37

• Always call local service representative if electrical

problems develop.

• Always replace ALL FAULTY PARTS before lift is put

back into operation.

• Daily: Make a visual inspection of ALL MOVING

PARTS and check for excessive signs of wear.

• Daily: Check safety locks to ensure they are in good

operating condition.

• Daily: Check cables and sheaves for wear. Replace

worn parts as required with genuine BendPak parts.

• Daily: Inspect adapters for damage or excessive

wear. Replace as required with genuine BendPak

parts.

• Weekly: Lubricate all sheave and rollers with general

purpose oil.

• Weekly: Check all cable connections, bolts and pins

to insure proper mounting.

• Monthly: Check equalizer cable tension. Adjust per lift

installation instructions.

• Monthly: Lubricate locking latch shafts. Push latch

handle several times for oil to penetrate pivot points.

• Every 3 Months: Check anchor bolt torque. Anchors

should be torqued to 90 ft/lbs.

• Semi-Annually: Check uid level of lift power unit and

re ll if required per lift installation instructions.

• Replace all caution, warning or safety related decals

on the lift if unable to read or missing. Reorder labels

from BendPak.

• Refer to ANSI/ALI ALOIM booklet for periodic

inspection checklist and maintenance log sheet.

LIFT OPERATION SAFETY (CONT’D)

