© BEKA 201 All rights reserved!6

...a product of BEKA

16

7.4.2 Function of the central lubrication pump GIGA

The central lubrication pump GIGAis designed to pump .An agitator blade forces thelubricants up to NLGI category 2

lubricant through a grease strainer to the suction chamber of the pump element. The is by anpump element driven

eccentric so that the .function is ensured even at low temperatures

The central lubrication pump has .Aseparate lubrication circuit can be connected at each outlet. For eachmax. 3 outlets

outlet, a pump element is required. The on the installed (see 7.3 Pumpdelivery volume depends pump element

element). Unused outlets must be sealed with a screwed sealing plug (see 15. List of spare parts).

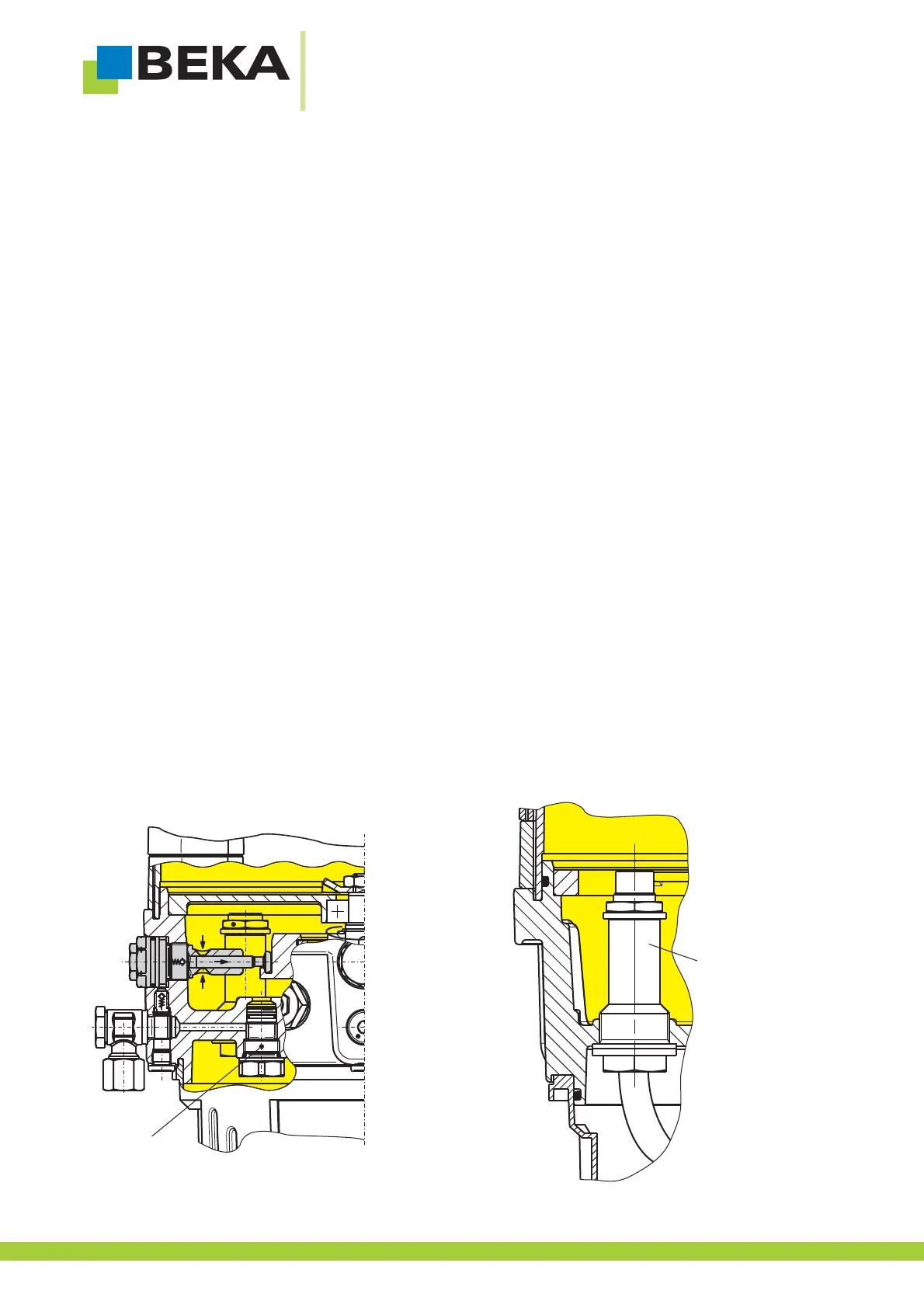

The central lubrication pump can be equipped with an device for the (Fig. 6).integrated level monitoring min. fill level

This transmits a steady signal. If the fill level falls , the level switch stops the signal. Anbelow a certain level external

signal transmitter switch off the central lubrication pumpshould to prevent air being pump into the system.

