63

BIFFI FAIL SAFE ELECTRIC ACTUATORS, MODEL EFS2000V4

InstructIon and operatIng Manual

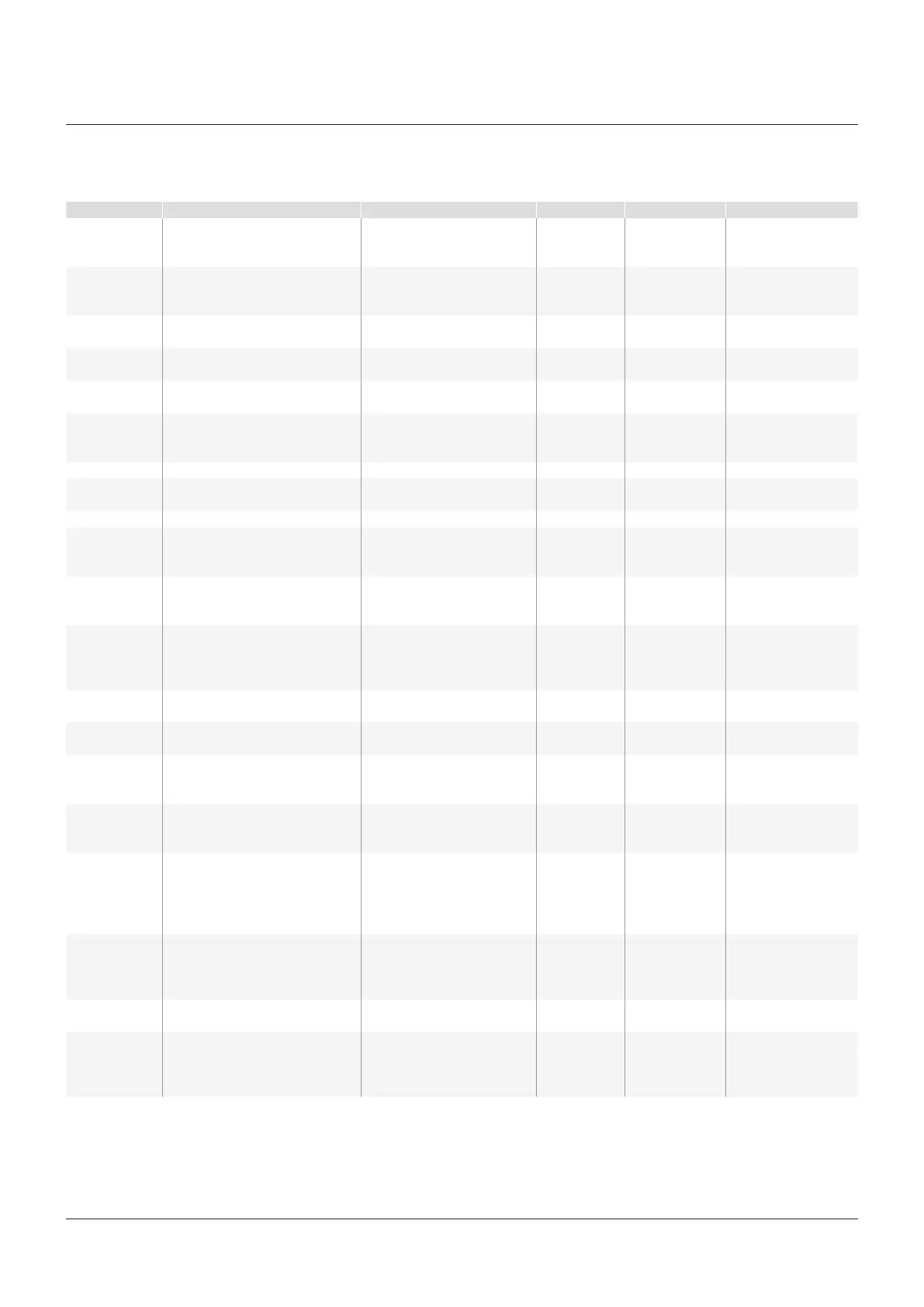

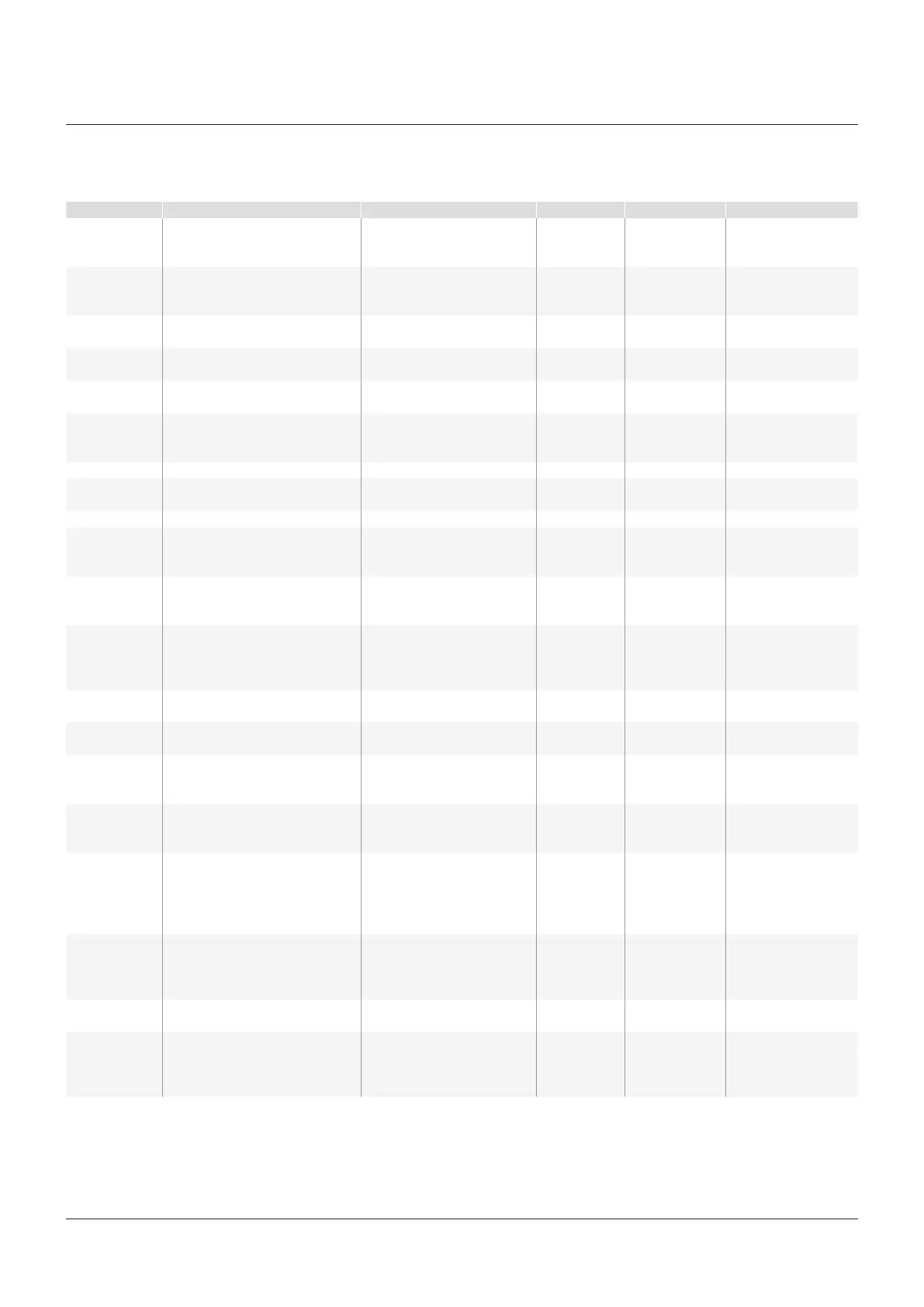

17.5.11 Alarm table

Available controls

Display message Condition for alarm Action Local Remote Alarm reset

High torque in

closing

Measured torque greater than the

relevant value configured in torque

set-up or stroke limits routine

Operate the actuator in opening

direction. Check the torque needed

to operate the valve

Only open Only open Open, control

High torque in

opening

Measured torque greater than the

relevant value configured in torque set-

up or stroke limits routine

Operate the actuator in closing

direction. Check the torque needed

to operate the valve

Only close Only close Close, control

Jammed valve in

closing

No position change after receiving a

close control

Check status of actuator and valve

mechanical parts

Only open Only open Open, control

Jammed valve in

opening

No position change after receiving an

open control

Check status of actuator and valve

mechanical parts

Only close Only close Close, control

Motor thermostat Motor thermostat open for high

temperature in the motor windings

Wait until the motor cools down Not available Not available When thermostat closes

Internal

temperature

Temperature inside the actuator

enclosure higher than 90°C or lower

than -40°C

Ambient temperature too high or

too low. Verify insulation among

actuator and heat source

Not available Not available Control temperature

<90°C or >-40°C

Position sensor Value of the actuator position

not valid Replace position sensor or recalibrate

both stroke limits

Not available Not available Position signal

correct

Speed sensor Measure of motor speed not valid Replace speed sensor Not available Not available Speed signal correct

Mid travel alarm

in OP

The valve does not move in presence of

an open control

Check status of actuator and valve

mechanical parts. Recalibrate both

stroke limits

Only close Only close Close, control

Mid travel alarm

in CL

The valve does not move in presence of

a close control

