SERIES 70 ELECTRIC ACTUATOR

Installation, Operation, and Maintenance Manual

44 of 48

© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM

The Information contained herein shall not be copied, transferred, conveyed, or displayed in any manner

that would violate its proprietary nature without the express written permission of Bray International, Inc.

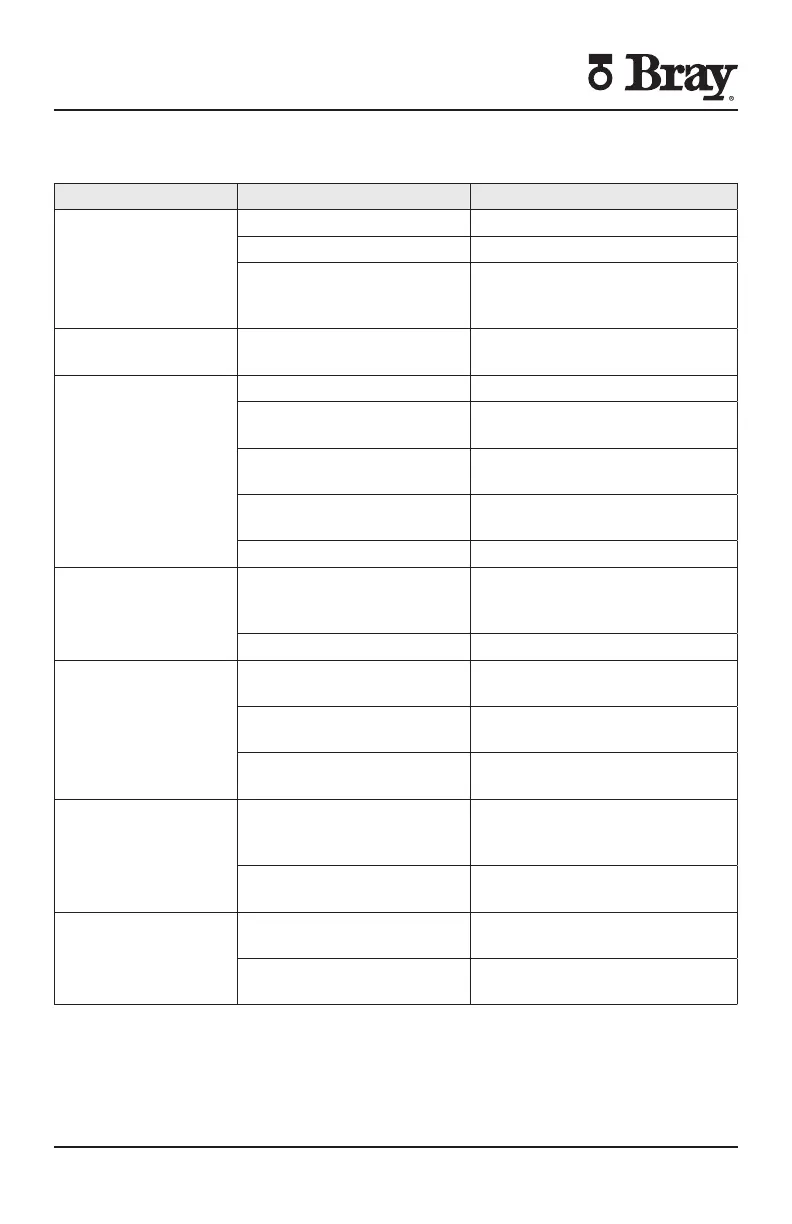

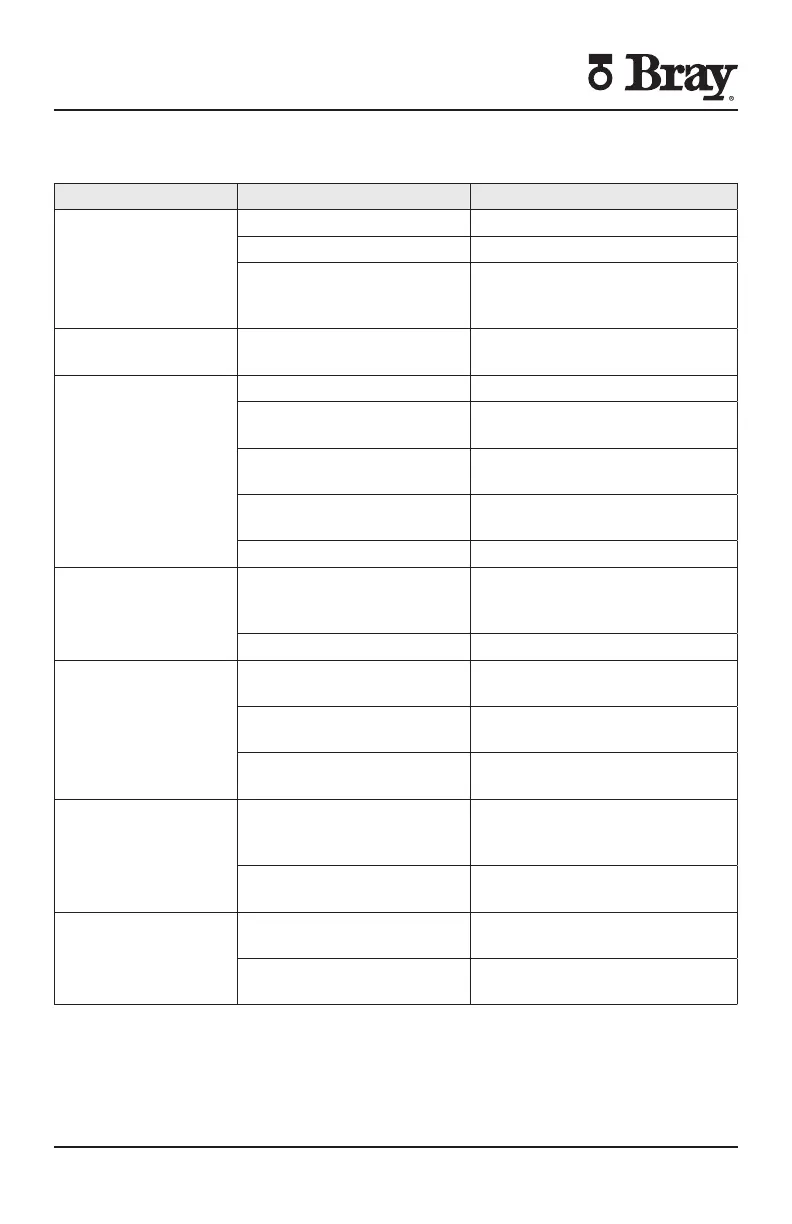

APPENDIX B - ACTUATOR TROUBLESHOOTING CHART

Problem Possible Cause Solutions

Actuator does not

operate

Override is engaged Push handwheel in all the way

Wiring is incorrect Check wiring and power supply

Actuator motor has reached

its thermal shutdown

temperature

Allow time to cool

Actuator operates in

reverse directions

Field wiring is reversed Rewire field wiring

Actuator does not fully

close valve (or open

valve)

Limit switches are depressed Readjust travel limit switches

Mechanical travel stop is

stopping actuator

Adjust mechanical travel stops

Valve torque requirement is

higher than actuator output

Manually override out of seat try

angle seating or larger actuator

Optional torque switches are

activating

Valve torque exceeds actuator

torque rating - consult factory

Voltage power supply is low Check power source

Engaging override

handwheel does not

shut o motor

Override pin is corroded or

damaged

Clean and check for smooth

operation of the override switch

pin

Override switch is damaged Replace switch

Disengaging override

hand-wheel does not

restart motor

Not completely disengaged

Push handwheel in as far as

possible (no yellow showing)

Override pin is damaged or

and does not activate switch

Replace override pin

Incorrect wiring of override

switch

Check wiring

Motor runs but worm

and gear segment do

not

Worm gear segment is not

meshing with worm

Remove switch plate and inspect

adjust travel stops to prevent gear

disengaging

PinKey on WormMotor

drive gear sheared

Replace PinKey on drive gear

Corrosion inside unit

Condensation forming

Test heater wiring should have

constant power

Water leaking in

Check all seals and possible water

entry through conduit

Loading...

Loading...