2. Installation

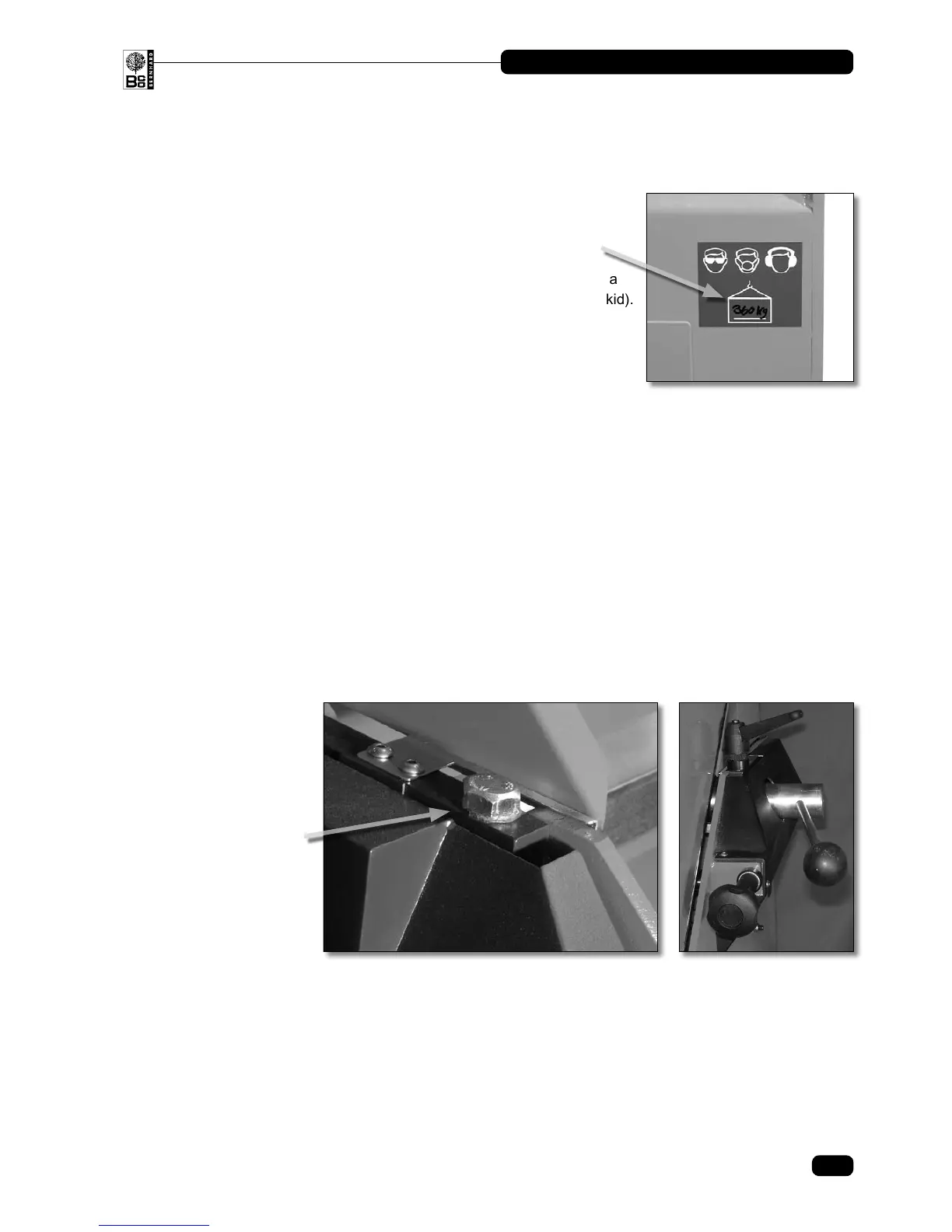

Hex head

bolt

2.2 Location

The machine should be installed in a well-lit area, set up on a solid oor base of concrete

or similar. Wooden oors should ideally be avoided.

Using a spirit level, laid across / along the traverse rails, the machine can be leveled easily,

suitable metal packing may be placed under the cabinet chassis feet.

2.1 Handling

The weight of the machine is indicated on the plate on

the front of the machine.

If the machine is supplied crated, it can be moved by a

suitable forklift or pallet truck under the crate base (skid).

Once the lid and sides of the crate have been removed,

the machine remains bolted to the base (skid).

LIFTING WITH CHAINS/STRAPS/FORKS MUST ONLY

BE CARRIED OUT AS INDICATED BY LABELS ON

THE MACHINE NOT BY MEANS OF THE TRAVERSE GUIDE RAILS.

2.3 For transit purposes, the blade-mounting bar is locked in position at both ends. Some units

may be shipped with a hex head bolt in the right hand clamp. If so, the clamp lock down

lever is in the tool drawer of the machine cabinet. Remove replace the hex head bolt with

the lever and tighten down.

The hex head bolt on the left-hand clamp should be eased off and adjusted to permit

rotation of the mounting bar with a small amount of resistance.

Do not release the right hand clamp (lock down lever) until the weight has been taken on

the angle control lever. For all subsequent use only the lock down lever will be used to hold

the mounting bar in position. If the lock down lever does not appear to be applying enough

force, the hex head bolt on the left-hand needs to be a little tighter.

7

ANGLEMASTER • AM3000

© Bernhard and Company Limited

Loading...

Loading...