56

11. Maintenance 11.

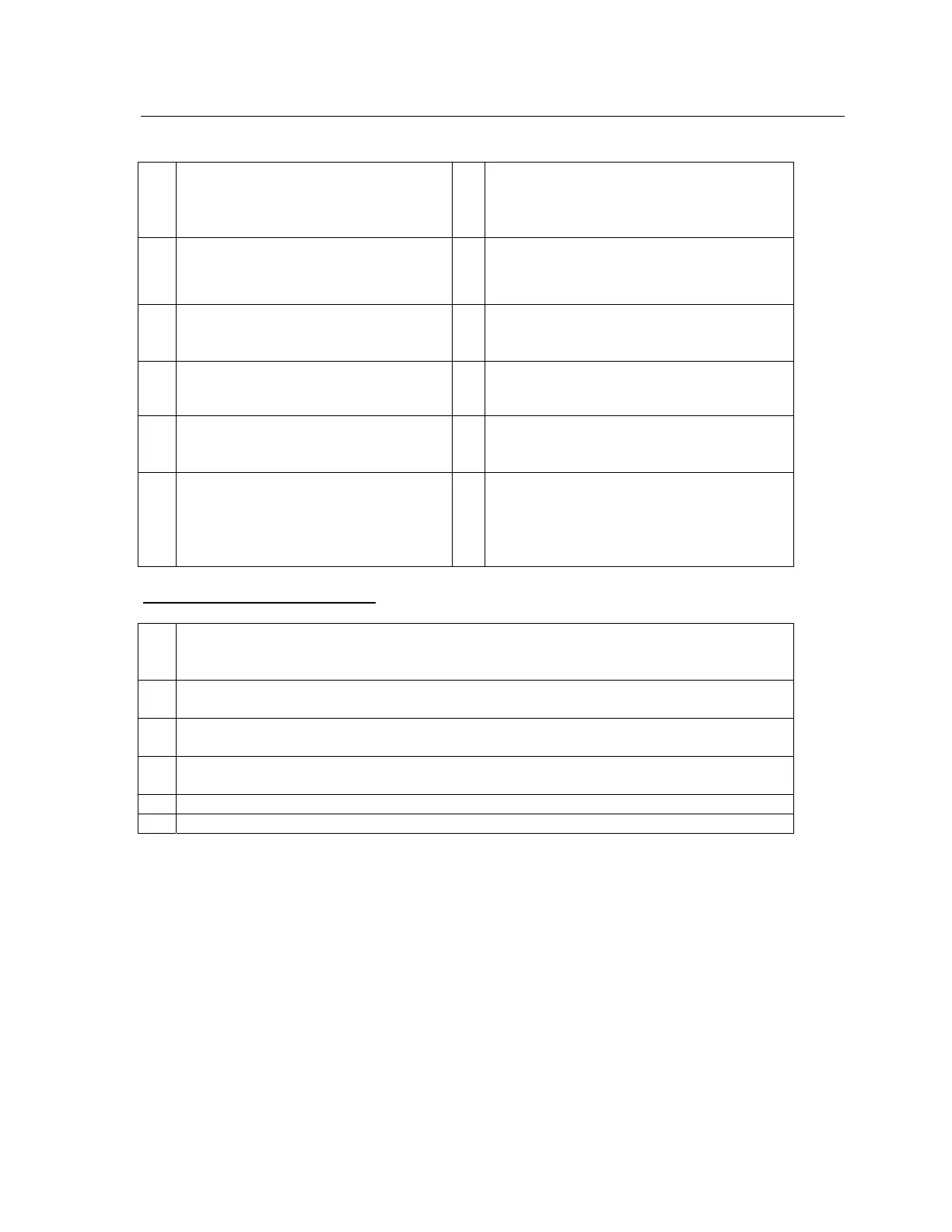

17 Process water collecting tank:

Dispose of process water in

accordance with regulations. Do not

allow to overflow!

23 Safety separator drain *:

You can completely drain the safety

separator when needed.

18 V belt:

Check semi-annually and retension if

necessary.

24

Sight-glass, safety separator *:

Remove and clean sight-glass when it is

dirty.

Sight-glass, tank 3:

Semi-annual tank cleaning through

the sight-glass opening.

25 Inspection cover, cage flange:

Open when needed, remove lint on the

back wall of the cage.

20 Drying controller DRYSTAT:

Check for dirt.

26

Detergent solution cooler drain:

Drain when needed, open tank and clean

inside.

21 Grease nipple, cage:

For monthly lubrication of the cage

bearing.

