2929

STEP 15

(Power Unit Connection)

1. Have a certi ed electrician run the power supply to

motor. Refer to the data plate found on the motor for

proper power supply and wire size.

RISK OF EXPLOSION!

This equipment has internal arcing or parts that may spark

and should not be exposed to ammable vapors. Motor

should not be located in a recessed area or below oor

level. NEVER expose motor to rain or other damp

environments. DAMAGE TO MOTOR CAUSED BY

WATER IS NOT COVERED UNDER WARRANTY.

STEP 16

(Lift Start Up / Final Adjustments)

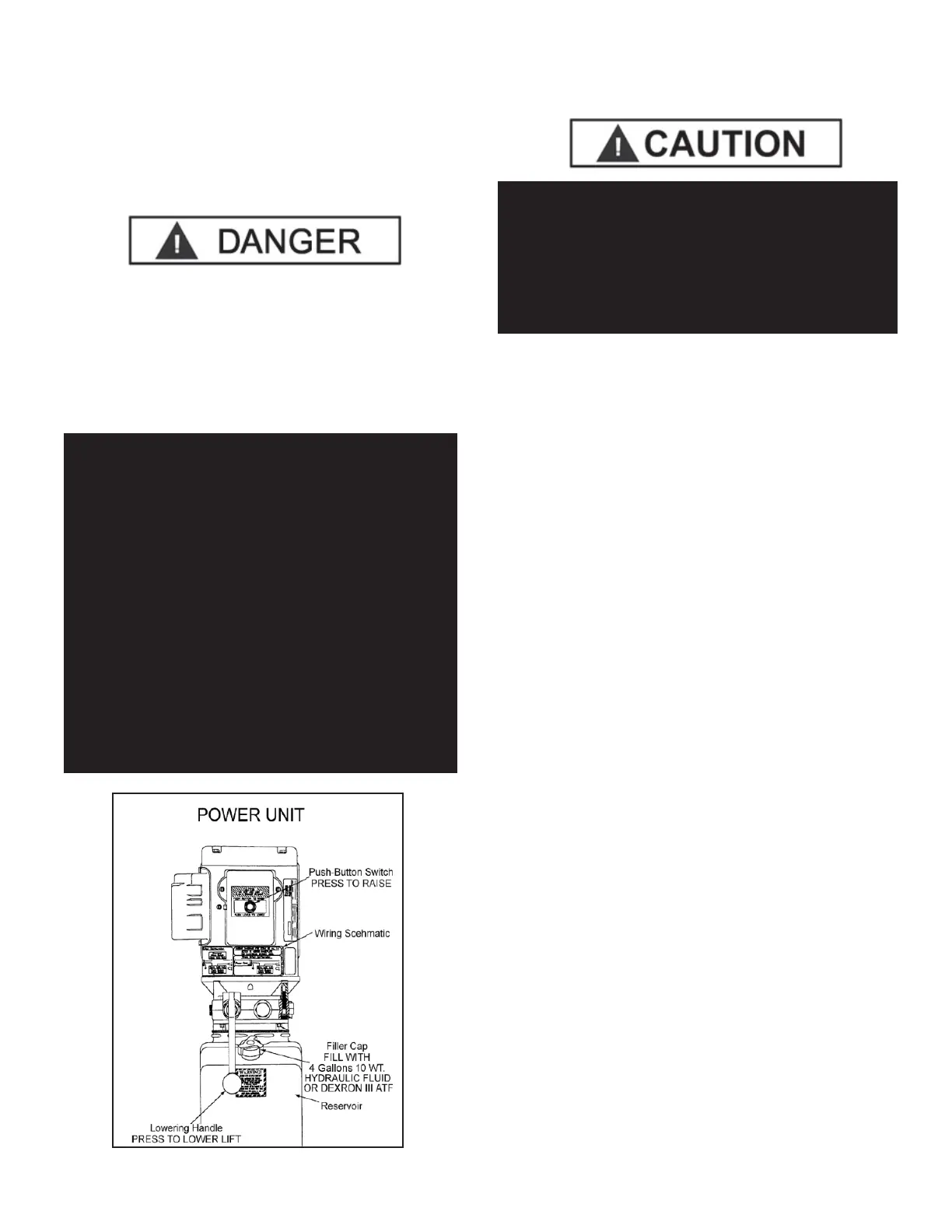

1. Make sure the power unit reservoir is full with four

(4) gallons of 10-WT hydraulic oil or Dexron-III automatic

transmission uid.

2. Apply light axle grease to the inside of the posts where

the slide blocks glide.

3. Test the power unit by pressing the push-button

switch. If the motor sounds like it is operating properly,

raise the lift and check all hose connections for leaks. If

the motor gets hot or sounds peculiar, stop and check all

electrical connections.

4. Before proceeding, double-check to make sure all

cables are properly positioned within the grooves of ALL

sheaves. Make sure all cable sheave retaining pins and/or

clips are secure.

5. Check to make sure that all safety locks are cleared and

free.

6. Continue to press the button to raise lift until the

cables get taut and the lift starts to move.

7. KEEP HANDS AND FEET CLEAR. Remove hands and

feet from any moving parts. Keep feet clear of lift when

lowering. Avoid pinch points.

8. Check all MAIN SAFETY LOCKS to make sure they

move freely and spring back to the lock position when

released. Lubricate all SAFETY PIVOT points with light

spray-oil.

9. Cycle the lift up and down a few times to ensure that

the safety locks are engaging uniformly and that the safety

release mechanisms are functioning. Re-adjust if

necessary.

NOTE:

CAUTION NEVER OPERATE THE MOTOR ON LINE

VOLTAGE LESS THAN 208V. MOTOR DAMAGE

MAY OCCUR WHICH IS NOT COVERED UNDER

WARRANTY. HAVE A CERTIFIED ELECTRICIAN

RUN APPROPRIATE POWER SUPPLY TO MOTOR.

SIZE WIRE FOR 25 AMP CIRCUIT. SEE MOTOR

OPERATING DATA TABLE. USE SEPARATE CIRCUIT

FOR EACH POWER UNIT. PROTECT EACH CIRCUIT

WITH TIME DELAY FUSE OR CIRCUITBREAKER.

FOR SINGLE PHASE 208-230V, USE 25 AMP FUSE.

THREE PHASE 208-240V, USE 25 AMP FUSE. FOR

THREE PHASE 400V AND ABOVE, USE 15 AMP

FUSE. ALL WIRING MUST COMPLY WITH NECK AND

ALL LOCAL ELECTRICAL CODES.

Fig 15.1

CAUTION!

DURING THE START-UP PROCEDURE, OBSERVE

ALL OPERATING COMPONENTS AND CHECK

FOR PROPER INSTALLATION AND ADJUSTMENT.

DO NOT ATTEMPT TO RAISE VEHICLE UNTIL A

THOROUGH OPERATIONAL CHECK HAS BEEN

COMPLETED.

Loading...

Loading...