BA-EN-HydroStar V3.1 page 18

7.3 Motor connection

• Insert the motor cable into the M25 threaded cable connection so that the jacket is pushed

through by approximately 50 mm.

• Securely tighten the threaded cable connection.

• Connect the motor supply line to the terminal strip according to the colour coding.

7.4 Extending the motor supply line

NOTE: Observe the minimum cross-section of 16 mm²!

If it is necessary to lengthen the line, observe the motor's rotation direction.

If the turbine is running in the wrong direction, invert the two connection lines.

• Shorten the original motor supply (3 x 6mm²) line to ≤ 5 m (minimum 2 m)

• Extend up to a total length of 30 m with a cable cross-section of 16 mm²

fine wired!

• To extend the turbine cable, the original BINDER 3x16 mm² cable is recommended! (Art.

No.: 5300115)

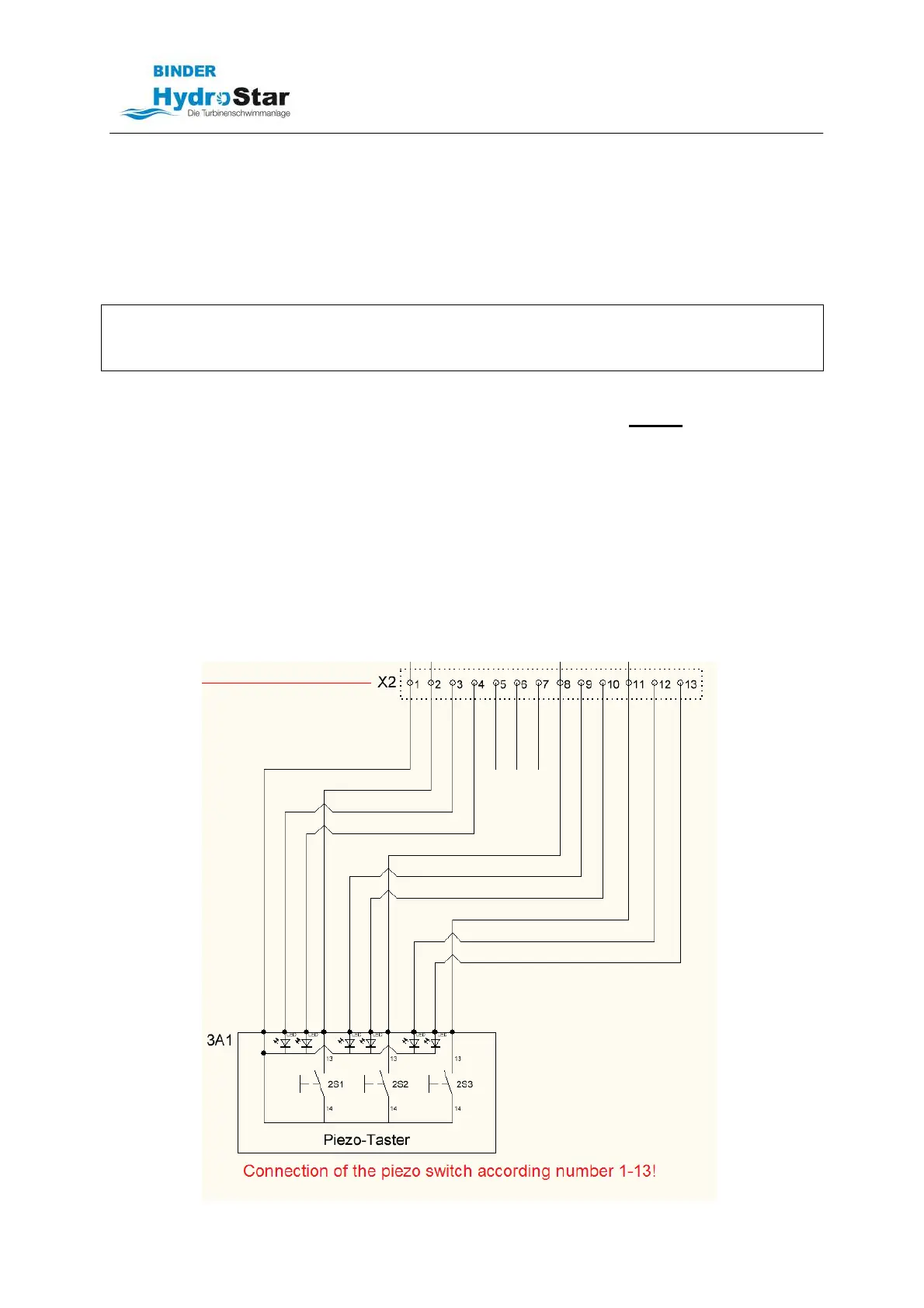

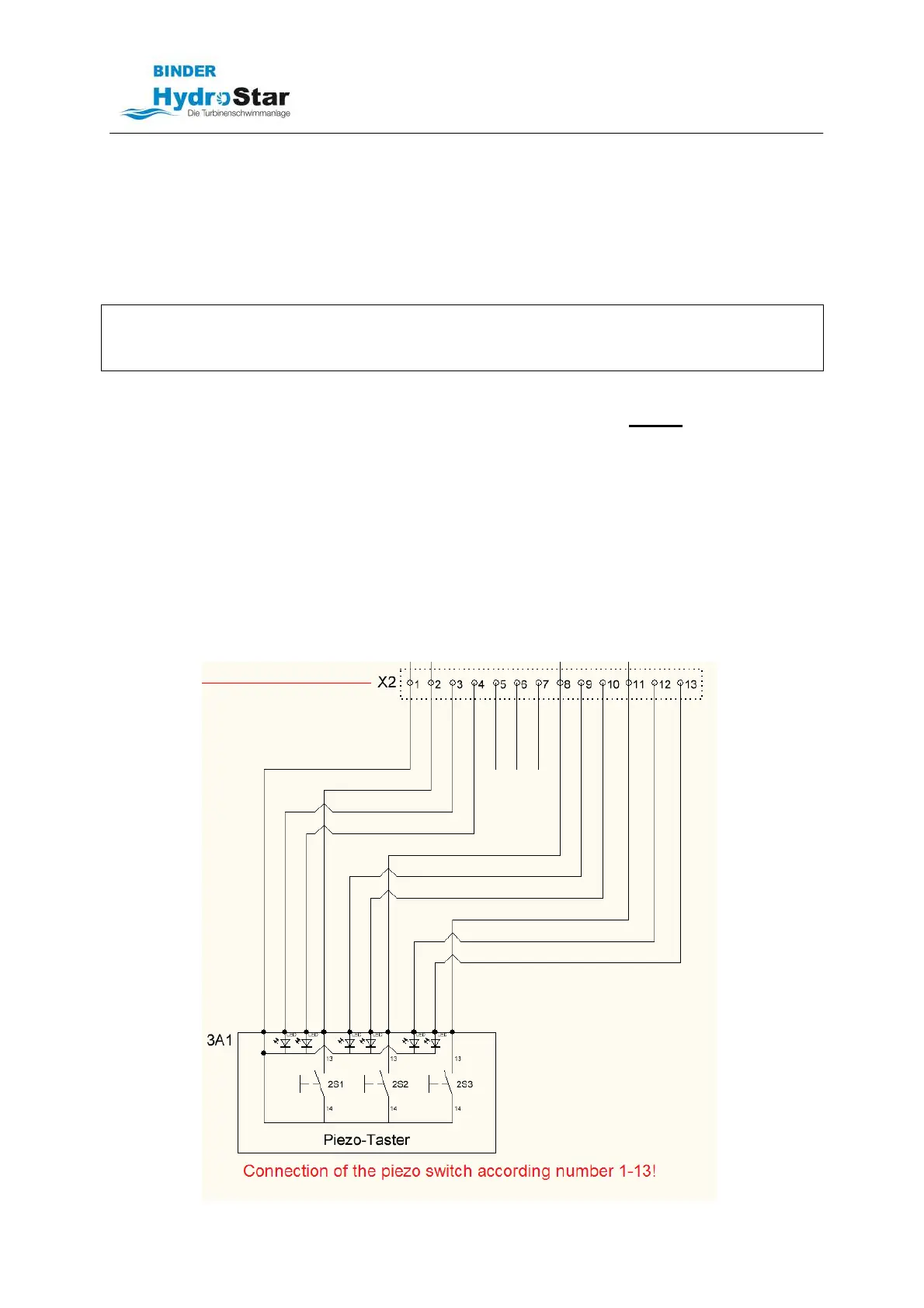

7.5 Connecting the HydroStar PIEZO Tri

• The connection cable is a 14-wire cable with cross-section of 0.5 mm

2

.

• The cable can be lengthened with an equivalent cable up to 30 m.

• It must be ensured that the wires are connected with the same numbering.

• An underground junction box for cable lengthening must have a watertight seal.

• Terminal strip X2 is used for connection.

• Connect the wire number according to terminal number.

• Please also observe the circuit diagrams included in delivery!

NOTE: Please also observe the circuit diagrams included in delivery!

Loading...

Loading...