SERIES 70 ELECTRIC ACTUATOR

Installation, Operation, and Maintenance Manual

23 of 48

© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM

The Information contained herein shall not be copied, transferred, conveyed, or displayed in any manner

that would violate its proprietary nature without the express written permission of Bray International, Inc.

Wiring the Actuator

WARNING

Turn o all power and lockouttag out service panel before installing or modifying

any electrical wiring

1. Take the actuator cover o. The cover should be kept on hand for reference.

2. Wire the actuator as per the wiring diagram attached to the inside of the

actuator cover.

NOTICE

1. Power and control wiring should use separate conduit entries.

2. A minimum of 18 AWG wire is recommended for all field wiring.

3. Terminals directly mounted on the actuator switch plate accept wire sizes

ranging from 14 to 22 AWG.

4. Terminals of internally mounted electronics modules accept wire sizes ranging

from 14 to 24 AWG.

5. The conduit connections must be properly sealed to maintain the weatherproof

integrity of the actuator enclosure.

Setting Travel Limit Switches

NOTICE

If the unit came assembled to a valve the switches have been factory-set and DO

NOT need adjustment

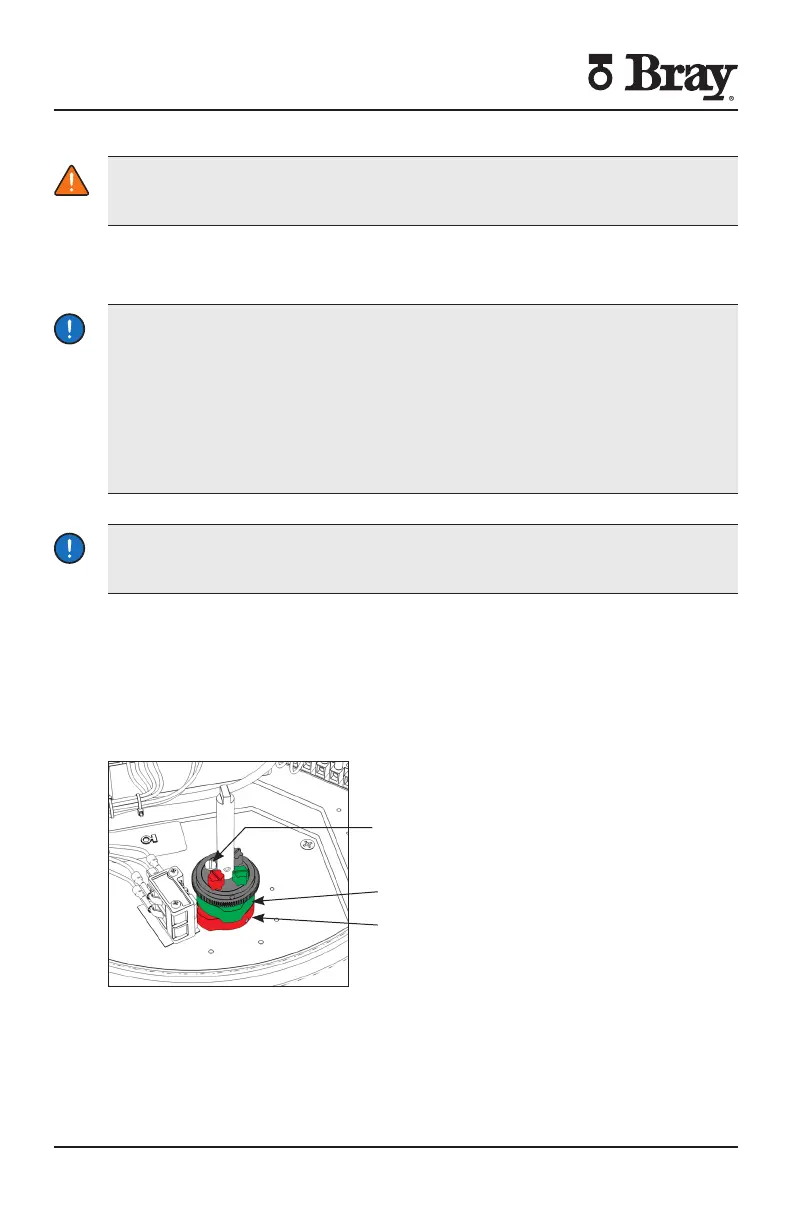

Bray uses its patented cam design along with two SPDT mechanical switches to set

the ‘Open’ and ‘Closed’ position of the valve The green cam actuates the ‘open’

switch when the actuator reaches the ‘open’ position Similarly the red cam actuates

the ‘closed’ switch when the actuator reaches the ‘closed’ position

Standard factory setting of the travel limit switches allows travel between open

and close positions Cams for each switch are adjustable for applications where less

than -degree travel is desired between the open and closed positions

Cam Locking Screw

Figure Two SPDT Travel Limit Switches

Follow the steps below to adjust the travel limit cams

NOTE For Actuator Size ignore steps and

Green - Open

Red - Closed

Loading...

Loading...