Pre Start Inspection and Operation

3.6

10. Check for loose or missing fasteners.

• Inspect for any loose or missing bolts.

• Tighten or replace any missing bolts immediately.

11. While you are performing the daily maintenance, inspect the machine for any

signs of damage, such as missing or damaged components, cracked welds, etc.

12. Check the track assemblies to make sure that:

• The tracks are in good condition and are not showing any signs of wear.

• Track tension is properly set.

• Track drive motors are not leaking oil or hydraulic uid.

13. Grease pivot shafts with proper type of grease. There are 14 grease points on

this machine, see Figure 3–7 on page 3-7.

14. Inspect the Track Widening Stop Bolts, one for each track assembly, (Item 1,

Figure 3–8) for:

• Signs of wear or damage and make sure that the bolt is not loose.

• Check the widening bolt lock nut (Item 2, Figure 3–8) to make sure that it is tight

against the mounting block (Item 3, Figure 3–8).

NOTE: The lock nut, when it is fully tightened, secures the track widening stop bolt

to the mounting block.

• The track extension system has been designed to have a slight gap between the track

frame and the stop bolt head when the tracks are fully extended. If this gap is not noted,

the track widening stop bolts need to be adjusted. Refer to Section 4 for the adjustment

instructions.

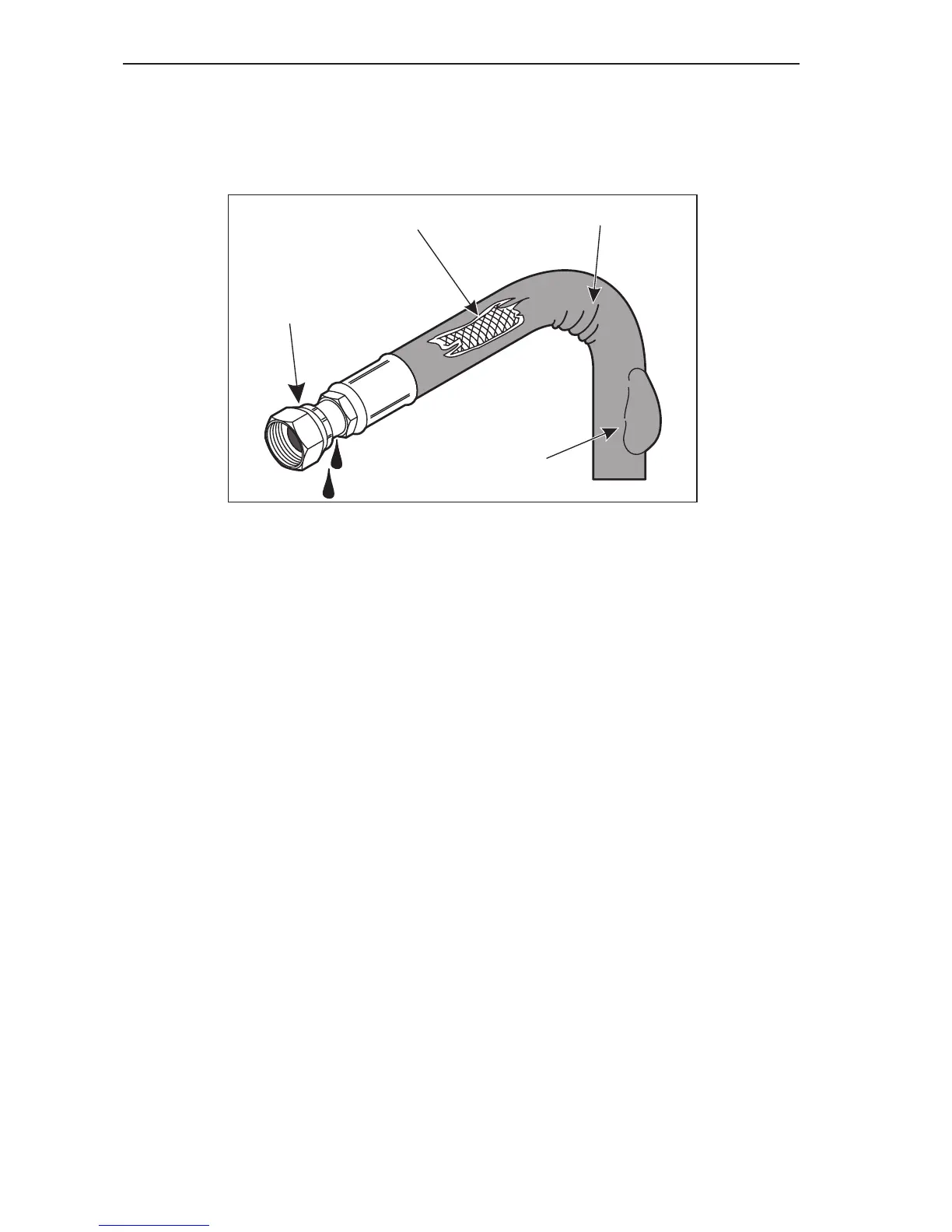

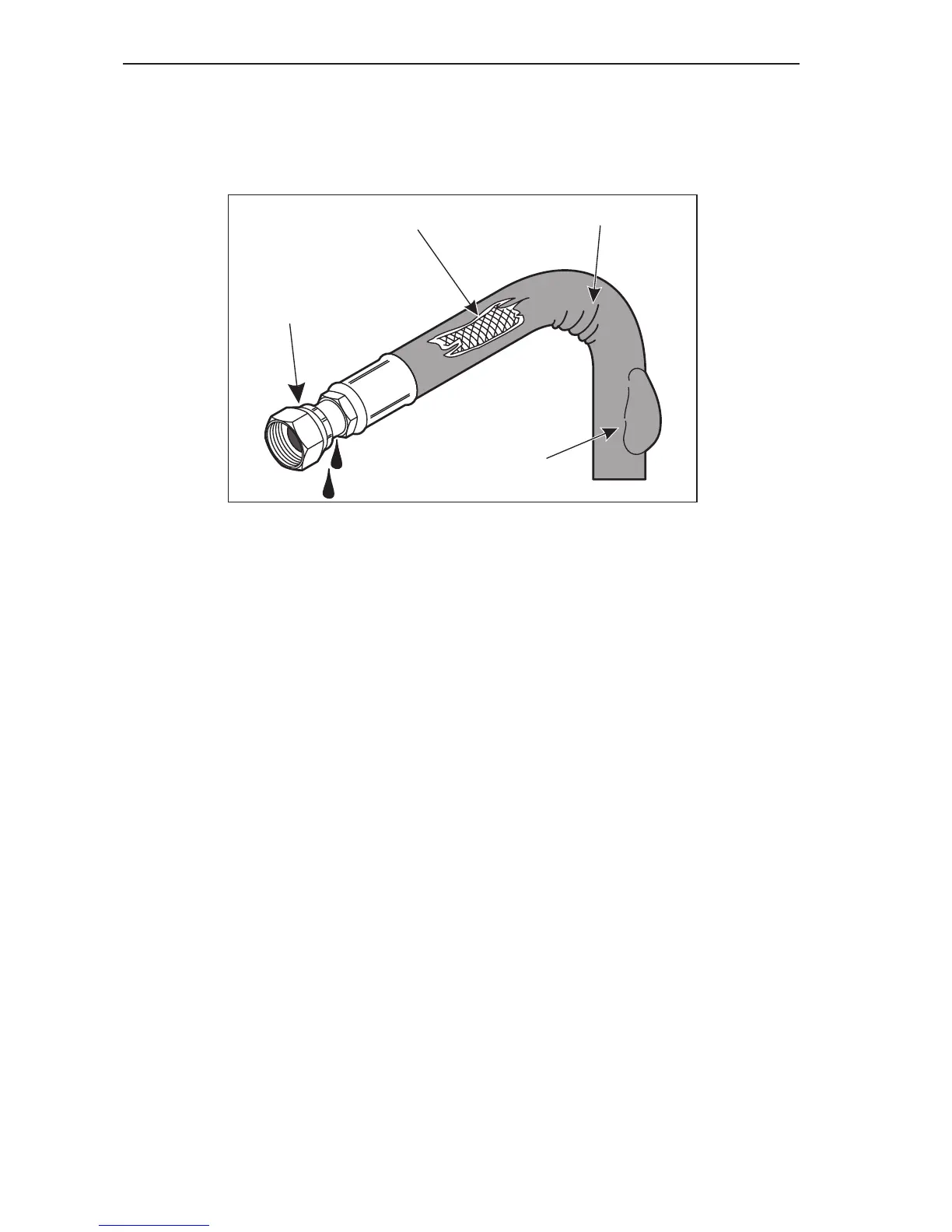

1. End ttings damaged or leaking.

2. Outer covering chafed or cut, and reinforcing wire is

exposed.

3. Hose shows signs of kinking or crushing.

4. Outer covering ballooning.

• Visually inspect all of the hydraulic hoses, lines, and ttings for signs of damage, wear

or leaking.

• If any signs of damage are visible, do not operate the machine until repairs have been

made.

• Some examples of common hydraulic hose damage are shown in Figure 3–6.

Figure 3-6 Hydraulic Hose Damage

1

3

4

2

Loading...

Loading...