KW-231-114

NOTICE

Serious injuries are possible. New component

may suddenly become detached.

Check the thread.

Carefully screw in the new component. Observe

the tightening torques!

Perform a tightness test before commissioning!

After mounting all components of the liquid injection

system:

NOTICE

After assembly work on the compressor, there is

a risk of oil or refrigerant leakage

Perform a tightness test before commissioning!

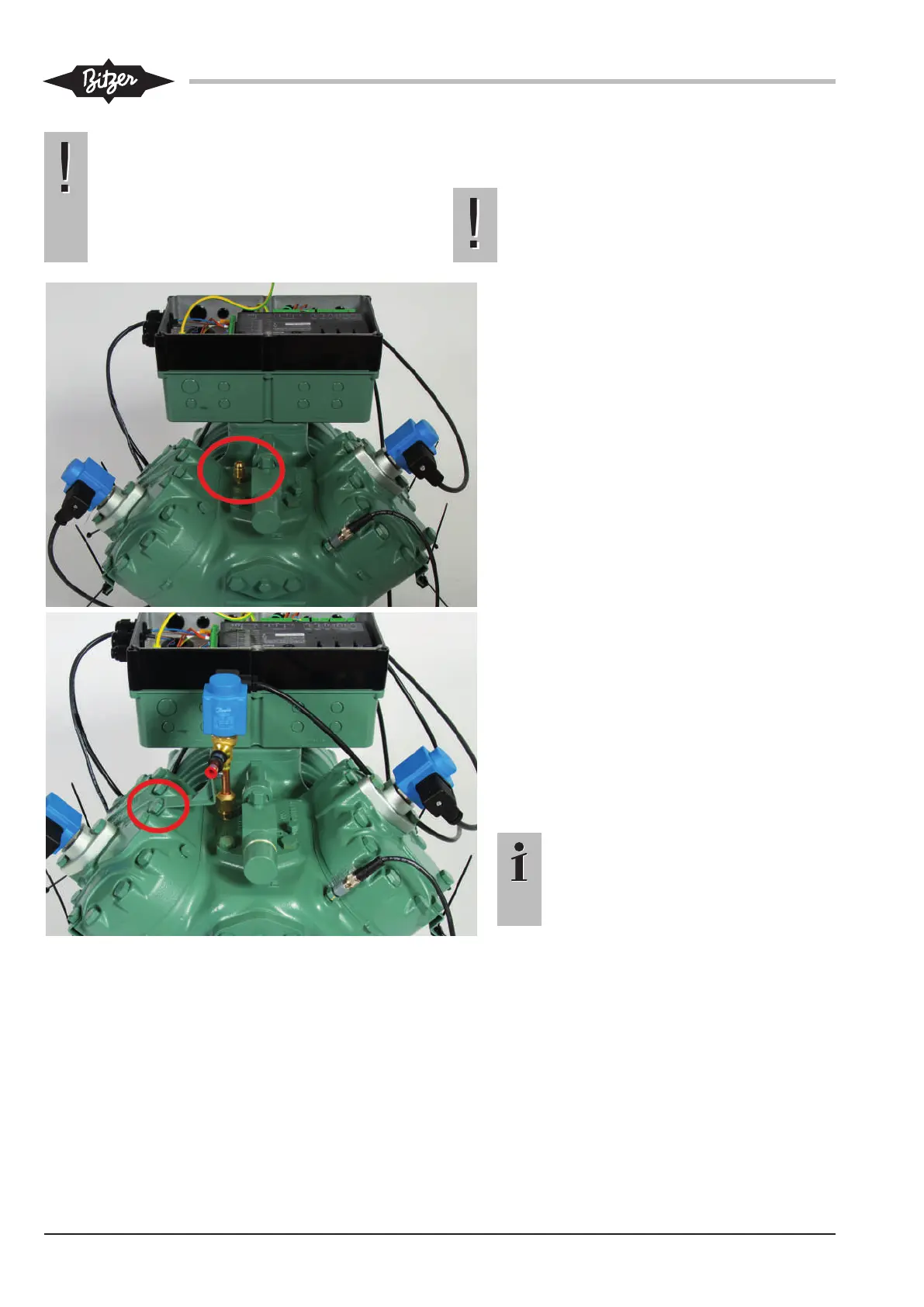

4-cylinder compressors 4JE-13Y .. 4FE-35(Y):

The 4-cylinder compressors are equipped with

an injection nozzle:

• Before installation, make sure that the injec-

tion nozzle is clean.

• Then remove the sealing plug (1/8 NPTF) and

screw the injection nozzle into place (tighten-

ing torque: 10-13 Nm).

