50

172 305 25 05-01

1(3)

GENERAL INSTRUCTION

Flame monitoring and measurement of ionisation current

The burner is monitored according to the ionisation principle. Check the

ionisation current on start-up and on each service call.

The reason for a low ionisation current may be leaking currents, bad

connection to earth, dirt or a faulty position of the flame electrode in the

burner head. Sometimes also a faulty gas/air mixture may cause too weak

a ionisation current.

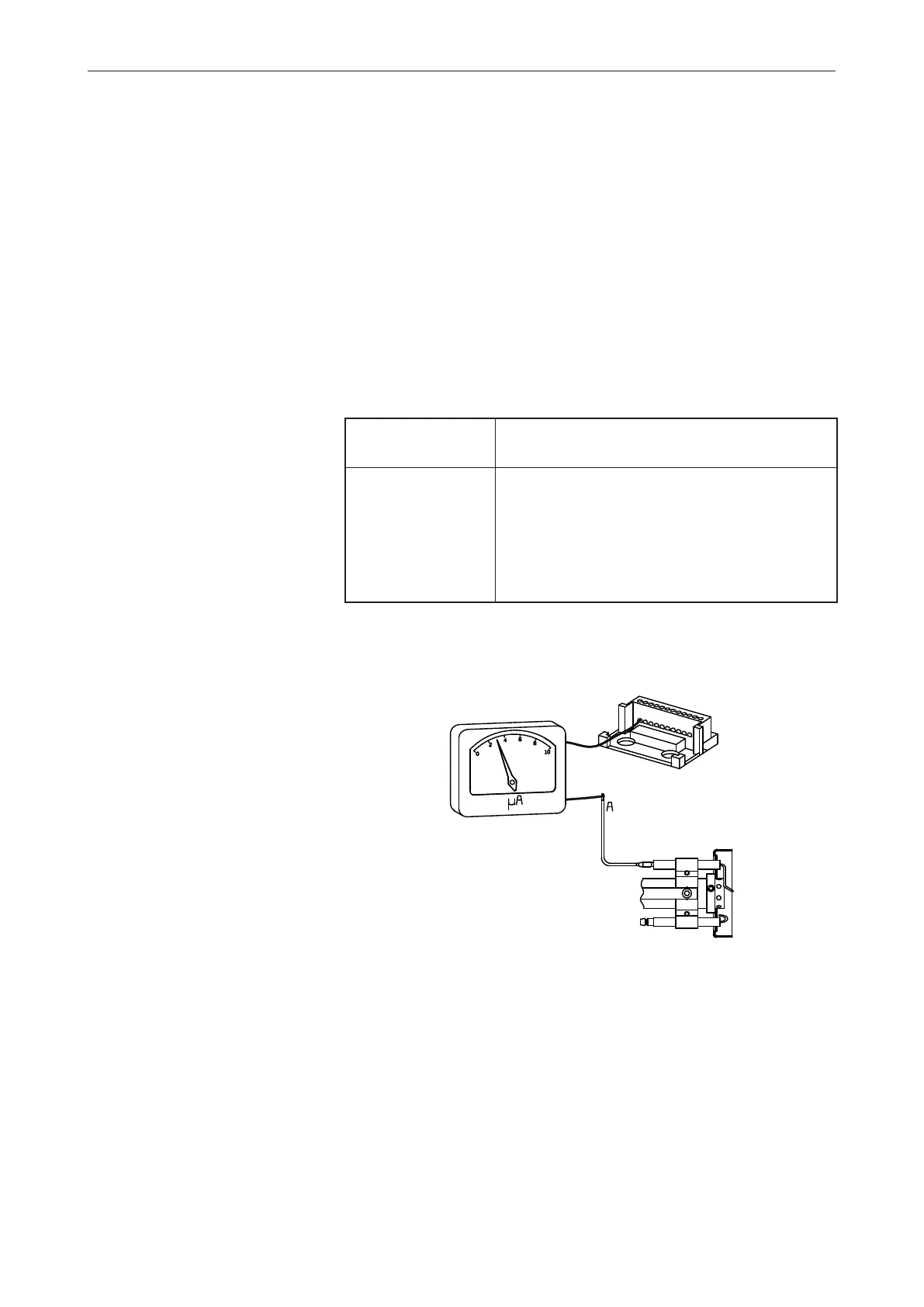

The ionisation current is measured by means of a microampere meter

(μA) connected in series with the flame electrode and the gas burner

control.

Connect the μA-meter, see figure. Min. required ionisation current according

to table. In practice this current must be considerably higher, preferably

more than 10 μA. All the gas burners are equipped with a ionisation cable

that can be slit which facilitates the connection of the μA-device.

Flame monitoring

Gas control Connection to terminal Min. ionisation

in gas control current required

LMG Serie A 1 2 μ A

LMG Serie B 2 10 μA

LGB 1 10 μ A

LFL 24 10 μ A

MMI 810 2 5 μ A

TMG 740-3 1 5 μ A

Loading...

Loading...