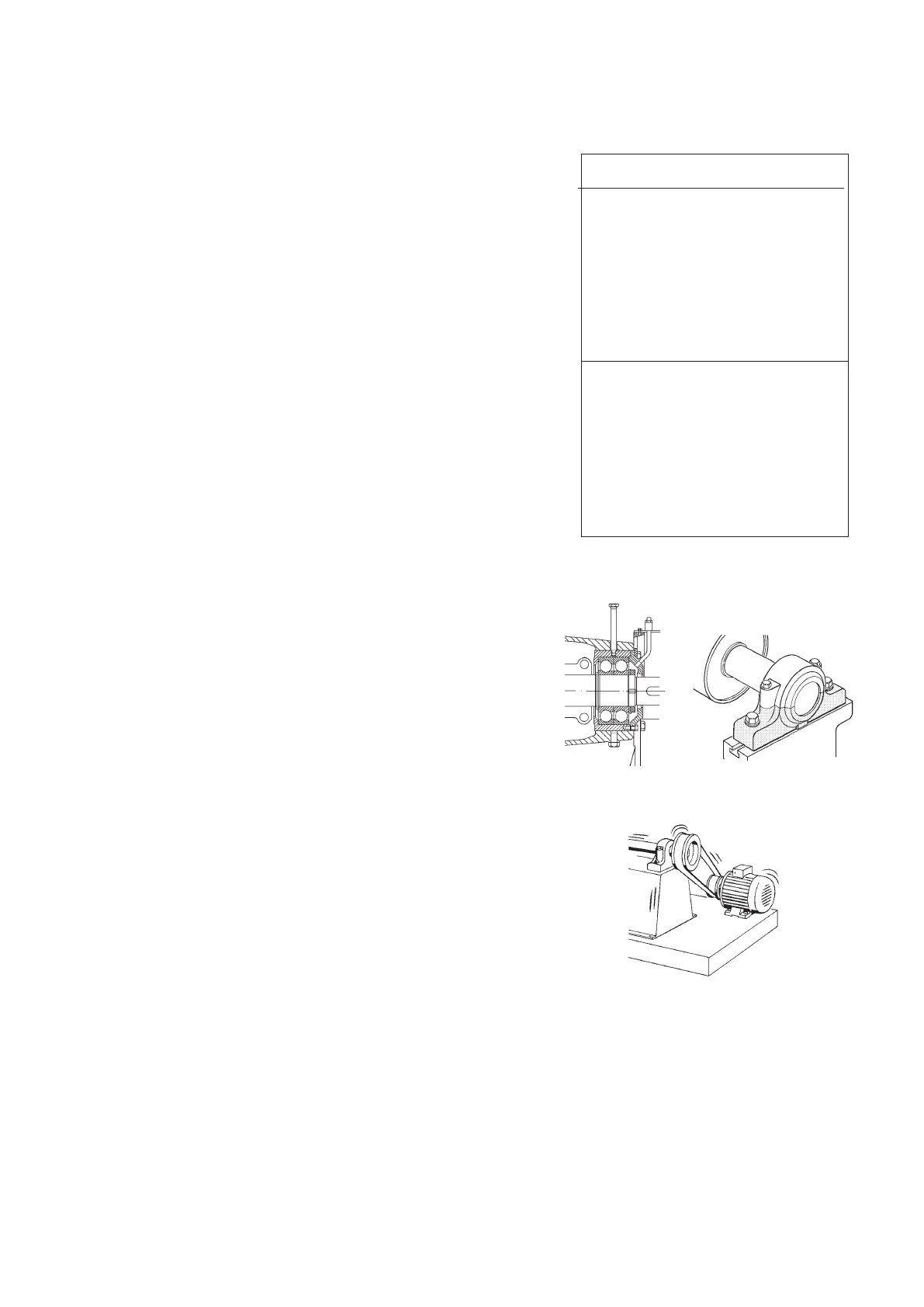

Installed adapters required: The installation of adapters is

strongly recommended for all systematic shock pulse monitor-

ing. In some cases it is a requirement:

• on bearings with dBi below 5

• on heavily vibrating bearing housings

• on covered bearing housings.

Low speed: Do not use a handheld probe on low speed

bearings. As a rule, the measurement should cover at least

10 full revolutions of the shaft. A single damaged part in the

raceway will cause a strong pulse only when hit by a rolling

element while passing through the load zone. It can take

several revolutions before that event occurs or is repeated.

Adapters required!

Covered

housing

dBi < 5

Heavy vibration

Shaft, mm rpm dBi

25 30 000 40

50 20 000 40

100 13 000 40

180 10 000 40

300 6 000 40

500 5 000 40

1 000 3 400 40

1 999 2 200 40

1 999 24 0

1 000 35 0

650 45 0

500 52 0

300 72 0

180 100 0

100 140 0

50 210 0

Measuring range

Loading...

Loading...