Note: Specifications only valid for genuine Bredel hoses.

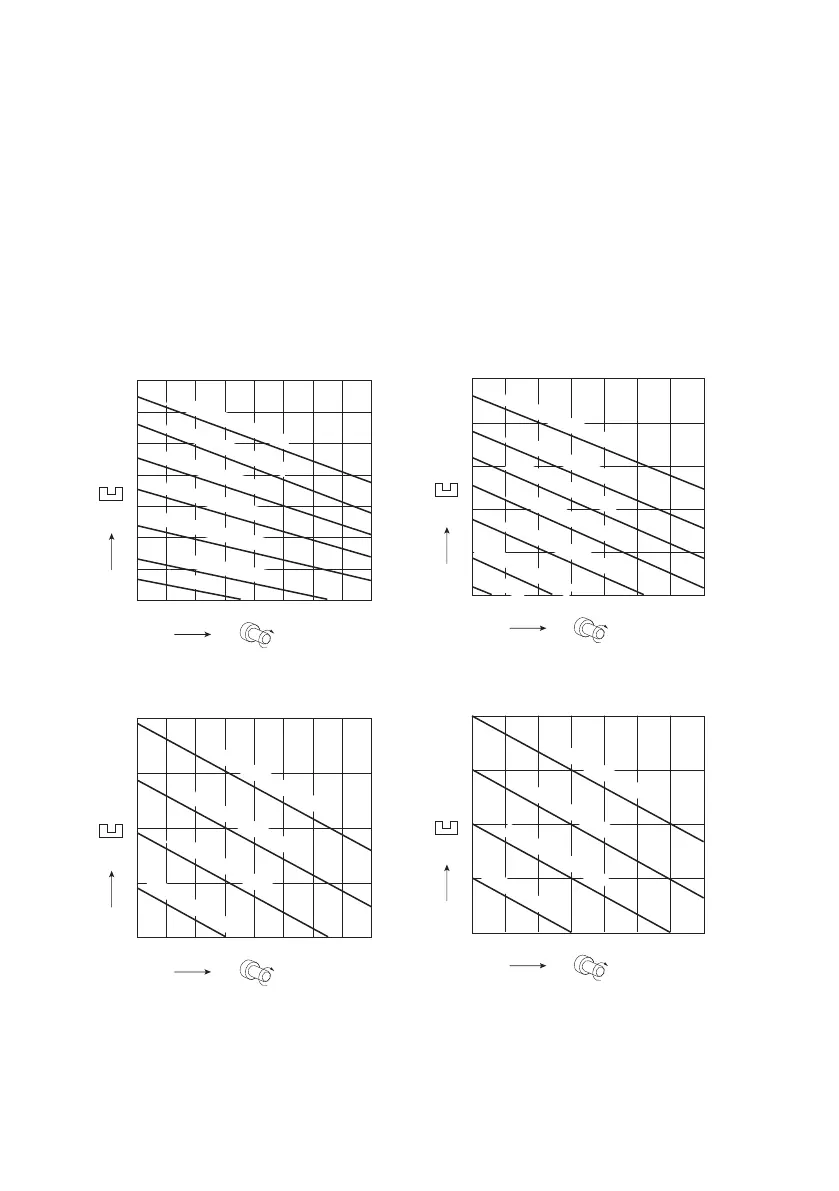

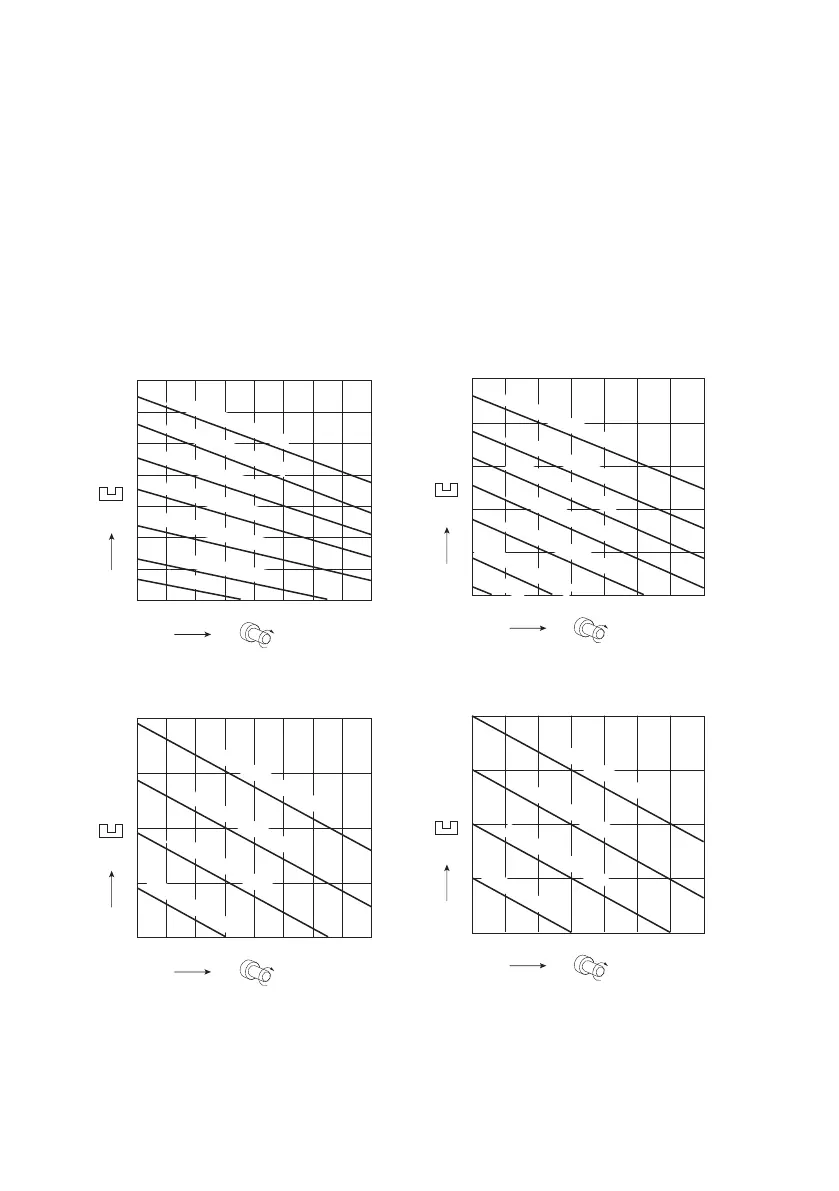

1. Find the pump speed in [rpm] on the horizontal axis.

2. Go straight up and meet the proper discharge-pressure line.

3. At that point, go straight to the left and read the number of shims Yon the vertical axis.

4. Always round up the number of shims.

• When the product temperatures are above 60 °C always use one shim less than indicated in

the diagrams.

• Each diagram gives the number of shims per pressing shoe.

• Shim both pressing shoes identically.

6

7

0

0

120 140 16010080604020

Bredel 25 - NR Metering hose

5

4

3

2

1

X

Y

1600kPa - 16bar - 232psi

1250kPa - 12.5bar - 181psi

1000kPa - 10bar - 145psi

750kPa - 7.5bar - 109psi

