64

BIFFI FAIL SAFE ELECTRIC ACTUATORS, MODEL EFS2000V4

InstructIon and operatIng Manual

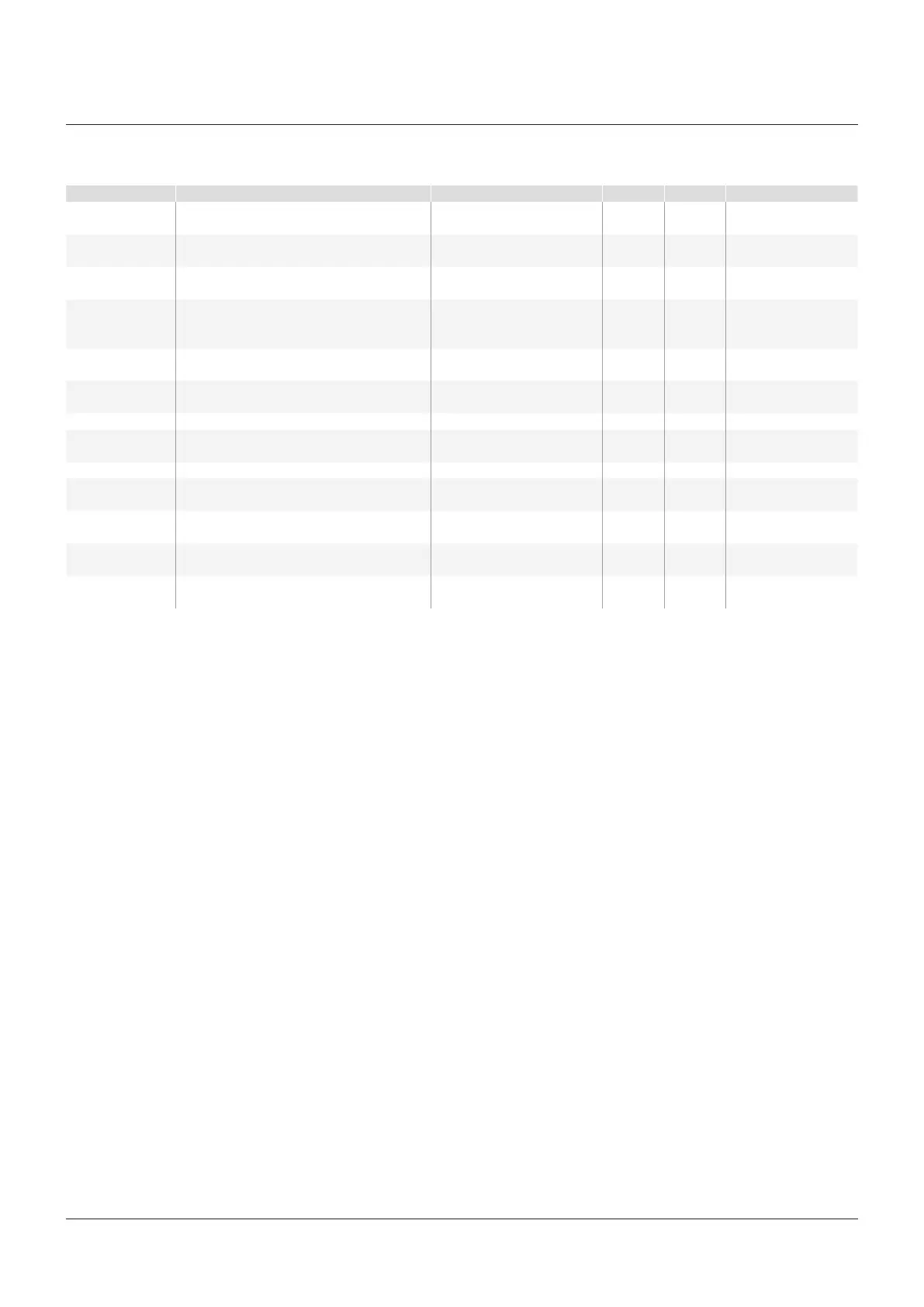

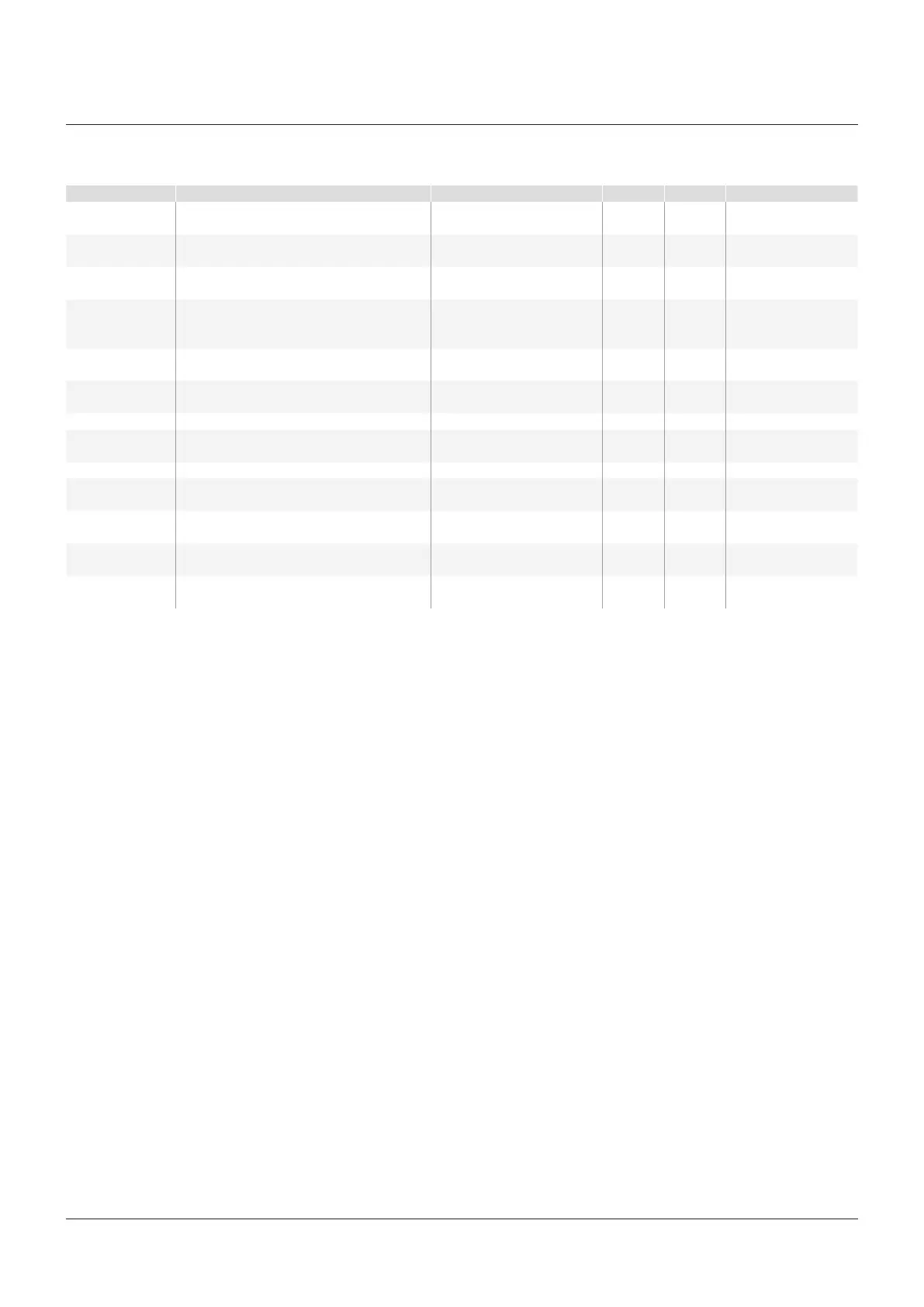

17.5.12 Warning table

Configuration object nr.: Number indicates the number of the parameters to be configured. To clear the alarm the table of all ICON2000

parameters is necessary. Please contact Biffi after sales service to solve the problem.

If the alarm message is ‘CONFIGURATION OBJ 9999’ only one of the ICON2000 parameters needs to be changed. For

instance: enter the SET-UP menu, actuator set-up, torque set-up, and either increase or decrease the closing torque

by1%. As the alarm message disappears re-enter the SET-UP menu, actuator set-up, torque set-up, and set the

previous value (see paragraph 9.1.2. of document BIFRM-0003-EN: ‘Set-up routines, actuator set-up, torque set-up’).

Hardware nr.: Number indicates the module that is not working. The problem may be due to a malfunction of the module, to an

incorrect wiring between modules, or to an incorrect configuration of the ICON2000. Please contact Biffi after sales

service to solve the problem. The following hardware alarms can be detected:

• Hardware 1 = incorrect coding of local push buttons and selector

• Hardware 2 = incorrect configuration of Ain/Aout optional module

• Hardware 3 = no communication between Ain/Aout optional module and base card

• Hardware 4 = incorrect configuration of type of terminal board

• Hardware 5 = no communication between terminal board and base card

• Hardware 6 = incorrect configuration ICON2000/F01-2000

• Hardware 7 = incorrect configuration of type of bus card

• Hardware 8 = no communication between bus card and base card

• Hardware 9 = EFS clutch card failure

• Hardware 10= no communication between EFS clutch card and base card

Display message Condition for warning Action Local Remote Warning reset

High torque in OP

(near max)

Measured torque 10% lower than the relevant value

configured in torque set-up or stroke limits routine