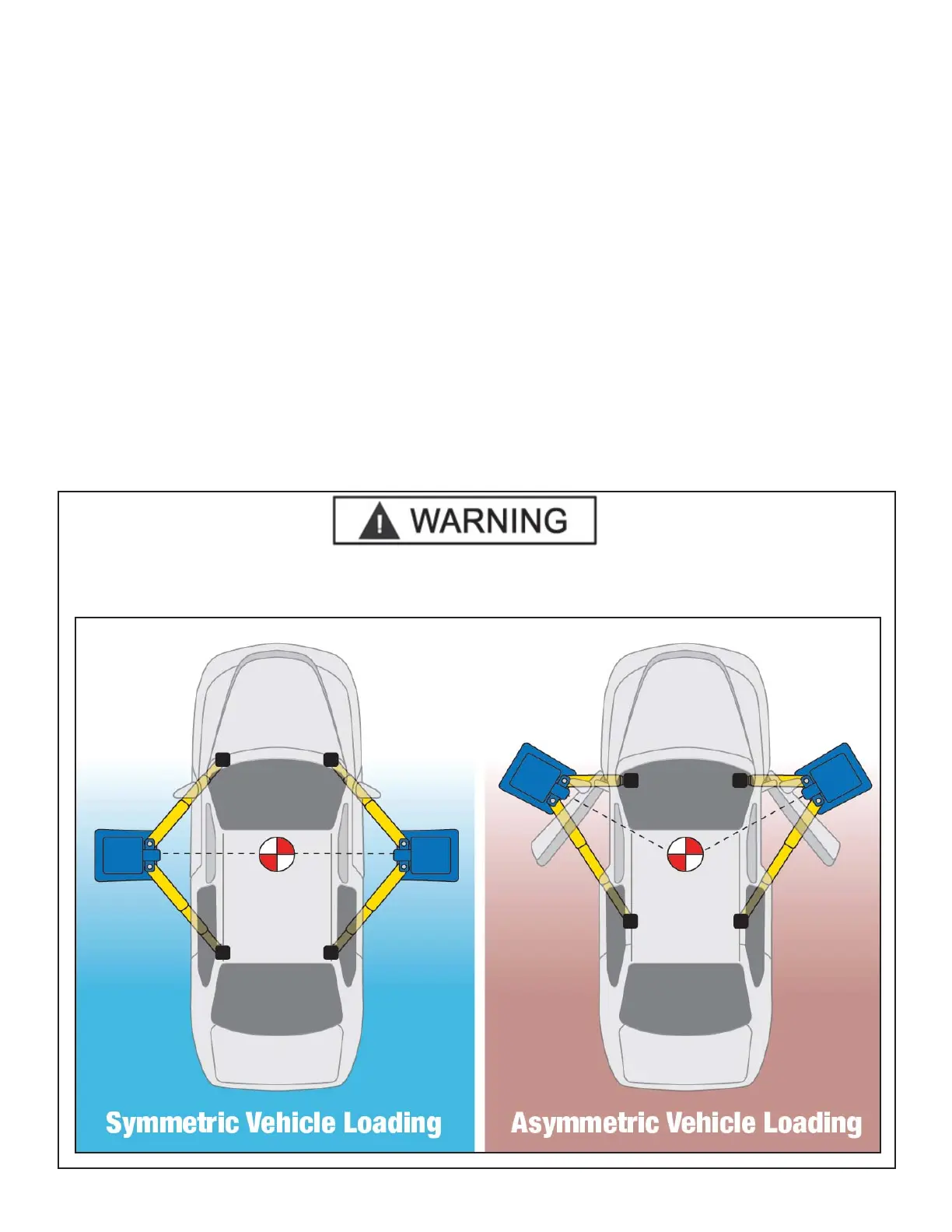

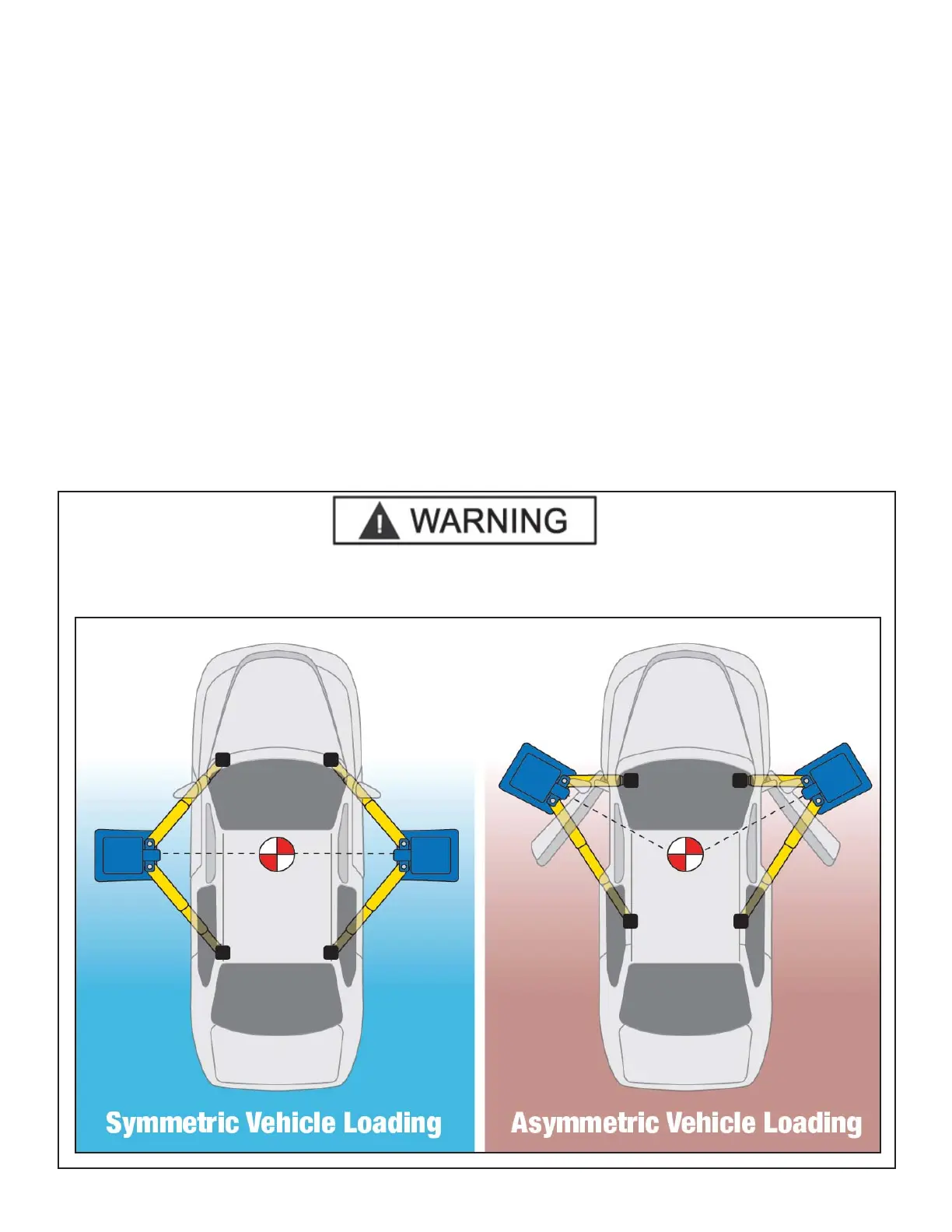

Make sure vehicle is neither front nor rear heavy and select the proper con guration for the vehicle to be

lifted (symmetric/asymmetric) as shown below. Center of balance should be midway between adapters.

Loading...

Loading...