32

7 Functional Units 7

7.1 Tanks

7.1

The work tank contains solvent, which is used over and over. The solvent is pumped from the work tank

to the cage. If there is not enough solvent in the work tank, fresh solvent is taken from the clean tank.

After the garments have been cleaned, the solvent is pumped back to the work tank or to the distillation

system. Machines without a detergent solution cooler have a water-cooled tank cooler built into the work

tank.

The clean tank holds clean solvent that has been recovered from the distillation and drying processes.

When the clean tank overflows, it fills up the work tank again.

A sacrificial anode in the clean tank protects against corrosion.

Tank 3 (optional equipment) is an extra tank for special applications.

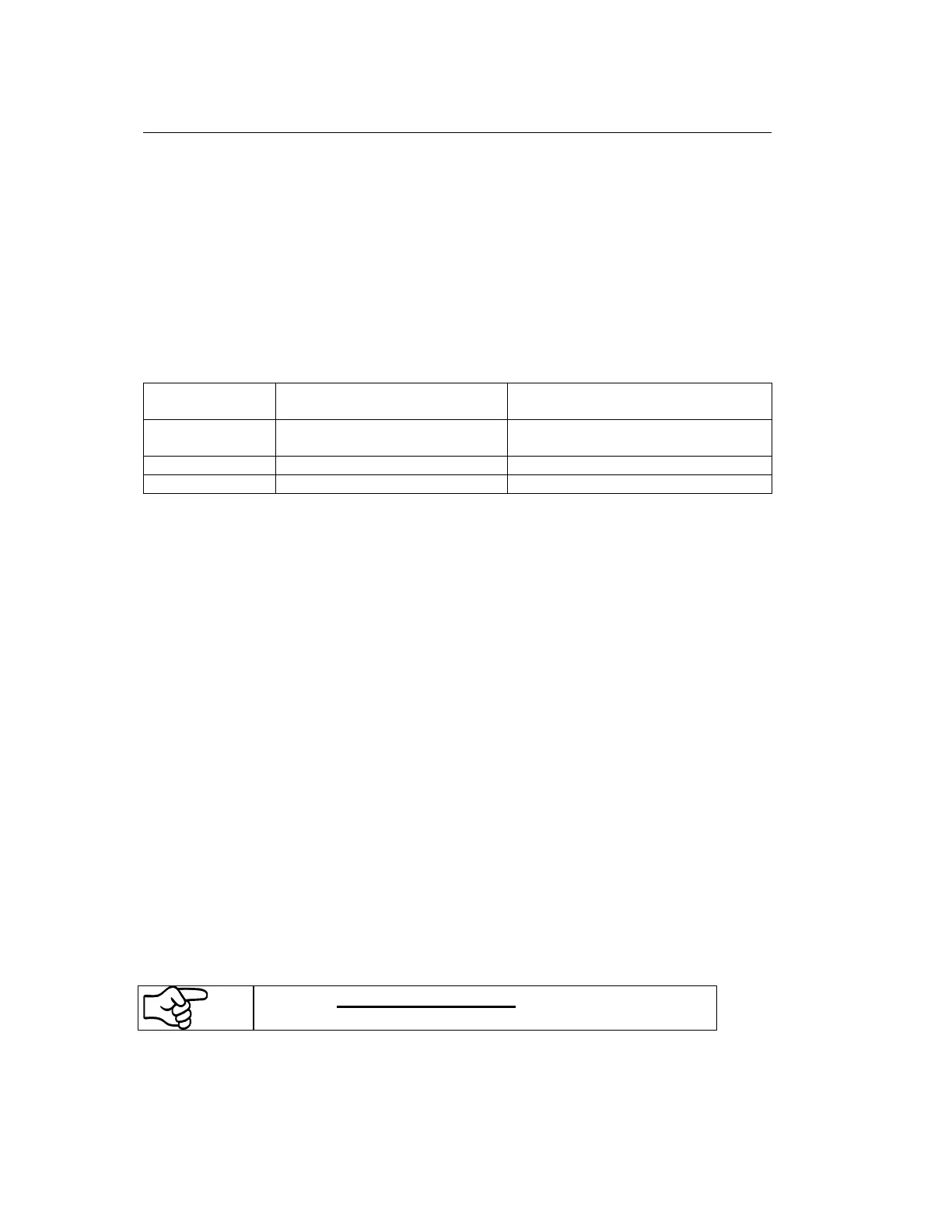

Filling volume P12/P15 Recommended filling amount

P12/P15

Work tank 120 l /145 l (31.7/38.3 US gal) 60 l/70 l (15.8/18.5 US gal)

(high level)

Clean tank 80 l/95 l (21.2/25.1 US gal) 80 l/95 l (21.1/25.1 US gal)

Tank 3 100 l (26.4 US gal) -

7.2 Solvent Pump

7.2

The solvent pump is a self-priming vertical pump.

Delivery rate up to 125 l/min (33 US gal/min)

7.3 Solvent Cooling System (Optional Equipment)

7.3

The detergent solution cooler works over a heat exchanger that is cooled with a cooling agent.

The cooling of the solvent is set to 15 °C (50 °F) in gentle programs.

The cooling is controlled over a thermal sensor at the heat exchanger inlet.

During each bath with detergent solution cooling, the program remains stopped (the cage does not

move) before pumping up until the selected detergent solution temperature has been reached.

Then the detergent solution temperature is monitored while the program runs.

Press function key "F4" to display the detergent solution temperature.

7.4 Work Tank Cooling System

7.4

Machines without detergent solution cooling always have a water-cooled cooling coil built into the work

tank.

7.5 Economy Filter for Solvent

7.5

Economy filter 1 (economy filter 2 is optional equipment)

The economy filter is a filter without a precoating (without filter powder).

Perform filter maintenance when the filter pressure is 1.5 bar or after a maximum of 50 cycles.

You can also use the economy filter with filter powder.

Before starting the filter maintenance program P10 (or P35 for filter 2), place the required amount of

filter powder (1.2 kg/2.6 lb) into a bag in the cage.

Attention! Do not use filter powder

on machines with an

emission-free still rakeout system.

After you start the filter maintenance program, all necessary processes will be carried out completely

automatically (draining, spinning, rinsing, precoating, cage drying with reduction).

A signal sounds after the reduction.

After you have removed the empty bag from the machine, the machine is ready for use again.

P12

Loading...

Loading...