Routine Service and Maintenance

4.26

Track and Tension System Installation

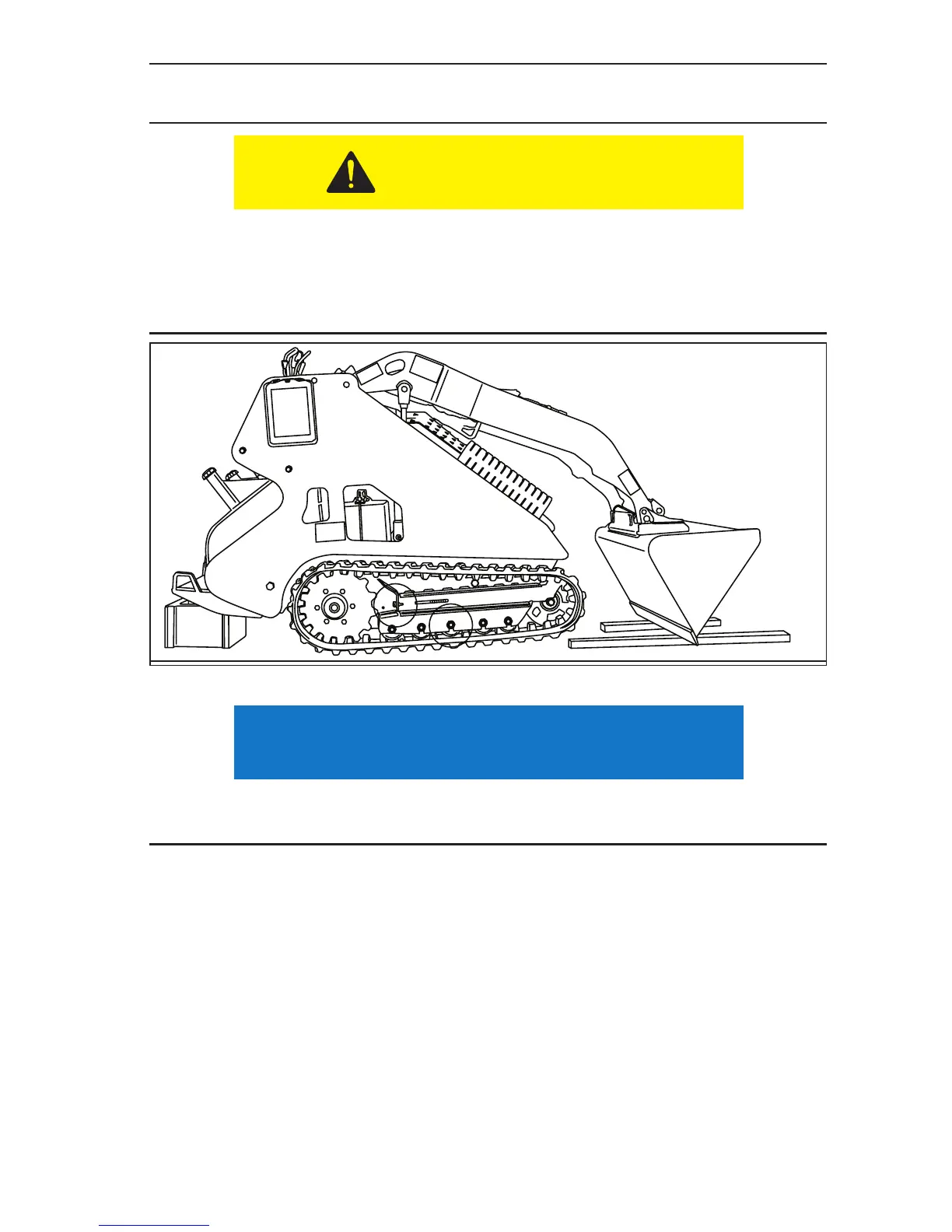

1. Securely elevate the machine. See Figure 4–26 and Track Tensioning instructions.

• Make sure that the machine has been securely elevated and that there is no

danger of it tipping before beginning this procedure.

• To fully stabilize the machine, it may be necessary to insert an additional support

at the front of the machine, under the hydraulic tank. When this support has

been installed, raise the boom.

Figure 4-26 Machine Elevation

If any of the track tensioning components have come out of the track tension assembly when

the track came off of the machine, proceed to Step 2. If not, skip to Step 7.

2. Fully extend the track assemblies.

3. Shut off the engine.

4. Install tension bolt and thrust washer (Item 1, Figure 4–27) into track frame.

NOTE: Make sure that the thrust plate is rotated as far backwards as possible on

the tension bolt, releasing all track tension.

5. Install tension spring (Item 2, Figure 4–27) into track frame.

6. Install idler wheel (Item 3, Figure 4–27) assembly into track frame.

NOTE:

• Make sure that the idler wheel assembly is installed so that the axle bolt head is visible

and that the lower edge of the idler wheel aligns with the lower edge of the idler rollers.

• Make sure to slide the tension system components as far back into the track frame as

possible.

CAUTION

NOTICE

Loading...

Loading...