7.4.3 Function of the central lubrication pump GIGAPLUS

The central lubrication pump GIGA PLUS is designed to pump . An agitator bladelubricants up to NLGI category 2

forces the lubricant through a grease strainer to the suction chamber of the pump element. The ispump element driven

by an eccentric so that the .function is ensured even at low temperatures

The central lubrication pump has .Aseparate lubrication circuit can be connected at each outlet. For eachmax. 3 outlets

outlet, a pump element is required (see 7.3. Pump element).The can be varieddelivery volume by combining the

outlets (see 8.3 Combining the outlets). The delivery volume from one or more pump elements can be discharged at any

outlet. Unused outlets must be sealed with a screwed sealing plug (see 15. List of spare parts).

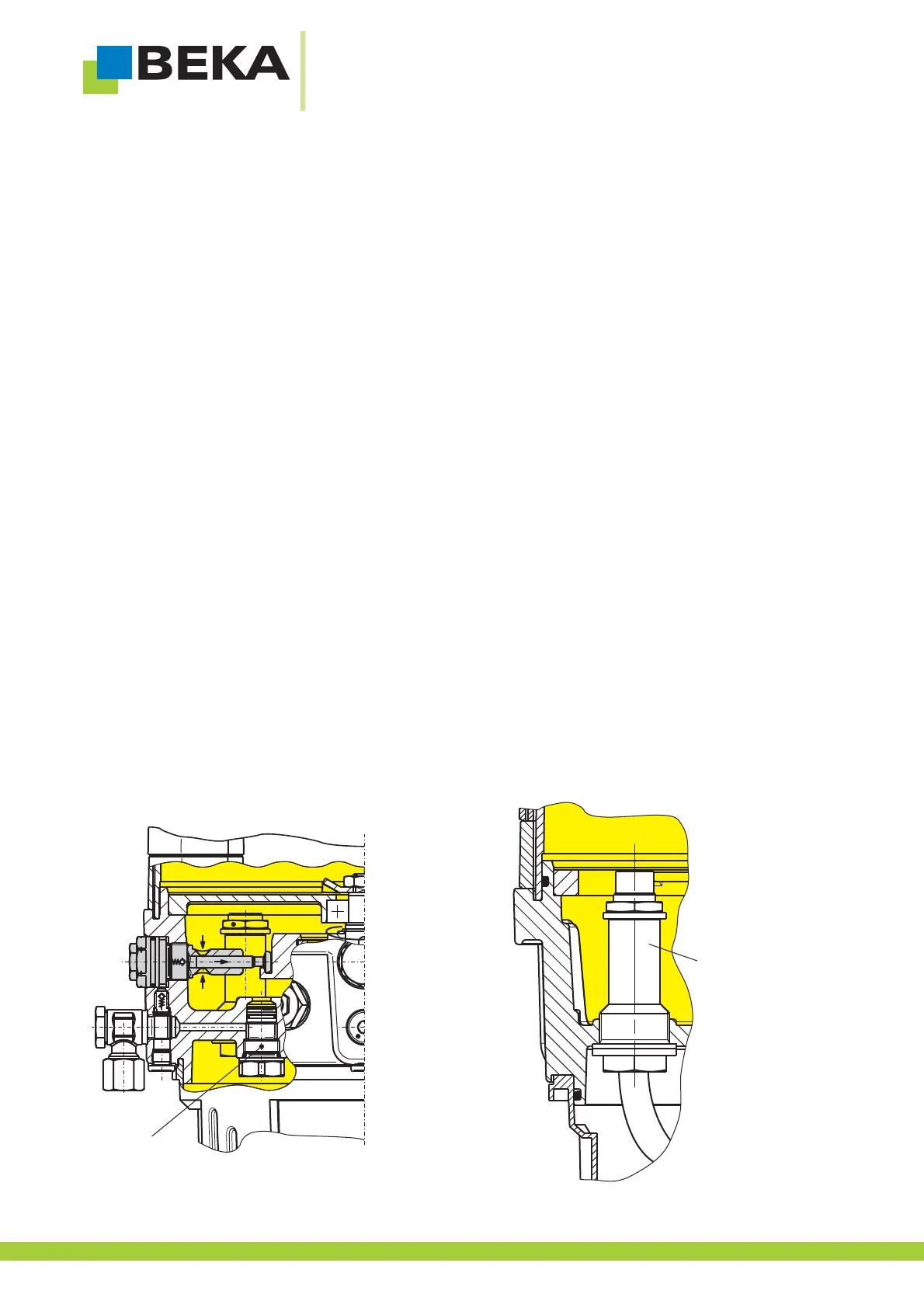

A ( ig. 11) or an integratedpressure limiting valve (version ball valve) installed at the pump element pressureF

limiting valve (version ball valve) limits the pressure in case of an error ( ig. 5).F

The pump can be equipped with an for the (Fig. 6). If the fill levelintegrated level monitoring device min. fill level falls

below a certain level external signal transmitter central, the level switch stops the signal. An should switch off the

lubrication pump to prevent air being pump into the system.

Fig. 5: Fig. 6:

Pressure limit valve integrated in the Level switch integrated in the reservoir

central lubrication pump

Pressure limit

valve (version

ball valve), internal (optional)

Level switch

(optional)

Loading...

Loading...