English–101 609 929 J73 • (06.03) PS

5 OPERATING INSTRUCTIONS

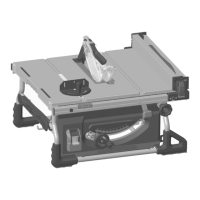

Transport and Working Positions

Before all work on the machine, pull the mains

plug.

Transport Position

Turn the hand wheel 12 in the clockwise direction until

the teeth of the saw blade 35 are below the saw table

11.

Working Position

Turn the hand wheel 12 in the counter clockwise direc$

tion until the teeth of the saw blade 35 protrude ap$

prox. 5 mm above the work piece.

Ensure that the protective hood is properly posi>

tioned. When sawing, it must always rest on the work

piece.

Changing the Tool

Before all work on the machine, pull the mains

plug.

Wear gloves when mounting the saw blade. Danger of

injury exists for contact with the saw blade.

Select a saw blade suitable for the material to be

worked.

Use only saw blades whose allowable rotational speed

is as least as high as the no$load speed of the power

tool.

Use only saw blades that comply with the characteris$

tic data given in these operating instructions and have

been tested according to EN 847$1 and appropriately

marked.

Pay attention when changing the saw blade that the

cut width is not smaller than 2.6 mm and the basic

blade thickness is not larger than 1.8 mm. Otherwise,

the danger exists that the riving knife (2.5 mm) will jam

in the work piece.

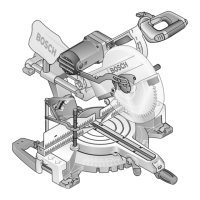

Removing the Saw Blade

Turn the hand wheel 12 counter clockwise to the stop

so that the saw blade 35 is in the highest possible po$

sition above the saw table.

With the enclosed ring spanner 17, lift the insert plate

3 at the front (see Figure ) and remove it from the

cut$out 42.

Turn the hex$nut 56 with the ring spanner 17 (23 mm)

provided and pull the spindle lock 54 at the same time

until it engages. (see Figure )

Hold the spindle lock pulled and unscrew the hex$nut

56 in the counter clockwise direction.

Take off the clamping flange 55. Remove the saw

blade 35. (see Figure )

Mounting the Saw Blade

If necessary, clean all parts to be mounted.

Place the new saw blade on the tool spindle 57.

(see Figure )

Do not use a saw blade that is too small. The gap

between the saw blade and the riving knife can be a

maximum of 5 mm.

When mounting, observe that the cutting

direction of the saw teeth (arrow on the

saw blade) agrees with the direction of the

arrow on the protective hood!

Place on the clamping flange 55 and the nut 56. Pull

the spindle lock 54 until it engages and tighten the nut

56 in the clockwise direction.

Reinsert the table insert plate 3.

Dust/Chip Extraction

(see Figure )

Take protective measures when dust is pro>

duced while working that can be detrimental to

health, combustible or explosive. For example,

some dusts are considered carcinogenic. Wear a dust

protection mask and use dust/chip extraction, if it can

be connected.

External Dust Extraction

For extraction, a vacuum cleaner hose (35 mm dia.)

can be connected to the sawdust ejector 30.

To increase the vacuuming performance, an additional

dust extractor can be connected to the vacuuming

connection piece 5.

The vacuum cleaner must be suitable for the material

to be worked.

When vacuuming dry dust that is especially detrimen$

tal to health or carcinogenic, use a special vacuum

cleaner.

A1

A2

A3

A3

B

PTS10_WEU.book Seite 10 Donnerstag, 23. März 2006 11:47 11

Loading...

Loading...