7 - Troubleshooting

Error Cause Solution Comment

Assembly machine is driving against an

object (e.g. swivel stop)

Remove object none

Feed switch was released before the

drilling depth was reached

Work top height (thickness)

Cam brake set too high

The swivel stops were not set properly

on the ruler.

Keep feed switch engaged until the drilling

depth has been reached

Put work top underneath until a height of 24

mm has been reached

Open restrictor valve slightly

Check positions and stops and correct if

necessary

none

See chapter 8 - Ap-

pendix

See point 3.1.9

none

Ruler not set properly Set ruler to the 0 point See point 1.1.3

Chips between the ruler and the work

piece

Remove dirt and chips none

Extension ruler is not attached properly Check ruler attachments and extension -

check spacing of both rulers

none

Swivel gear not engaged Allow index bolts to engage See point 3.1.3

Drillings are off centre

or in the wrong posi-

tion

Work piece is not positioned on laser

marking line

Position work piece correctly none

Work piece cannot be positioned

on the laser marking line

See following work steps none

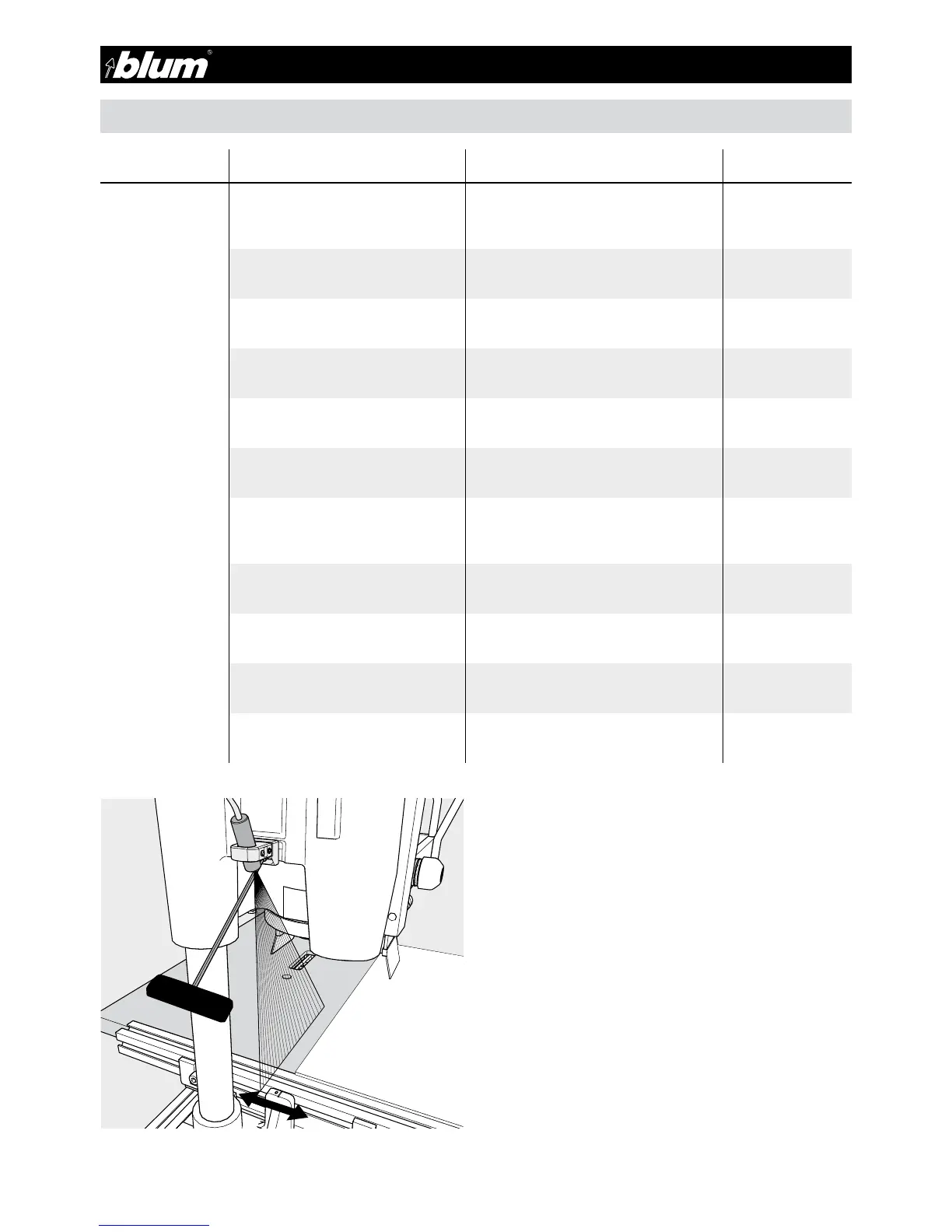

• Slightly loosen sub-assembly screw using a wrench (counter-

clockwise)

• Set laser line to the zero position

• Tighten screws using wrench (clockwise)

Adjusting laser to zero marking line:

7.1 - Error during drilling

Loading...

Loading...