Check the torque necessary to

move the valve

Available Available Close, control

High torque in CL

(near max)

Measured torque 10% lower than the relevant value

configured in torque set-up or stroke limits routine

Check the torque necessary to

move the valve

Available Available Open, control

Internal temperature

(nearlimits)

Temperature inside the actuator enclosure higher

than 80°C or lower than -35°C

Find the heat source and insulate

the actuator

Available Available Control temperature

>-35°C or <80°C

Main voltage (near

limits)

Value of the main voltage out of the correct range

(-15% or +10% of the value stated in the nameplate

menu) or wrong frequency

Check section of wires and values

of voltage and frequency

Available Available Main voltage correct

(Max) contactor

cycles

Maximum number of contactor cycles reached Change contactor and reset

operation log

Available Available Clear recent data log

Maintenance request Date of the next maintenance reached Perform maintenance and set next

maintenance date

Available Available Change date

Motor current Motor current higher or lower than limits Check electrical motor Available Available Current okay

Wrong stroke limits The routine that monitors the stroke limits detects a

wrong end of travel condition

Recalibrate both stroke limits Available Available Recalibrate both stroke

limits

Bus Fieldbus not working Check bus communication Available Available Bus okay

PST PST cycle aborted Check if condition to abort has

happened

Available Available New PST cycle or by local

operator interface

T-PST T-PST value failed Check baseline values and

parameter T-PST

Available Available new PST cycle or by local

Operator interface

T-RET T-RET value failed Check baseline values and

parameter T-RET

Available Available New PST cycle or by local

operator interface

OV-TR OV-TR value failed Check PST travel and parameter

OV-TR

Available Available New PST cycle or by local

operator interface

Loading...

Loading...