Note: Contact your Bredel representative for advice about the chemical and temperature resistance

of the hoses.

The Bredel hoses are carefully manufactured and quality checked to achieve minimum tolerances in

wall thickness.

It is very important to guarantee the correct compression of the hose, because:

• When the compression is too high, it creates an excessive load on the pump and hose, which

may reduce the life of the hose and bearings.

• When the compression is too low, it cuts capacity and causes backflow. Backflow reduces the

life of the hose.

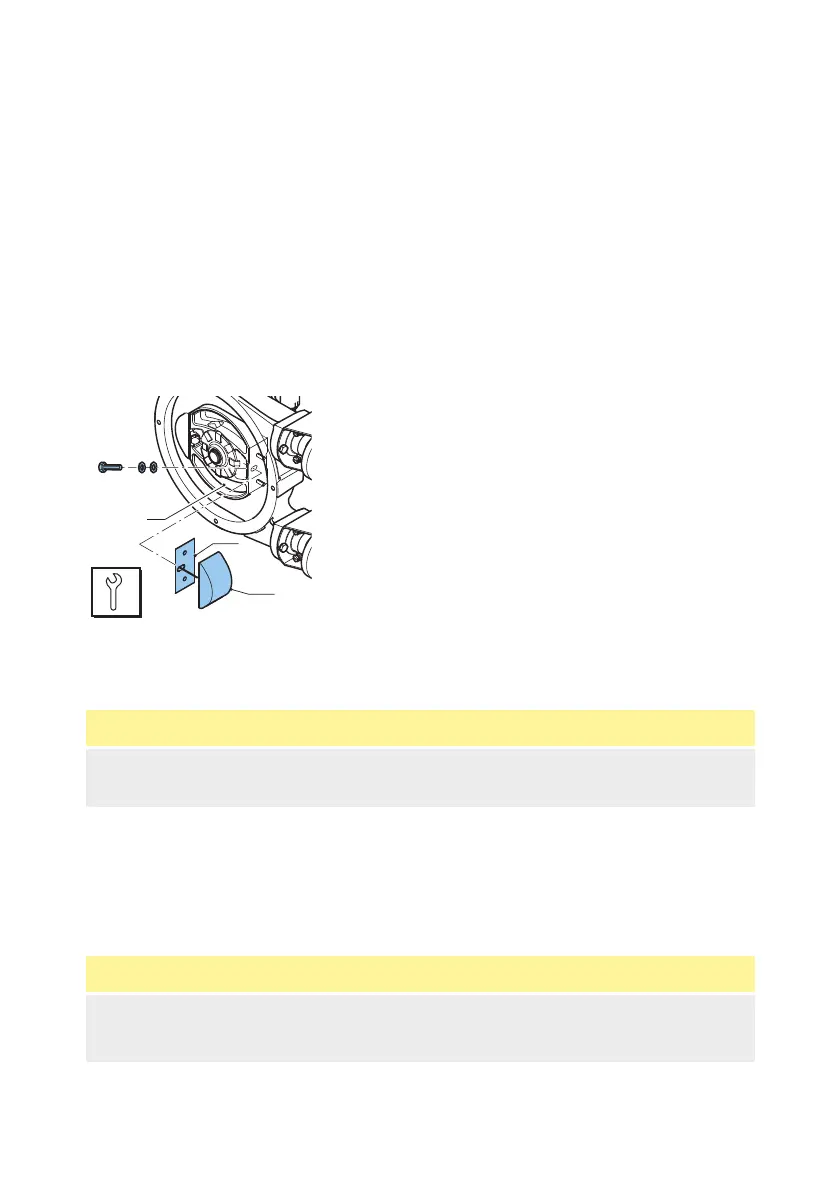

Hose compression force adjustment

In order to achieve optimal life of the hose, the compression force of the pump hose can be adjusted

by placing a number of shims under the pressing shoes. The shims (A) are fitted between the rotor (B)

and the pressing shoe (C). The number of shims will vary for each counterpressure situation.

See also

Refer to "Adjust the compression force (shimming)" on page 66 for how to select and install the

shims.

Lubrication and cooling

The pumphead is filled with Bredel Genuine Hose Lubricant. This lubricant lubricates the pressing

shoes and dissipates the generated heat via the pump and the cover.

The lubricant is food grade. The user is responsible to ensure the chemical compatibility of the

lubricant with the fluid to be pumped.

See also

Refer to "Lubricant table pump" on page 83 for the required quantity and NSF registration.

Refer to "Hose failure" on page 38 for the consequences of a hose failure.

m-bredel-25-32-en-05 25

Loading...

Loading...