68

english

4.5 Return valve

If a return valve has been installed, the pump has to be set up

(see point 7.2) so that the pump’s minimum delivery pressure

can exceed the valve’s closing pressure at any time.

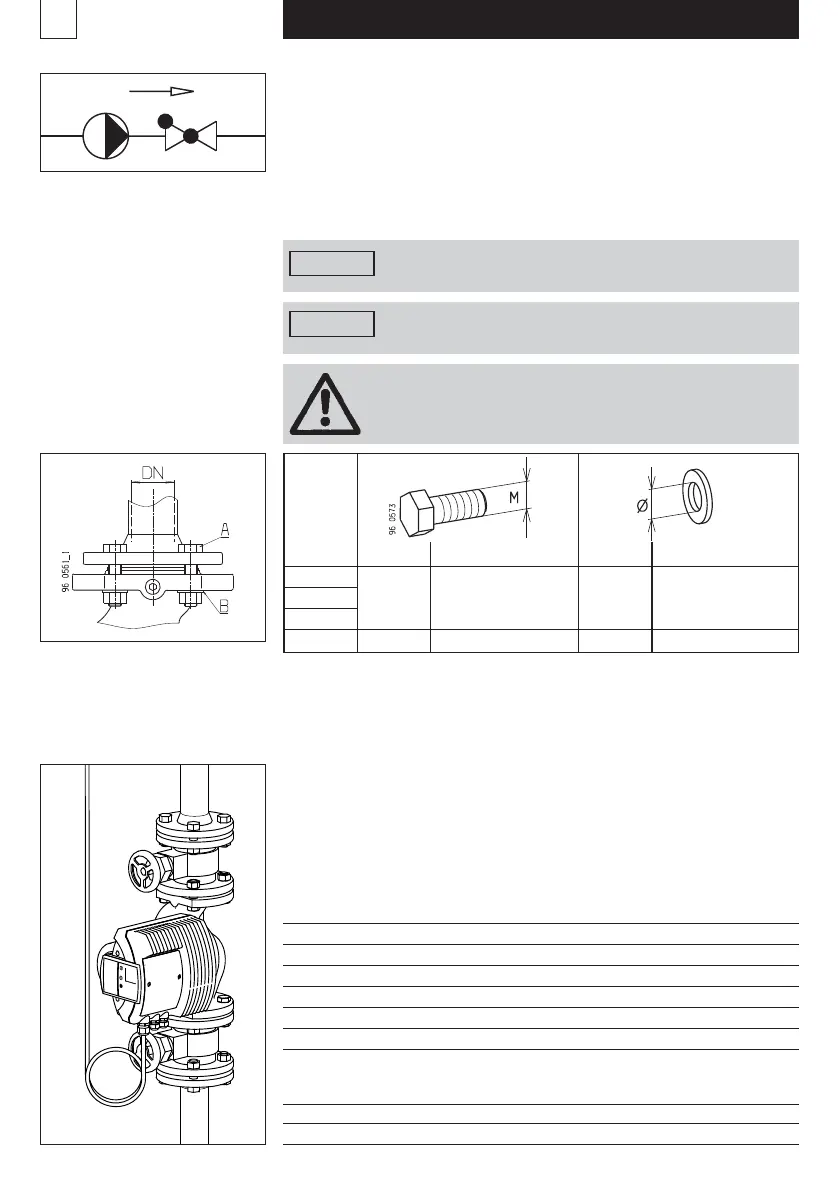

4.6 Flange connection

The pump flanges are bored with fixing holes PN6 / PN10 / PN16.

The plain washers «B» provided are to be installed

on the pump side to ensure that the flanges are securely fastened.

Admissible screw torque:

for M 12 <40 Nm

for M 16 <95 Nm

The installation of combination flange

with combination flange is not admissible.

