PAGE 17

OM-8003 & 8004

Date Printed: Tuesday, February 08, 2005

Revision Date: 06-12-03

Note manifold pressures listed above. Read lighting instructions. Cycle unit on, back out brass screw a FEW

turns in the appropriate pressure test nipple as indicated below. Test for appropriate range, if regulator is not

properly set, replace. Stick conversion marking on the panel inside the right door, just above the valve. Fill out

conversion information on label inside of the left door on unit.

ADJUST PILOT AS NECESSARY, SEE ILLUSTRATION ABOVE FOR PROPER SIZE AND LOOK OF PILOT LIGHT.

PILOT CONVERSION LP OR NATURAL GAS

CONVERSION KIT SHOULD INCLUDE REGULATOR, MAIN BURNER ORIFICE, AND PILOT ORIFICE.

CAUTION: Before proceeding with the conversion the gas supply must be shut off prior to disconnecting

the electrical power.

1. ................Remove the 2 screws holding the regulator plate. Remove regulator and gasket.

Position new gasket over pins and install new regulator with notched corner up.

2 .................Open the front access door.

3. ................Remove embers and logs.

4. ................Lift front of burn tray and remove through door.

5. ................Using a 1/2” wrench, break the compression fitting loose on the pilot line.

6................. Locate the 2 screws securing the pilot assy to the bottom of the fire box. Remove screws.

7. Change the main burner orifice by unthreading existing orifice from fitting with 1/2 inch wrench.

Replace with an appropriate orifice. Remove pilot line by unscrewing 1/2 inch brass fitting. Remove the

pilot orifice. Replace with an appropriate pilot orifice.

8. ................Reverse steps 1 to 6 to complete conversion.

9 .................Fill in the conversion label on the label plate with the conversion information and fill out the label

#0630 that came with the conversion kit and place it on the inside of the side door near the valve.

WARNING: EACH CONNECTION MUST BE INSTRUMENT CHECKED OR SOAP CHECKED FOR LEAKS

WITH GAS PRESSURE ON.

BURNER CONVERSION ROBERSHAW VALVE

LP OR NATURAL GAS

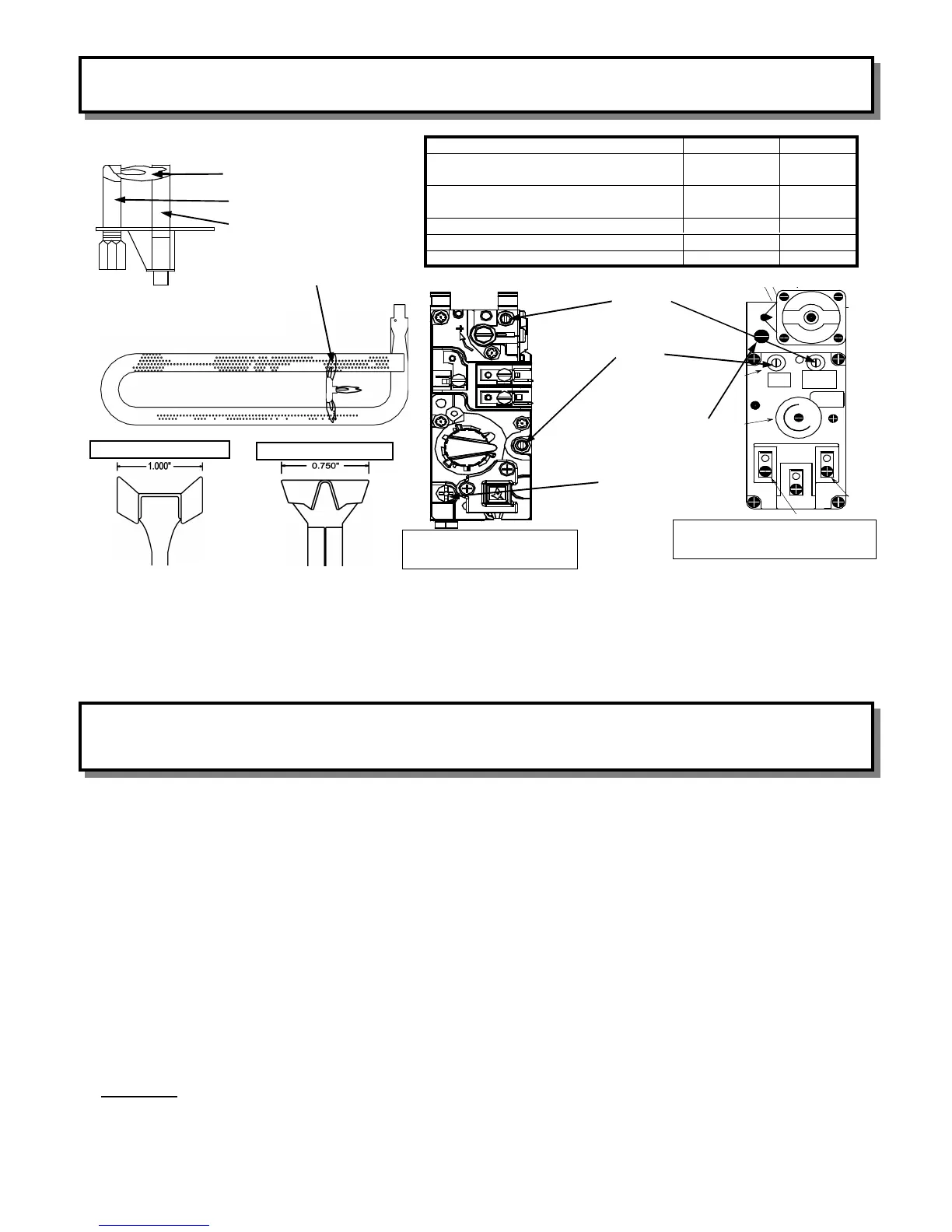

NATURAL GAS LP GAS

Manifold Pressure (In w.c. / kPa) 3.5 / 0.87 11.0 / 2.74

Collecteur de pression (In w.c. / kPa)

