SERIES 70 ELECTRIC ACTUATOR

Installation, Operation, and Maintenance Manual

19 of 48

© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM

The Information contained herein shall not be copied, transferred, conveyed, or displayed in any manner

that would violate its proprietary nature without the express written permission of Bray International, Inc.

ACTUATION

Manual Operation

The manual override operates similar to a watch adjusting knob To engage the

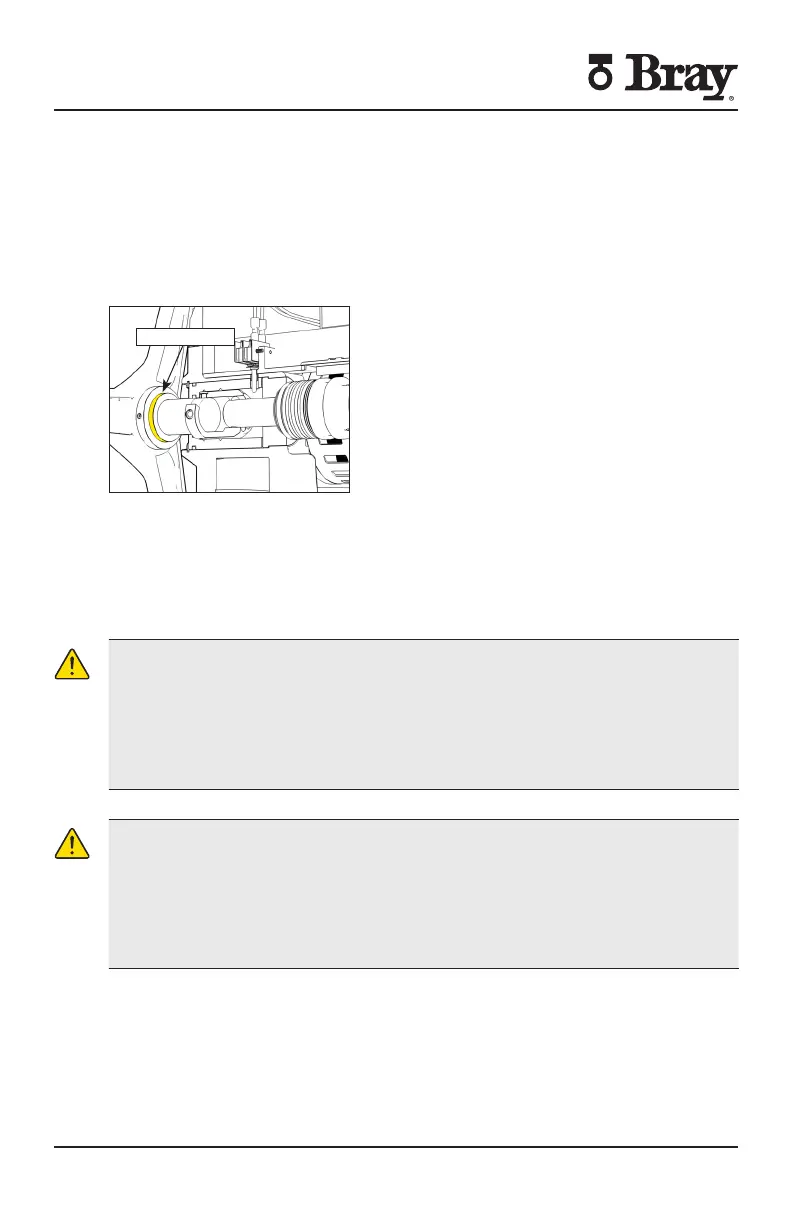

manual override simply pull the handwheel to its outermost position A yellow stripe

is revealed to visually indicate manual override engagement as shown in Figure

The two handwheel positions engaged and disengaged are held in place with the

use of spring plungers The handwheel remains in position until physically moved

Yellow Stripe

Figure - Handwheel is engaged revealing the yellow stripe

Once the manual override is engaged rotating the handwheel in the clockwise

direction will rotate the output shaft in the clockwise (close) direction and vice-

versa

To disengage the manual override the handwheel needs to be pushed towards the

actuator until the ‘yellow stripe’ is hidden

CAUTION

A label on the handwheel hub warns users not to exceed a specific ‘rim pull’ force

for each size of actuator

If the ‘rim pull’ force is exceeded the roll pin securing the handwheel onto the

manual override shaft is designed to shear thus preventing serious internal gearing

damage

Remote Operation

CAUTION

1. Verify that the main electric power supplied to the actuator is in compliance with

the specifications on the actuator label.

2. Engaging the handwheel before or during the application of a supply voltage

will prevent the actuator motor from operating.

3. If torque switches are installed in the actuator, an over-torque condition will

prevent the actuator motor from operating in the direction of fault.

Loading...

Loading...