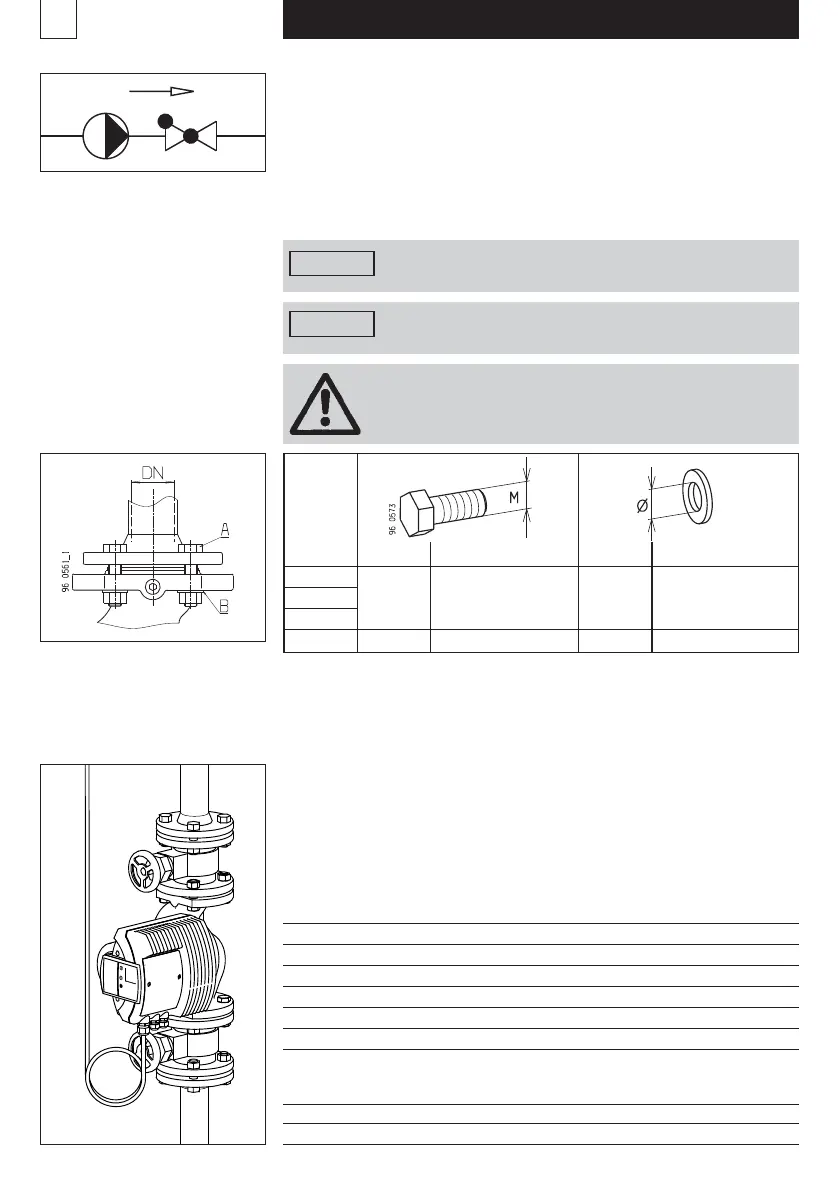

4.7 Minimum pressure

The minimum pressure in the pump connection at 75 °C

to ensure lubrication of the friction bearings:

Single pumps Twin pumps

A 402/402-1 V2, AW 402-1 V2 AD 402-1 V2 0,4 bar overpressure

A 501 V2 AD 501 V2 0,2 bar overpressure

A 502 V2 AD 502 V2 0,2 bar overpressure

A 651 V2, A 651-1 V2 AD 651 V2 0,35 bar overpressure

A 652 V2 AD 652 V2 0,35 bar overpressure

A 801 V2 0,35 bar overpressure

The values apply up to 500 m above sea level.

Additions for higher altitudes:

0.01 bar per 100 m of altitude

Addition for: 95 °C + 0,45 bar

Addition for: 110 °C + 1,10 bar

Install the sluice gate before and after the pump.

This prevents the fluid from being drained and refilled

when the pump is exchanged.

Use the appropriate screws

for the given nominal pressure PN.

Safety elements (such as spring lock washers)

are not admissible.

Warning

Special seals and screws must be used

for PN 10/16.

Warning

PN 6 PN 10 / PN 16 PN 6 PN 10 / PN 16

DN 40

DN 50 M 12 M 16 Ø 14 Ø 18

DN 65

DN 80 M 16 M 16 – –

A B

Loading...

Loading...