CHAPTER 8. MAINTENANCE SCHEDULES

Preventative maintenance is very important. It includes lubrication, checks and adjustments which the operator

can perform. Procedures which require

BELL EQUIPMENT

Product Support to perform are noted in the in-

structions.

Most of these service measures are simple to carry out and do not need any detailed explanation. The instruc-

tions which require specific procedures are detailed in this Chapter.

Note: The 100 hour service is done by

BELL EQUIPMENT

Product Support.

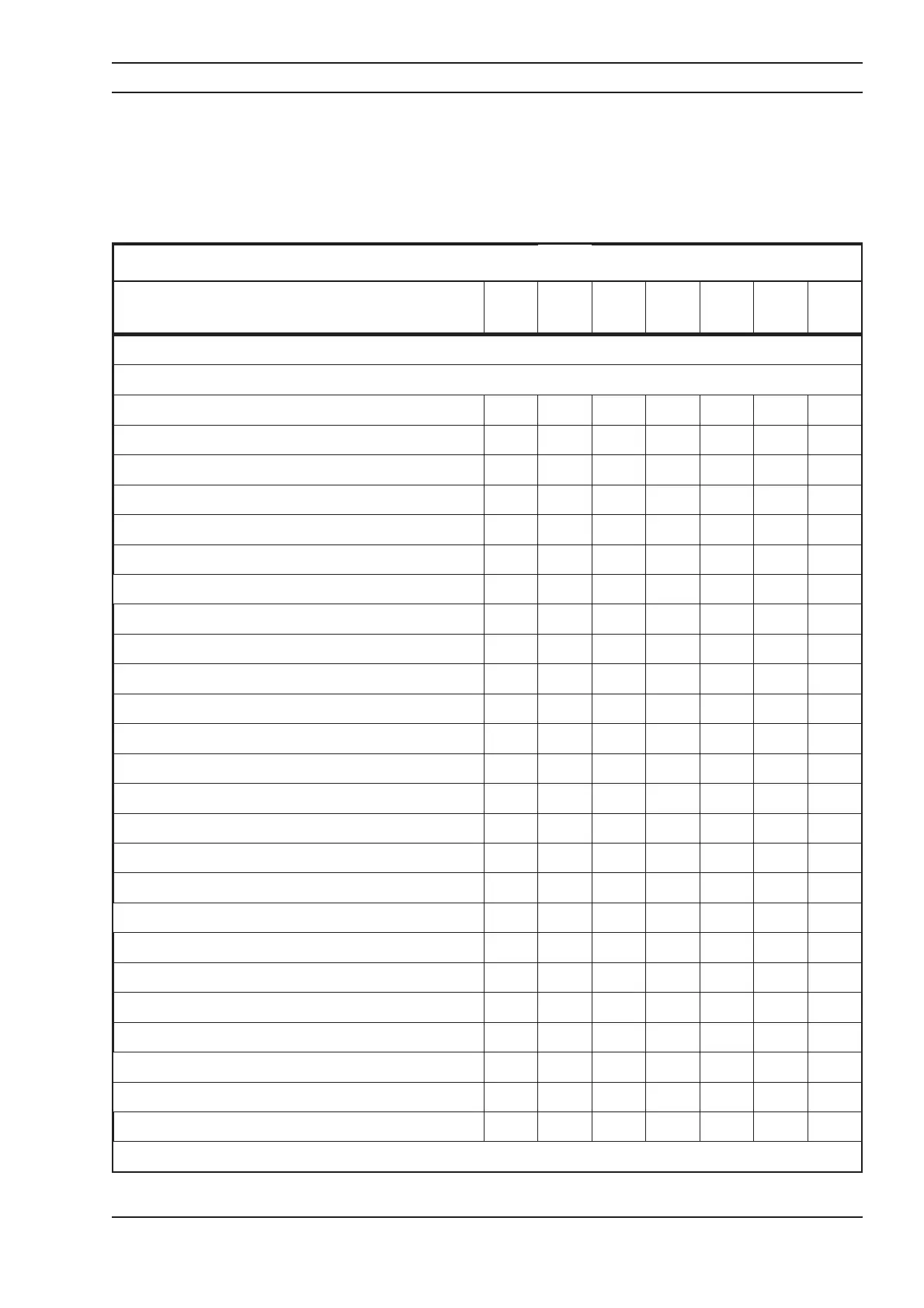

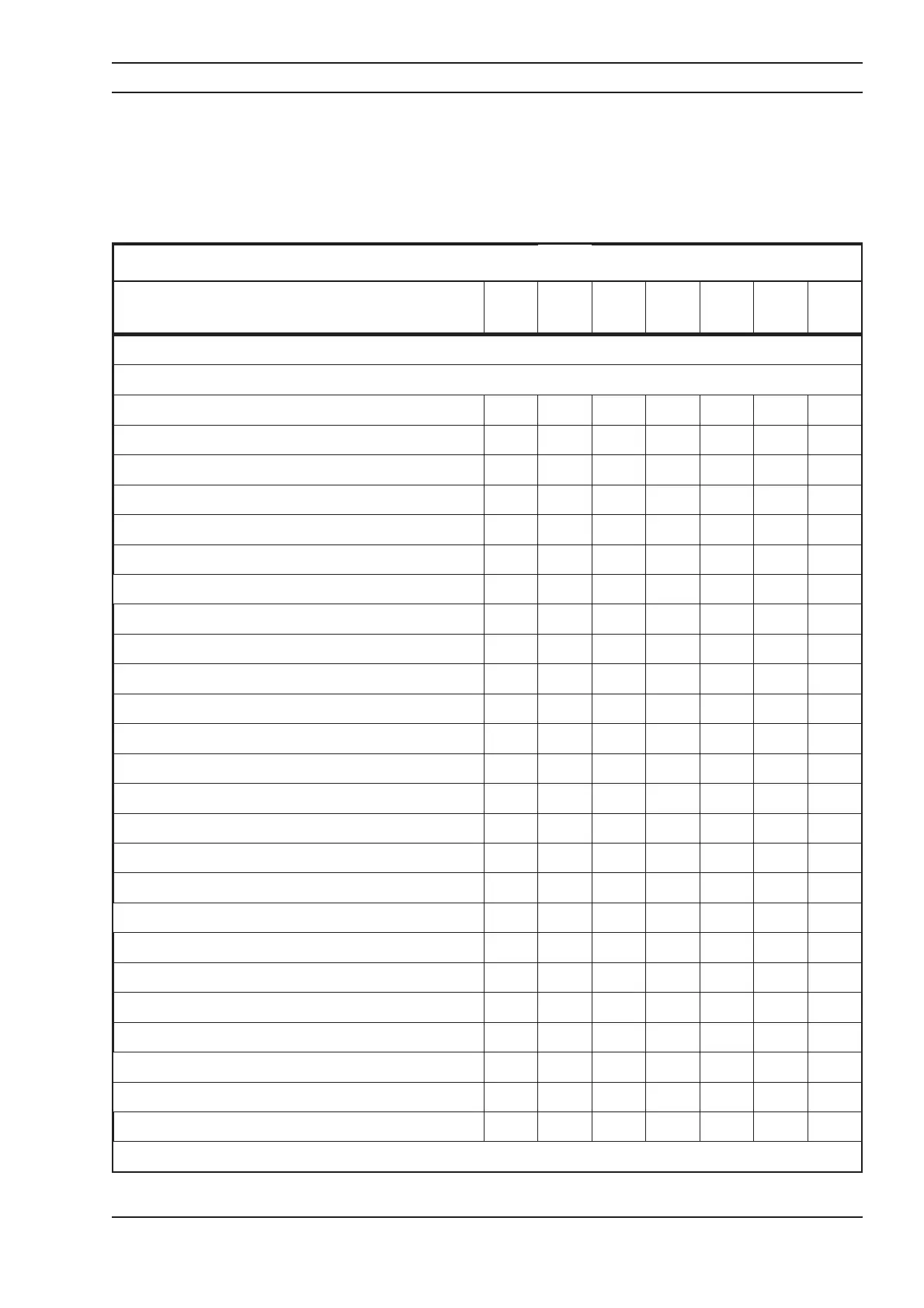

Maintenance Schedule in Running Hours

Details Daily 1st

100

Every

250

Every

500

Every

1 000

Every

2 000

As

Req.

ENGINE

Note: For further maintenance and service procedures, refer to the ADE Engine Repair Manual 442 Series

Check the oil level X

Check and clean the oil filler cap and seal X

Check and clean the crankcase breather X

Drain the primary fuel filter X

Check the coolant level X

Change the oil and oil filters X X

Clean the fuel screen X X

Change the fuel filters X X

Check the anti freeze/corrosion inhibitors X X

Adjust the valve clearance X X

Adjust the drive belts tensioning X X

Change the drive belts X

Flush and renew the coolant X

Change the crankcase breather 4 000

Service the injectors 1 200

Change the injectors 2 400

Service and calibrate the injector pump 3 600

Check the engine compartment components X

Check for oil and fuel leaks X

Check all hoses and clamps X

Check all electrical connections X

Check the rubber mountings and mounting bolts X

Check the cooling pack X

Clean the cooling pack X

Check the fan cowling X

870984-01 55

June 1, 1999

Loading...

Loading...