Check status of actuator and valve

mechanical parts. Recalibrate both

stroke limits.

Only open Only open Open, control

Main voltage Main voltage lower than -20% or higher

than +20% of the value stated in the

nameplate menu

Check main voltage supply and

frequency on terminals L1, L2 and

L3. Check that wires section is

correct

Not available Not available Main voltage correct

K1 contactor The test routine reports a failure of K1

(coil or auxiliary contact)

Check the contactor Opposite

direction

Opposite direction Control in opposite

direction

K2 contactor The test routine reports a failure of K2

(coil or auxiliary contact)

Check the contactor Opposite

direction

Opposite direction Control in opposite

direction

Configuration

object nr.

The check sum of the EEPROM memory

that contains the configuration data is

wrong

Re-configure all parameters

(see next page)

Not available Not available Memory okay

Hardware nr. The diagnostic program detects

some malfunction in the electronics

controlling the actuator

Some circuit is damaged and does

not work (see details next page)

Not available Not available Hardware okay

Low lithium

battery

The voltage of the lithium battery is

too low (only detected if the battery is

present and the relevant parameter

of the miscellaneous routine is set to

‘present’)

Change lithium battery Available with

main voltage

Available with main

voltage

Lithium battery okay

Lost phase The alarm appears only with 3–phase

main supply. The alarm is generated in

case of fault of one of the phases that

supply the actuator transformer

Check main power supply on

terminals L1, L2 and L3

Not available Not available Phase okay

Request signal The analog 4-20 mA signal is not correct Check the external 4-20 mA

generator and wiring

Available Positioner function

not available

4-20 mA input okay

EFS mid travel The position is >4% in ESD action and

often 3*reset time

Check reset time. Check electrical

stroke limits. Check mechanical

stops

Not available Not available Electrical actuator

command after the clutch

has been re-energized or

by local operator interface

Loading...

Loading...