• Wrap Teflon tape around the conical thread

(1/8 NPTF) to seal it.

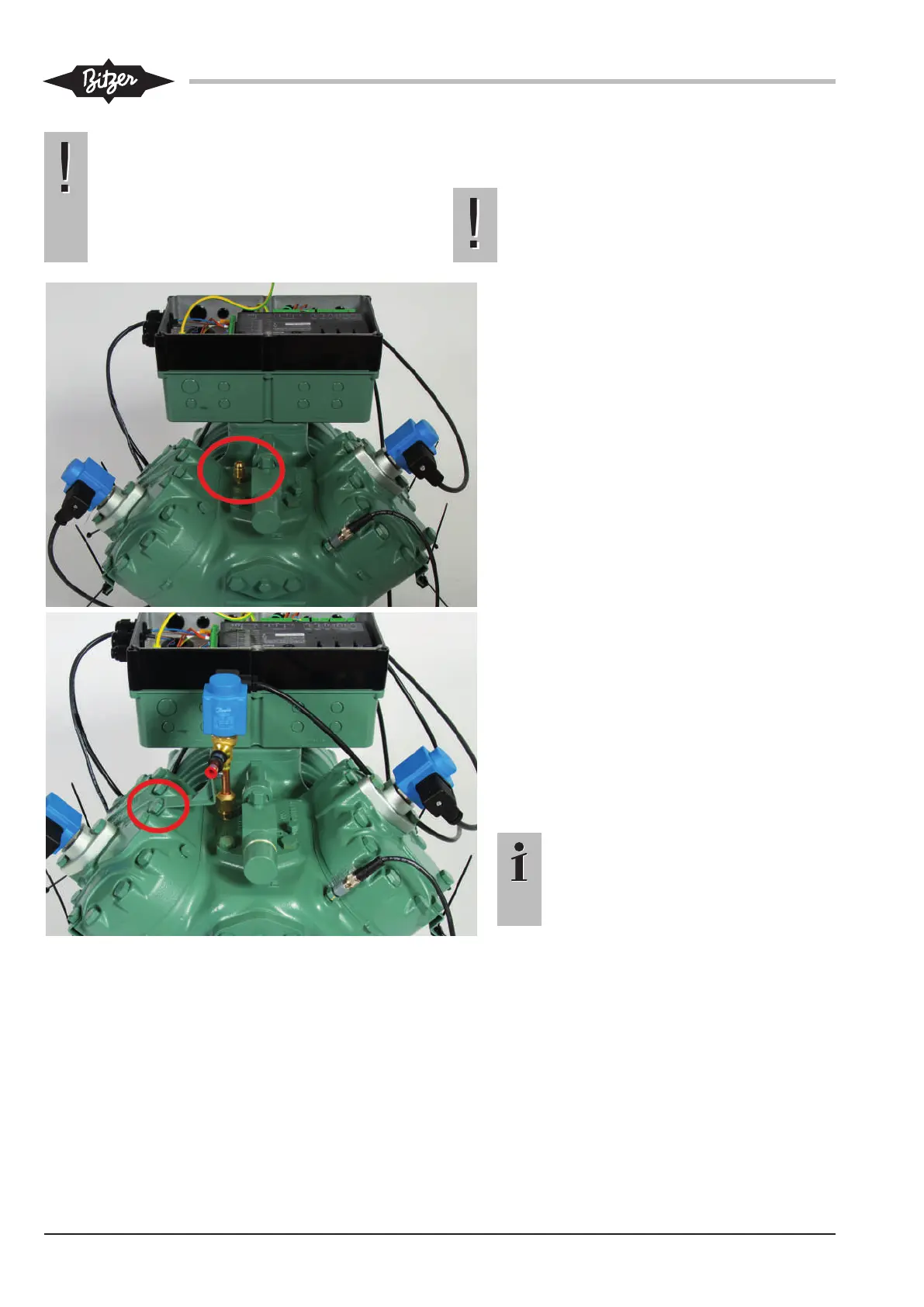

• Screw the injection valve into place. It comes

premounted to the connecting line (including

screwed joints) leading to the injection nozzle.

• To avoid undefined vibrations and tensions in

the connecting line, secure the injection valve

through the fixing plate on the cylinder head.

• To this end, loosen the corresponding screw

on the cylinder head and tighten it again with

the fixing plate inserted (tightening torque: 80

Nm).

• Press the solenoid coil onto the armature until

it engages.

• Insert the electric connector of the device and

screw it down (tightening torque 5 Nm).

Information

Due to the position of fixing plate and

pipe clip on the cylinder head, the direc-

tion of pipe entry into the valve needs to

be considered for installation.

Loading...

Loading...