3-18

START-UP PROCEDURE -- PISTON PUMP

When initially starting a new or rebuilt transmission pump, it is extremely important that

the start-up procedure be followed. It prevents damaging the unit that might occur if the

system is not properly purged and charged with oil before start-up.

1. After the propulsion components have been properly installed, fill pump housing at

least half full with new hydraulic fluid, as specified on page 3-21. Connect all

hydraulic lines and check to be sure they are tight.

2. Check the wiring connections to the pump control.

3. Fill the reservoir with approved hydraulic fluid that is new and clean. Install a 0 to 300

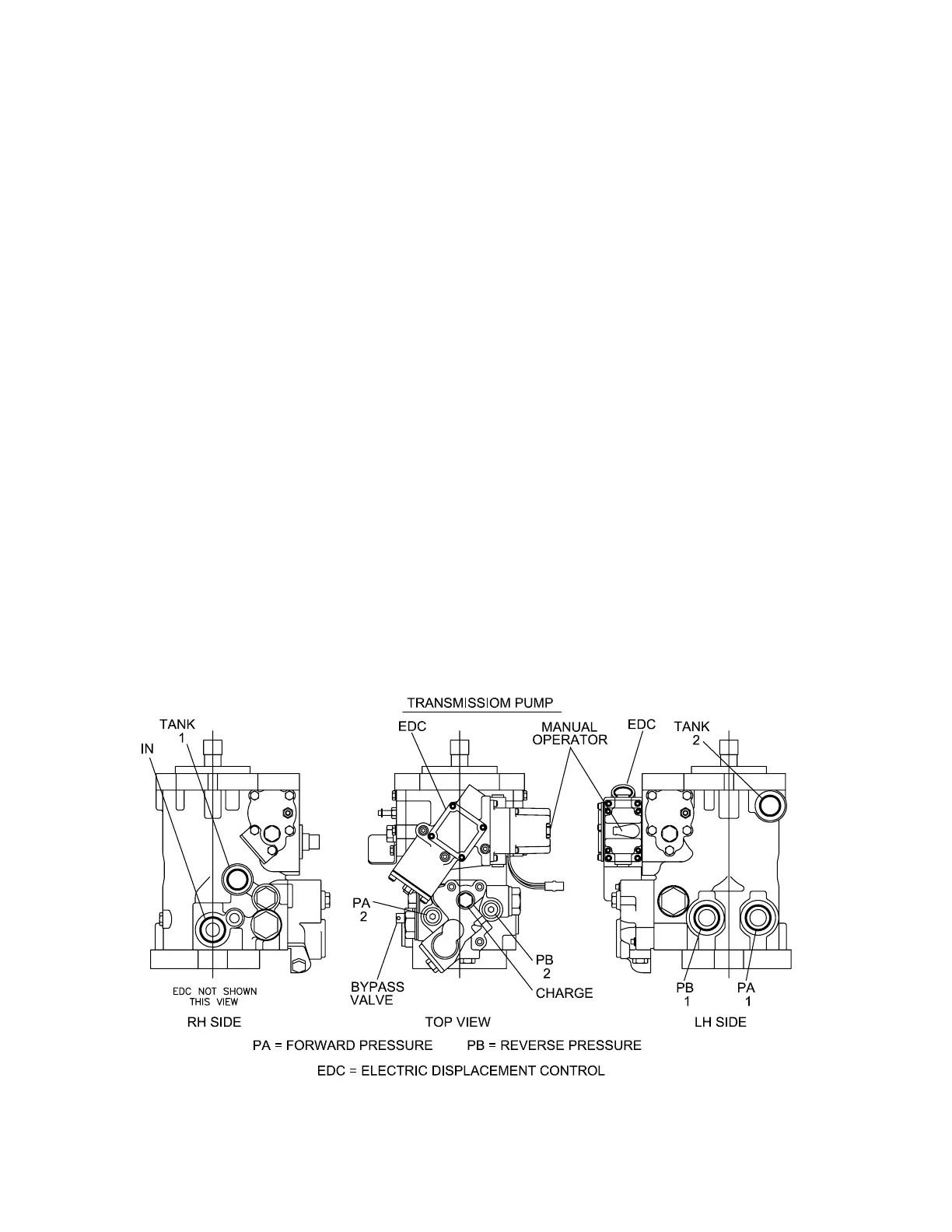

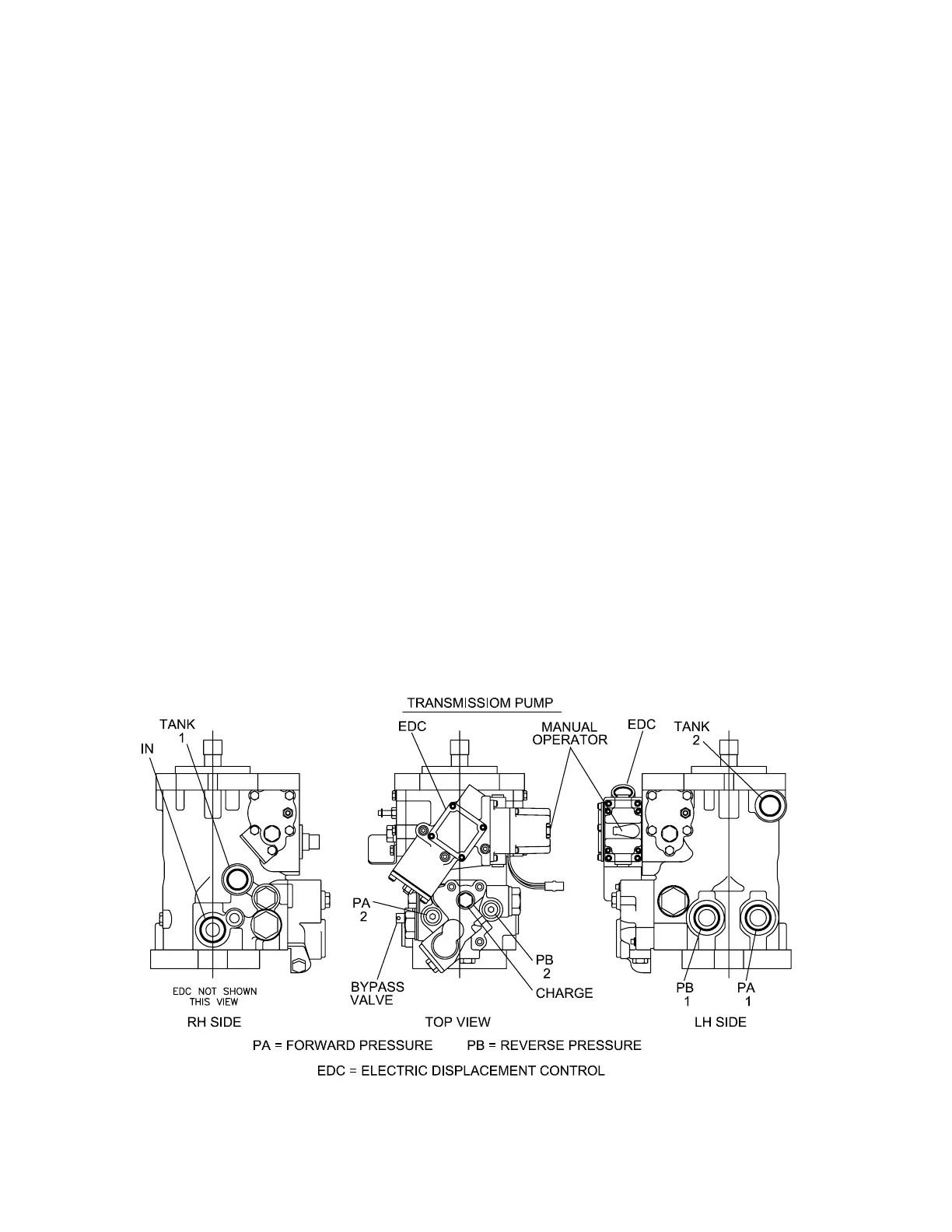

PSI (0 to 20 bar) gauge in the charge pressure port. The port is the highest port on

top of the pump and has a #6 elbow with a ¼” hose that connects with the brake

release valve. This may be disconnected, or a tee may be inserted. See figure

below.

4. Gasoline or L.P. Engines: Remove the coil wire and turn the engine over for 15

seconds. Diesel Engines: Shut off the fuel flow to the injectors and turn the engine

over for 15 seconds. This procedure enables the charge pump to pick up the oil

before start-up.

5. Replace the coil wire or return the fuel flow to the injectors. Keep the transmission

control switch in the neutral position, start the engine, and run it at a low idle. The

charge pump should immediately pick up oil and fill the system. If there is no

indication of fill in 30 seconds (gauge in charge pressure port of the pump should

register about 220 PSI (15 bar)), stop engine and determine the cause.

Loading...

Loading...