KW-231-112

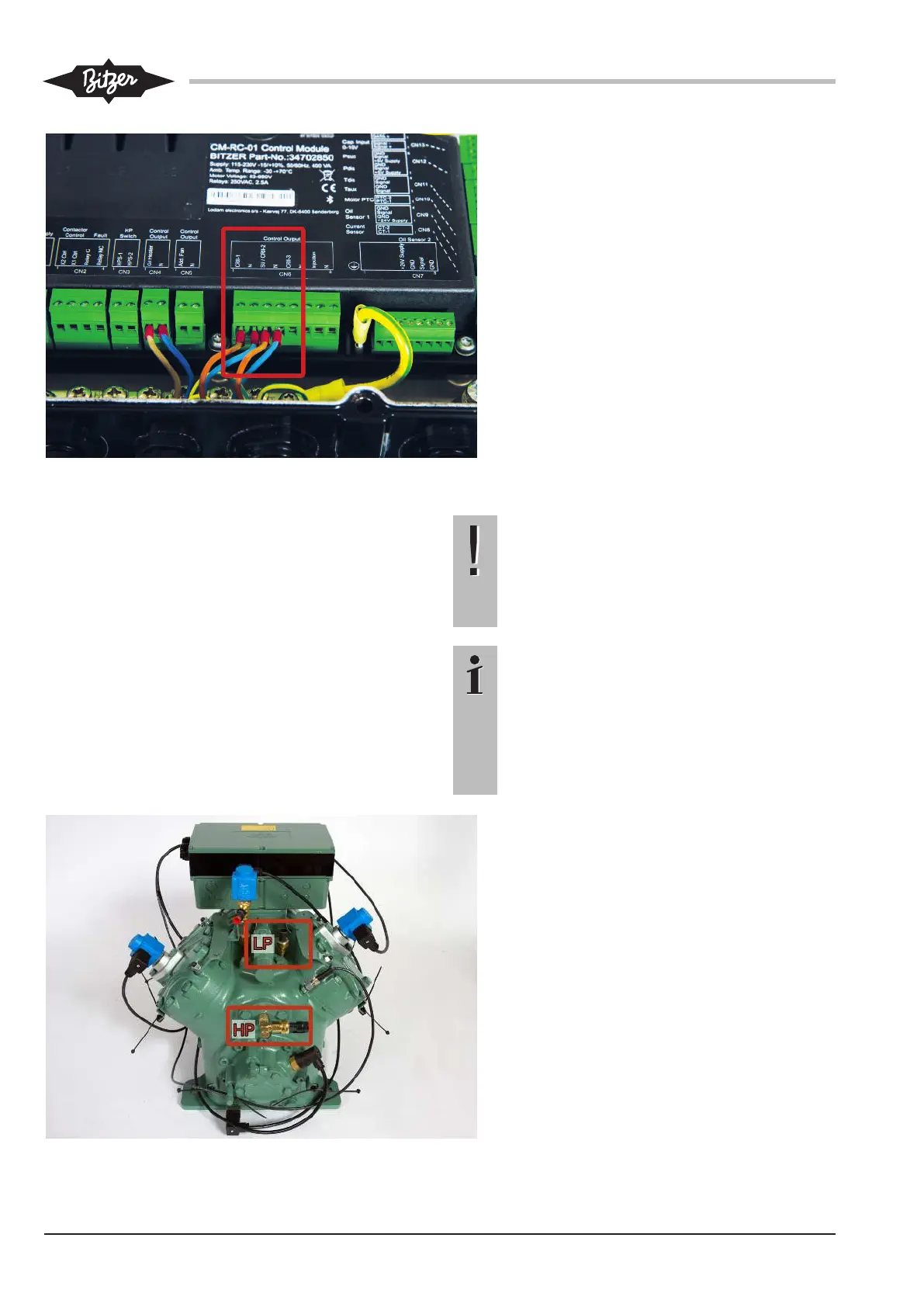

• Shorten the cables as needed, pass them

through the cable glands on the compressor

module into the module housing and connect

them to the CN6 terminal strip.

If no additional extension kits are mounted:

• Proceed with the other electrical connections on the

CM-RC-01 (see chapter Further electrical connec-

tions on the CM-RC-01, page 9).

• Lay the cables and close the cable ties (see chapter

Laying the cables, page 9).

• Screw the protective earth conductor onto the ter-

minal box cover and attach the cover to the module

housing (see chapter Screwing the cover onto the

module housing, page 10).

4.2 Mounting the "Pressure transmitter" extension kit

NOTICE

The two pressure transmitters must not be inter-

changed. They differ by the component number

engraved in the component:

High pressure transmitter: 2CP5-71-47.

Low pressure transmitter: 2CP5-71-49.