500kPa - 5bar - 72.5psi

250kPa - 2.5bar - 36psi

0kPa - 0bar

5

4

3

2

1

0

0 20 40 60 80 100 120 140

Bredel 32 - NR Metering hose

X

Y

1600kPa - 16bar - 232psi

1250kPa - 12.5bar - 181psi

1000kPa - 10bar - 145psi

750kPa - 7.5bar - 109psi

500kPa - 5bar - 72.5psi

250kPa - 2.5bar - 36psi

0kPa - 0bar

X = Pump speed Y = Number of shims per shoe

6

0

120 140 16010080604020

Bredel 25 NR - Transfer Hose

5

4

3

2

X

Y

1200 kPa - 12 bar - 174 PSI

800 kPa - 8 bar - 116 PSI

400 kPa - 4 bar - 58 PSI

0 kPa - 0 bar - 0 PSI

6

5

4

3

2

0 20 40 60 80 100 120 140

Bredel 32 NR - Transfer Hose

X

Y

1200 kPa - 12 bar - 174 PSI

800 kPa - 8 bar - 116 PSI

400 kPa - 4 bar - 58 PSI

0 kPa - 0 bar - 0 PSI

X = Pump speed Y = Number of shims per shoe

86 m-bredel-25-32-en-05

Loading...

Loading...