27

See point 1.

22 Process water drain valve *:

Drain for process water purification or

disposal when the liquid level is at the

mark in the upper third of the sight-

glass.

28

Venting and aeration filter:

Replace as needed, or clean or replace

the mat as needed.

19

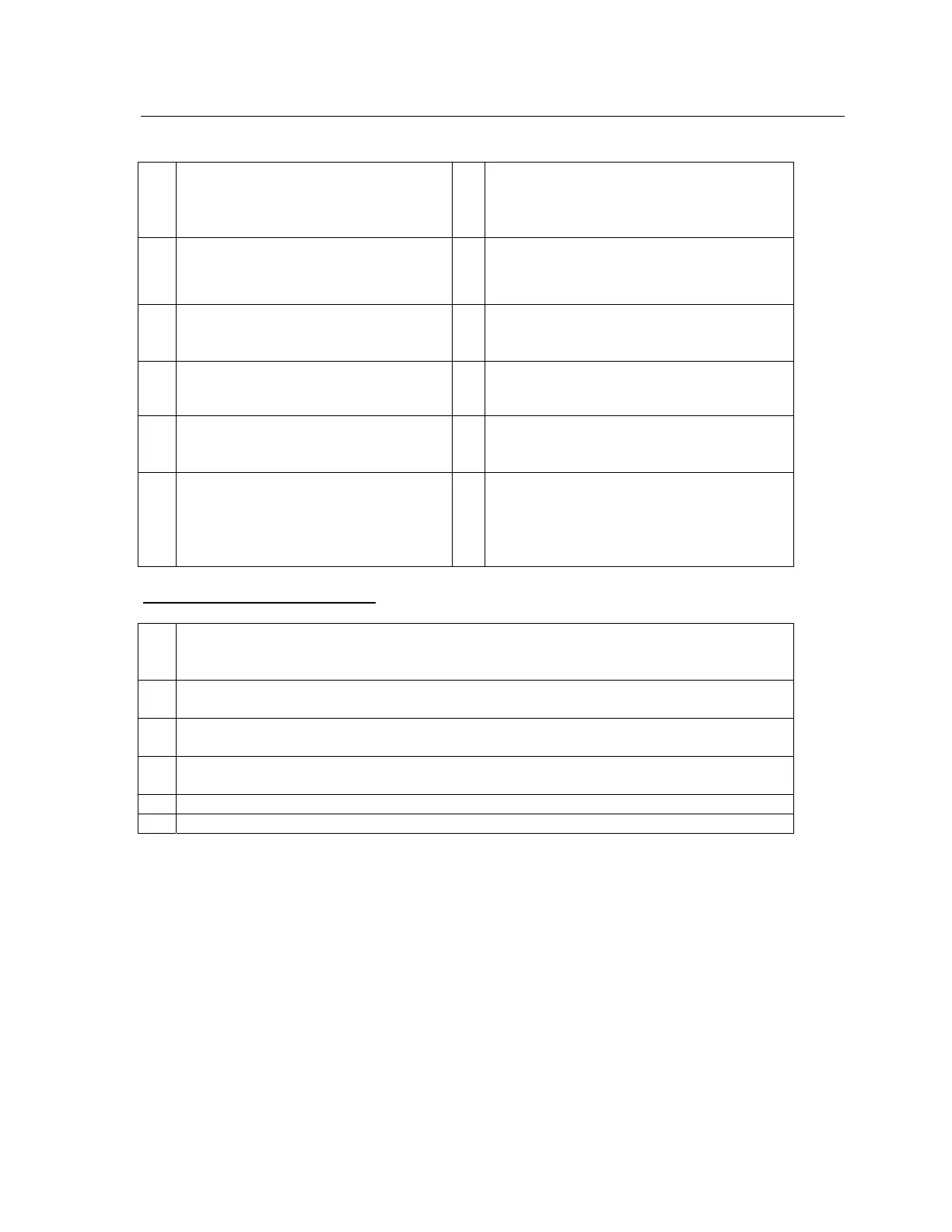

Additional maintenance points:

- Sight-glasses tanks I and II (front side):

Semi-annual tank cleaning through the sight-glass opening (after screwing off the front

paneling).

- Overfill sensor, disposal vessel:

Check function.

- Filter pressure gauge (front side):

Perform filter maintenance at 1.5 bar pressure (program P10)

- Sight-glass, filter circuit (front side):

If there is insufficient clearing of the solvent, check the filter disc for damage.

* only on machines that conform to the EN ISO 8230 standard

P12

Loading...

Loading...