29

6 Operation 6

6.1.11 Opening the Loading Door

Never leave the loading door standing open!

Before each start, make sure that the loading door is closed.

During longer standstills, concentrations of the solvent gas can form.

For this reason, the machine control system has been designed to lock the loading door after a standstill

of 1 minute.

You can unlock the door with the " ⇑ " button for up to 9 minutes.

After 10 minutes, you cannot open the loading door until after you have started the "DEODORIZING"

program (P34) and the horn has stopped sounding.

Caution

Attention:

When neither current nor compressed air is present or

when the program has been interrupted, a mechanical

EMERGENCY opening is possible.

The trained user is permitted to carry out an EMERGENCY opening only when the program has stopped

and the cage is not turning. Open the button trap cover before the emergency opening.

After removing garments that have not finished drying, place them in a solvent-tight and solvent-resistant

transport container.

Follow safety regulations (wear protective gloves, room ventilation, etc.).

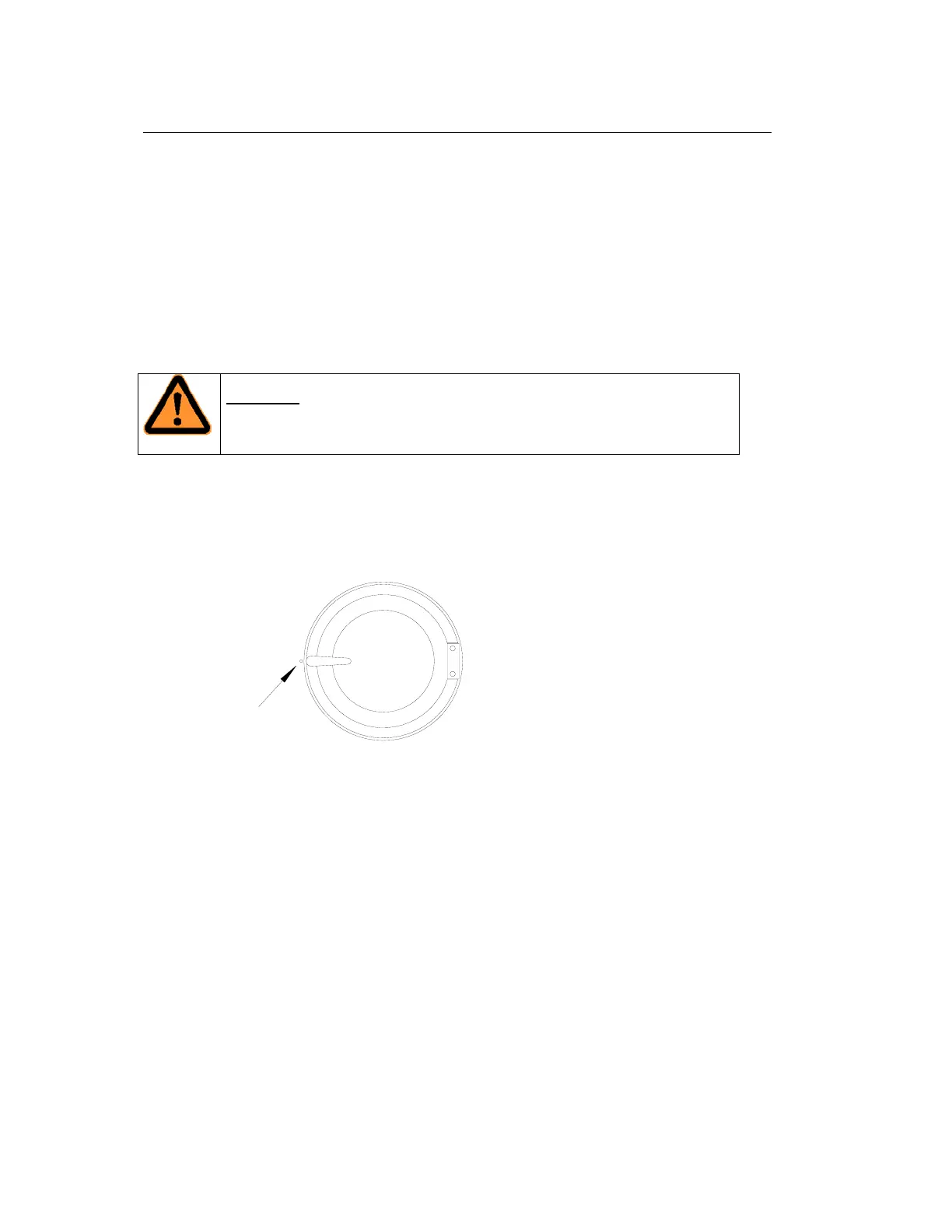

Emergency release

703887-03-B-01

There is an 8-mm (.3 in) ∅ bore hole in the paneling, to the left of the loading door, that you can use to

release the lock.

Use a screwdriver to press the bolt to the left and open the loading door.

After correcting the error, close the loading door and cover and continue the program by pressing the

"Start" button.

6.1.12 Performing a Test Run

Load the machine with test garments (note the filling capacity!)

Start program P2 (see 6.2 Automatic Operation - Brief Instructions) and check the settings and operating

values listed under Point 5 during the cycle and correct if necessary.

To ensure proper drying, do not load the machine with more than the maximum filling capacity.

Never take out garments that have not dried completely.

P12

Loading...

Loading...