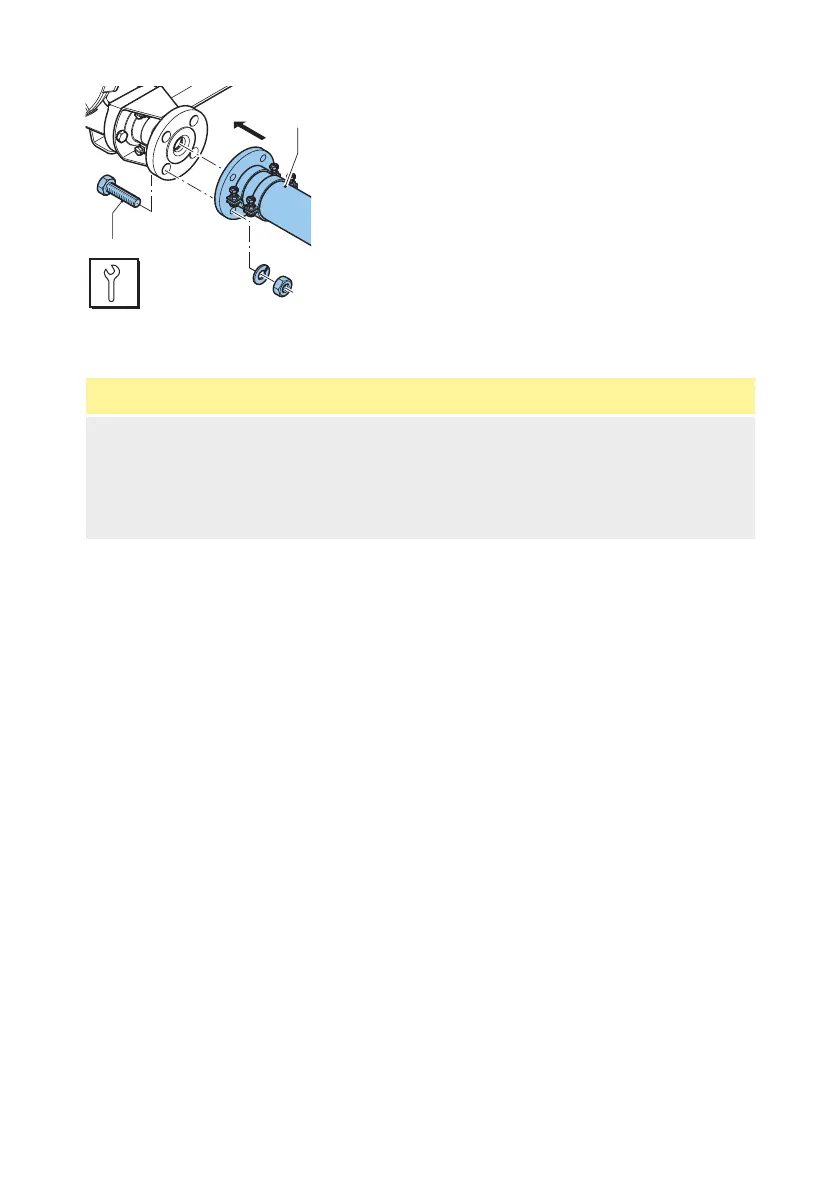

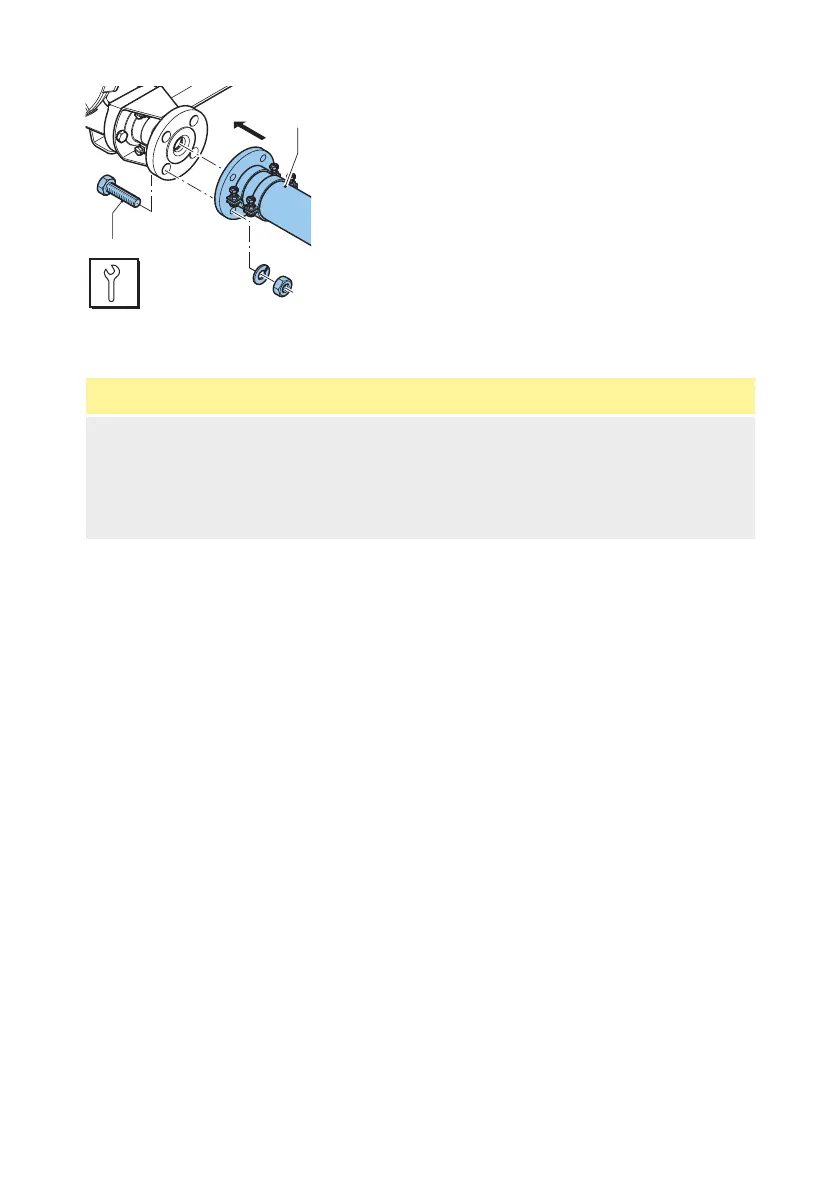

13. Connect the suction and discharge lines (B).

14. Position the retaining bolts (A) and tighten them to the specified torque.

See also

Refer to "Torque figures" on page 85

Refer to "Changing lubricant" on page 45

Refer to "Changing lubricant" on page 45

Refer to "Tightening the hose clamps" below

Tightening the hose clamps

How to tighten hose clamps in combination with steel inserts

As a first step, apply the initial setup torque value as advised in the table below. In some cases, an

adjustment to the specified torque values is required. This can be due to excessive friction between

the thread of the tightening bolt and the clamp. The actual clamping force needed can deviate from

the clamping force derived from the specified torque values. To minimize this risk, it is advised to

grease the clamping bolts.

If the specified torque values lead to a leaking hose connection, it is advised to carefully increase the

bolt torque until a sealed situation is obtained. Here the absolute torque value is of less importance.

The maximum allowable amount of clamping is indicated in the table below as a minimum allowable

outer diameter of the clamp (OD). A suitable indication is the difference between hose outer diameter

and clamp outer diameter ΔD.

54 m-bredel-25-32-en-05

Loading...

Loading...