22

Bentone BFG 1

Z

Y

6. Settings

6.1 Brake plate adjustment

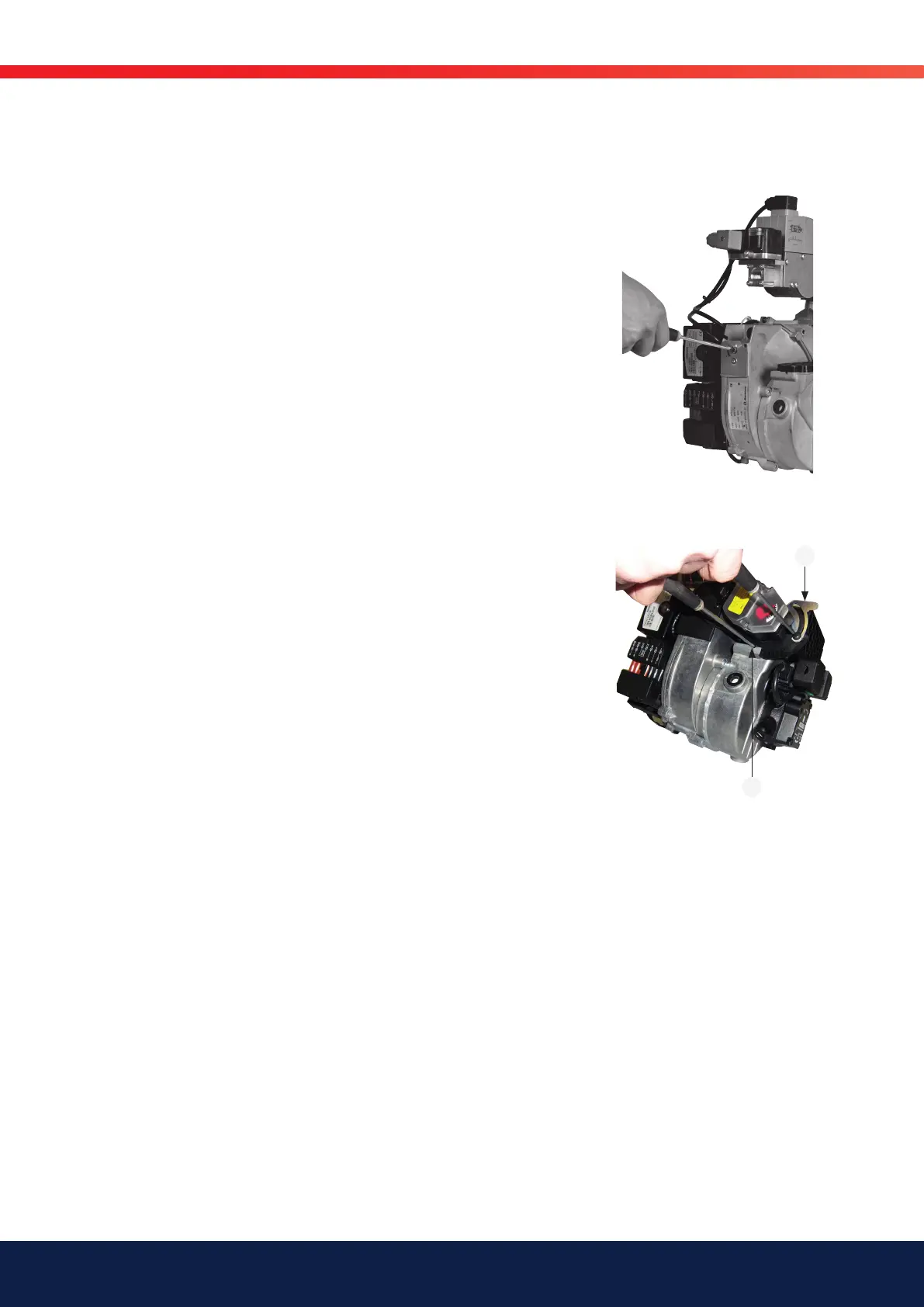

The burner is equipped with a control which changes the position of the brake

plate in the blast tube. This is used to set the correct pressure differential across

the combustion device and thereby get a good combustion without pulsations.

The setting to be used depends on the set effect and the overpressure in the

boiler. (For basic setting, see Technical data).

Brake plate settings

• Smaller gap: turn the screw to the right

• Larger gap: turn the screw to the left

The setting of the brake plate position affects the air ow. Therefore, the air

must always be readjusted with the air regulation device of the burner.