Information

Alternative mounting position for discharge gas

temperatures exceeding 135°C:

Connect the pressure transmitters to the dis-

charge gas line, as close as possible to the

valves using one refrigerant hose each. Length

of the refrigerant hose: at least 200 mm to avoid

overheating of the transmitter.

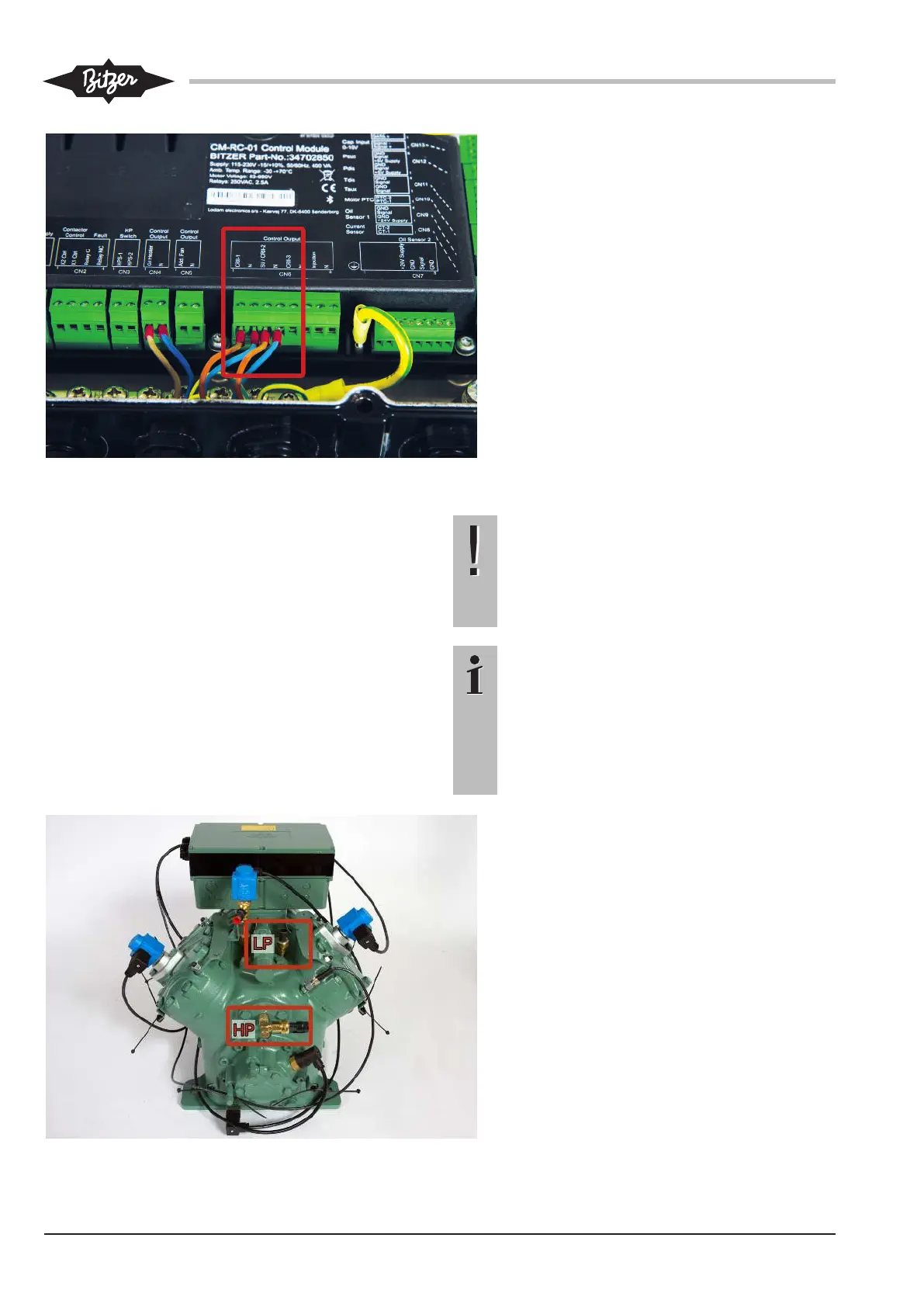

4-cylinder compressors 4JE-13Y .. 4FE-35(Y):

• Remove the sealing plugs from the connect-

ors marked by rectangles and clean the

threaded bores.

• Screw the enclosed screwed nipple (low pres-

sure transmitter) resp. T-piece (high pressure

transmitter) with Schrader valves into the

threaded bores.

• Then screw the high pressure transmitter

(2CP5-71-47) into place at the HP position

and the low pressure transmitter

(2CP5-71-49) at the LP position (tightening

torque 35-40 Nm). Do not insert a blanking

plate between screwed nipple and pressure

transmitter, since this will prevent the

Schrader valve from opening!

Loading...

Loading...