Manifold Pressure Lo setting (In w.c. / kPa) 1.3 / 0.32 2.7 / 0.67

Collecteur de pression à bas rendement (In w.c. / kPa)

Minimum Inlet Pressure (In w.c. / kPa)` 4.5 / 1.12 12.2 / 3.04

Max Inlet Pressure (In w.c. / kPa) 10.5 / 2.61 13.0 / 3.27

Input (but/hr) 35,100 35,800

Robertshaw Pilot

Pilot Flame Should

Look Like This

Thermopile

OUTLET

PRESSURE

TAP

INLET

PRESSURE

TAP

ROBERTSHAW

PILOT ADJUSTMENT

SCREW

(REMOVE CAP TO ACCESS

ACTUAL ADJUSTMENT

SCREW)

PILO

IN

ON

TH

TP

TP

TH

OU

P

I

L

O

OF

TH

TP

TH

TP

L

O

H

I

VENT

OUT

IN

ON

OFF

P

I

T

O

L

PILOT ADJ.

OUT

IN

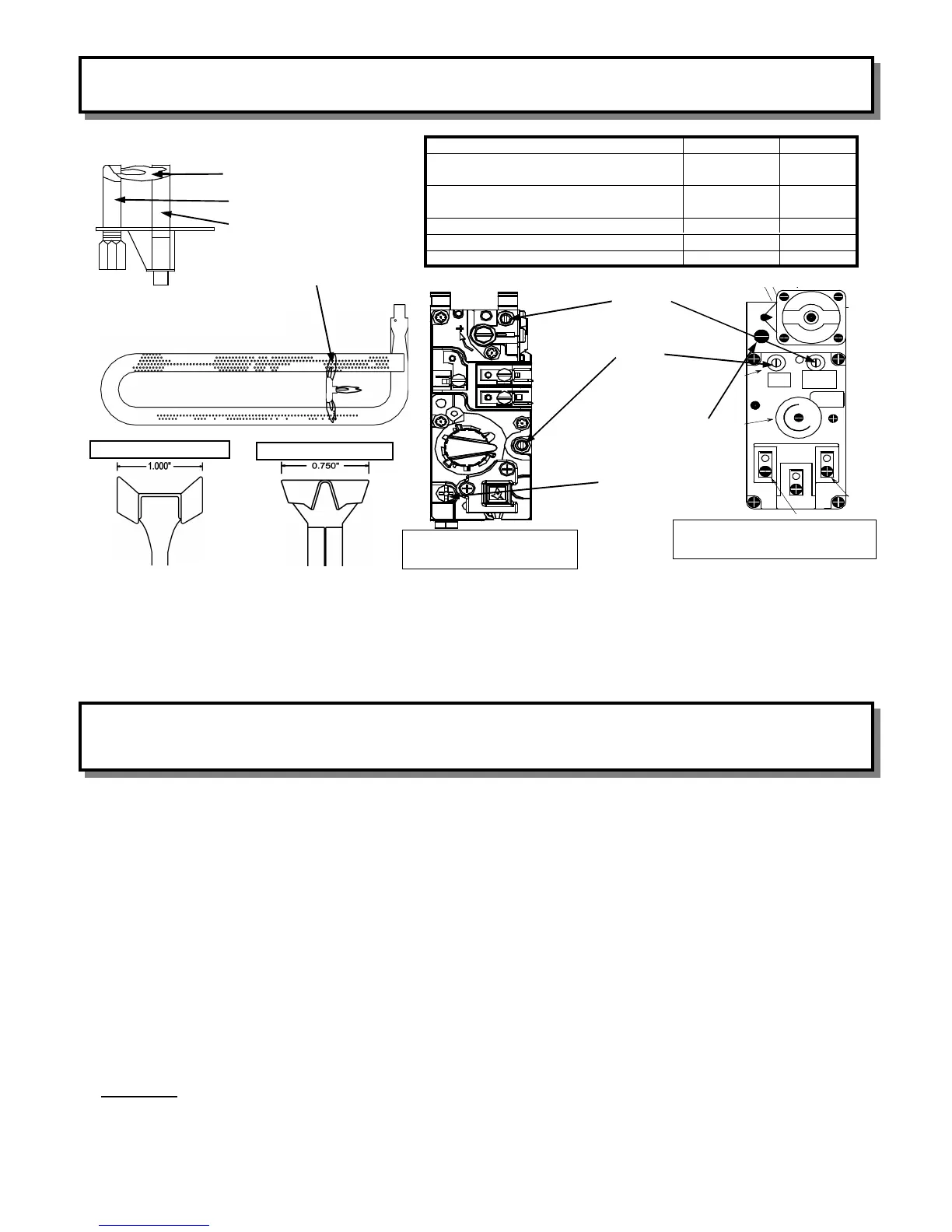

HONEYWELL

HONEYWELL PILOT HOOD

ROBERTSHAW PILOT

Top View Of Burner

Pilot Flame Should

Look Like This

Loading...

Loading...