6.2 Air adjustment

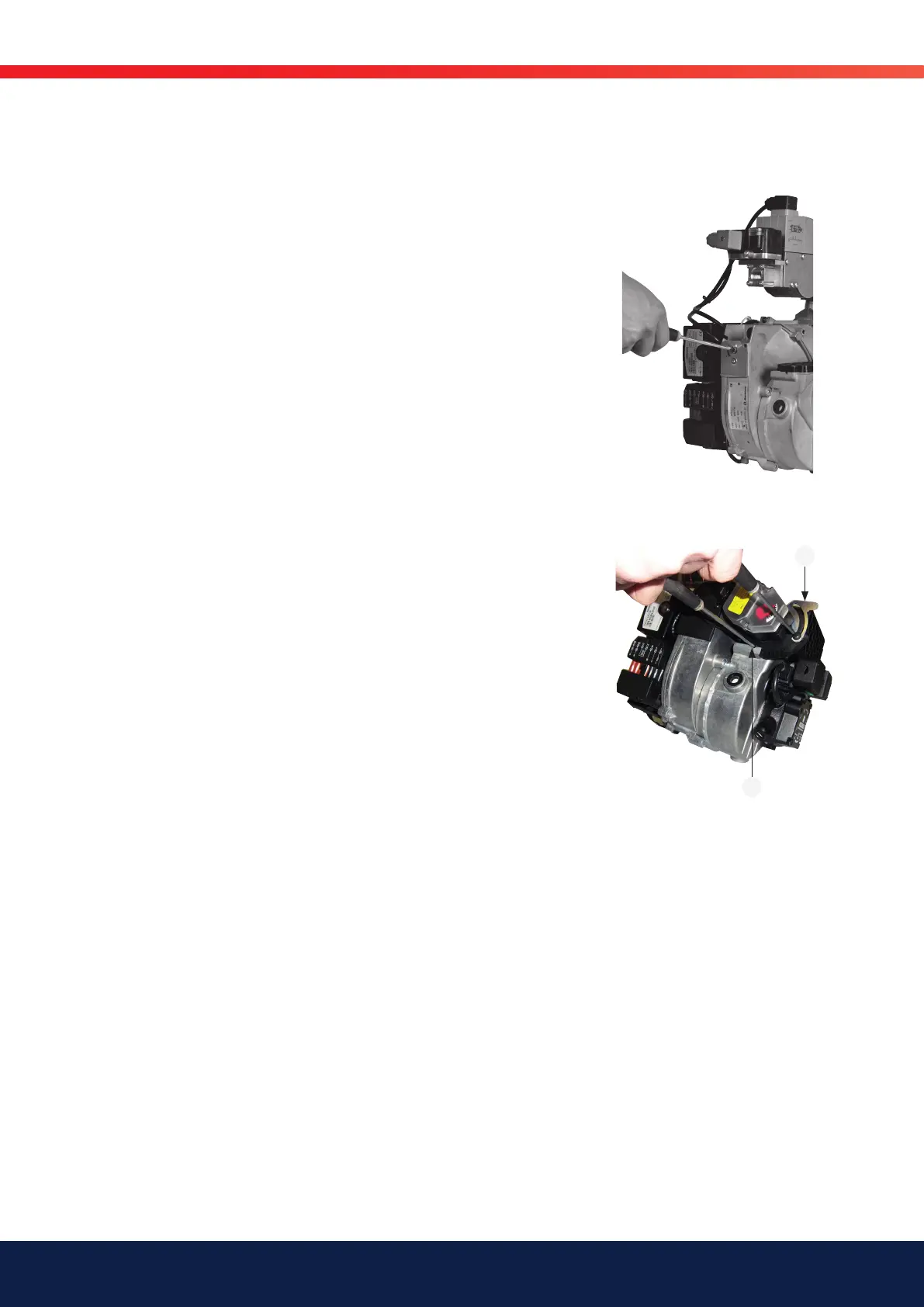

For two-stage burners, the amount of air is set in two different positions.

When performing adjustments, the maximum load must always be adjusted

rst. This is because adjusting the air damper for the maximum load may

affect the air quantity for the minimum load. The maximum load is adjusted

by turning the air regulator (Y). The air setting at maximum load will then

operate so that when the boiler is calling for the maximum load, the damper

motor opens completely and the amount of air for combustion is controlled

by the air regulator (Y). Minimum load is set by loosening the screw (X) and

adjusting the control plate (Z) for the damper powered by the damper motor.

6.2.1 Air volume

The air volume setting for the maximum load is adjusted by turning screw (Y)

with an allen key. How open the damper must be is determined by the heat

output and overpressure in the boiler as well as other settings on the burner

such as the position of the brake plate. To adjust the burner as quickly and as

easily as possible, adjustments should always start with the maximum load,

as adjustments here also affect the minimum load.

Set the minimum load by adjusting the control plate (Z). By changing settings

on the control plate towards the higher values on the scale, the opening

of the damper powered by the damper motor increases, thus increasing

the amount of air for the combustion process. To reduce the amount of

air, perform the opposite adjustment. When adjusting the minimum load,

you should always make sure that the damper for maximum load is open

far enough so that it has no signicant effect on the amount of air for the

minimum load. The adjustment should be performed alternately: rst

adjustment of the minimum load followed by adjustment of the maximum

load and then repeat the procedure unless acceptable combustion is

achieved.

172 525 46-3

Loading...

Loading...