21

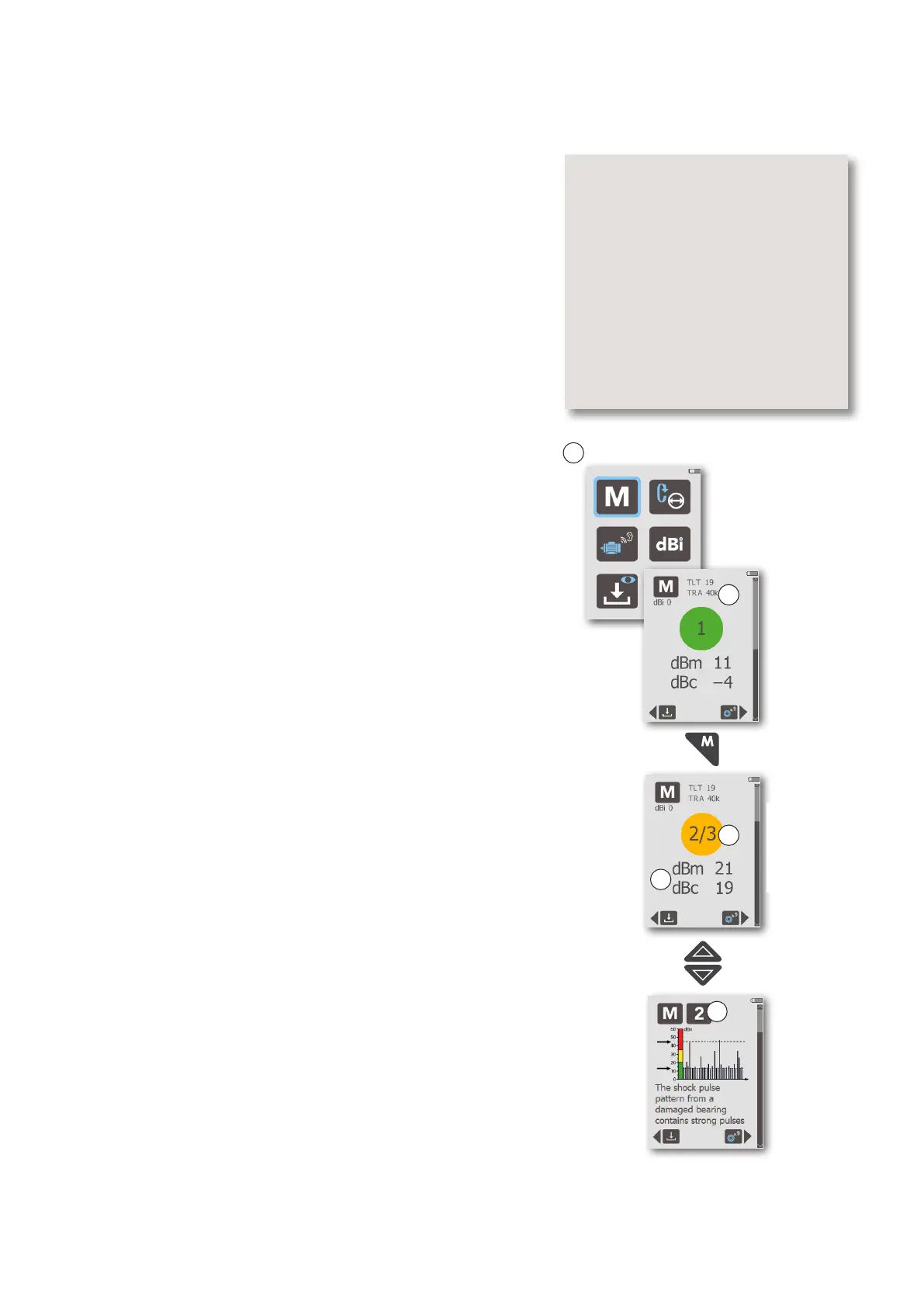

To perform a shock pulse measurement, follow these steps:

1. In the Main display (A), select the Measure icon and

press ENTER.

Before taking a measurement, make sure that the shaft

diameter and rotational speed of the bearing, or its

dBi, have been entered (se chapter “Input data”), or

the reading will be incorrect. The Measurement display

opens, showing the most recent reading (B).

2. For a new measurement, press the probe tip (or connect

the external transducer) to the measuring point, then

briefly press the MEASURE key. A single blue pixel briefly

appears at the bottom of the display, indicating that a

measurement cycle is in progress. The display backlight

is then turned off until the measurement is completed.

When the display lights up again, it shows two measure-

ment results (C): the maximum value, dBm, and the carpet

value, dBc. Depending on the dBm value, the display shows

a green, yellow or red condition indicator.

When an external transducer is used, the instrument dis-

plays a TLT warning sign if the transducer line test result is

unsatisfactory. The TLT value for the current reading is shown

at the top of the display, along with the probe/transducer

type used:

TRA INT PROBE = internal probe

TRA EXT PROBE = external probe

TRA 40K = 40000 type transducer

TRA 42K = 42000 type transducer

For further information about TLT, please see chapter “Trans-

ducer Line Test”.

3. When measurement is completed, the condition indicator

(D) shows the evaluated bearing condition (for normal-

ized readings). Press the DOWN arrow key to scroll down

to the evaluation code (E). This code (between 1 and 6)

refers to the Evaluation Flowchart on pages 34-35, which

must be used to further evaluate bearing condition.

When the instrument shows high readings (yellow or red

condition indicator), immediately verify their nature and

probable cause. Do not conclude that there is bearing dam-

age without further investigation. As first measures:

• use the headphones to identify the shock pulse pat-

tern; for more information, see chapter “Listening to

the shock pulse pattern”

• measure on and outside of the bearing housing to

identify the shock pulse source.

4. To scroll back up to the measuring result, press the UP

arrow key.

To return to the Main display from the Measurement display,

press the BACK key.

Shock pulse measurement

Check:

- Shaft diameter and rpm, dBi set-

ting

- Measuring point in the load zone

- Probe pointed straight at the

bearing

- Adapter (transducer) properly

mounted

- Adapter surface clean, undamaged

- Quick connect transducer firmly

attached

Main display

A

C

E

Measure

Scroll up/down

Condition indicators:

Red: bad (≥35)

Yellow: caution (21–34)

Green: good (≤ 20)

D

B

Loading...

Loading...