3-19

6. After the system shows signs of filling, run it in neutral and low idle for 5 minutes.

Then extend the outriggers so that drive wheels can spin freely. Reconnect the brake

release valve if disconnected in step 3. Place the control switch in the FORWARD

position and slowly push the accelerator until the wheels turn slowly. Run for 5

minutes and repeat in reverse direction. Then increase to full throttle for one minute

in each direction.

7. Check fluid level in the reservoir and fill to the proper level. Check all line

connections for leaks and tighten if necessary.

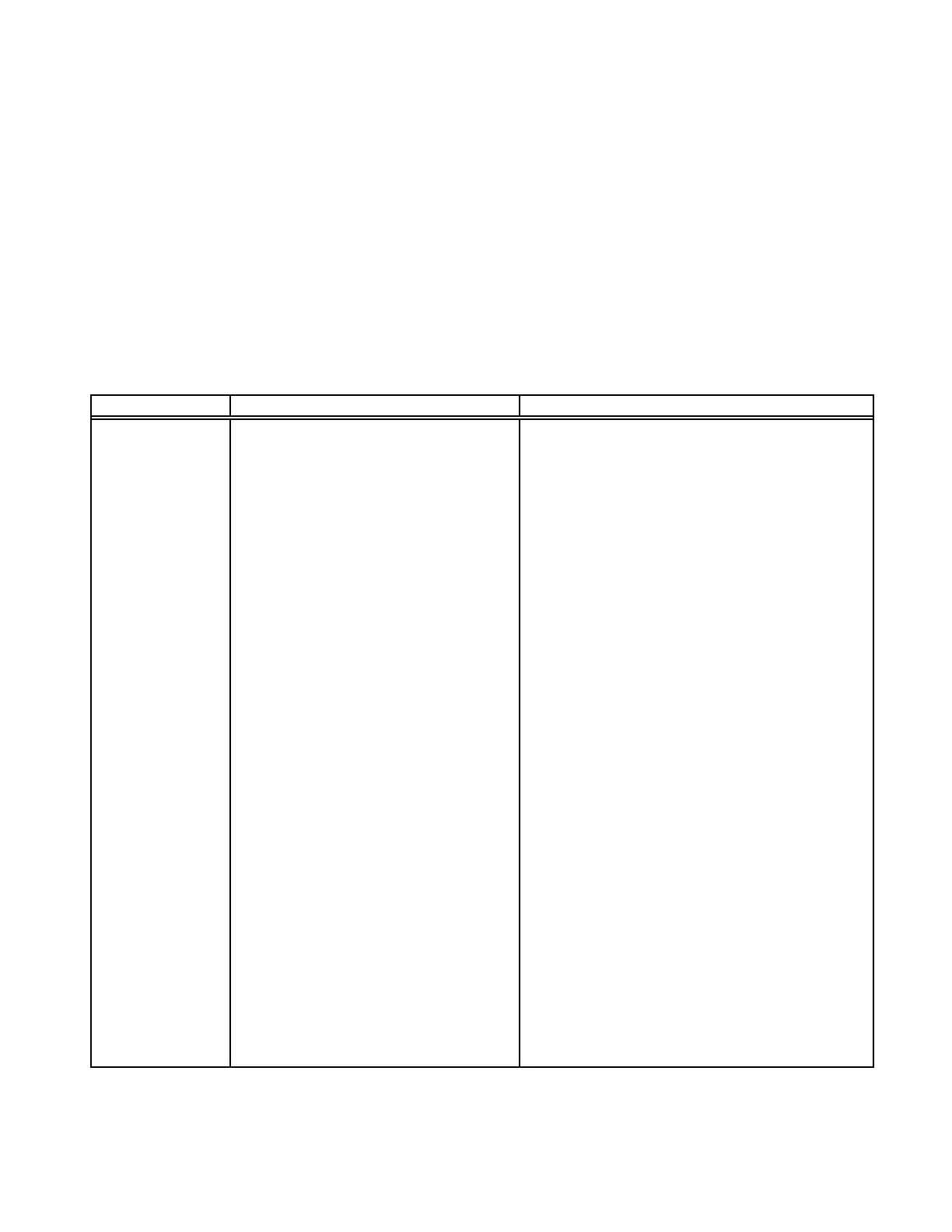

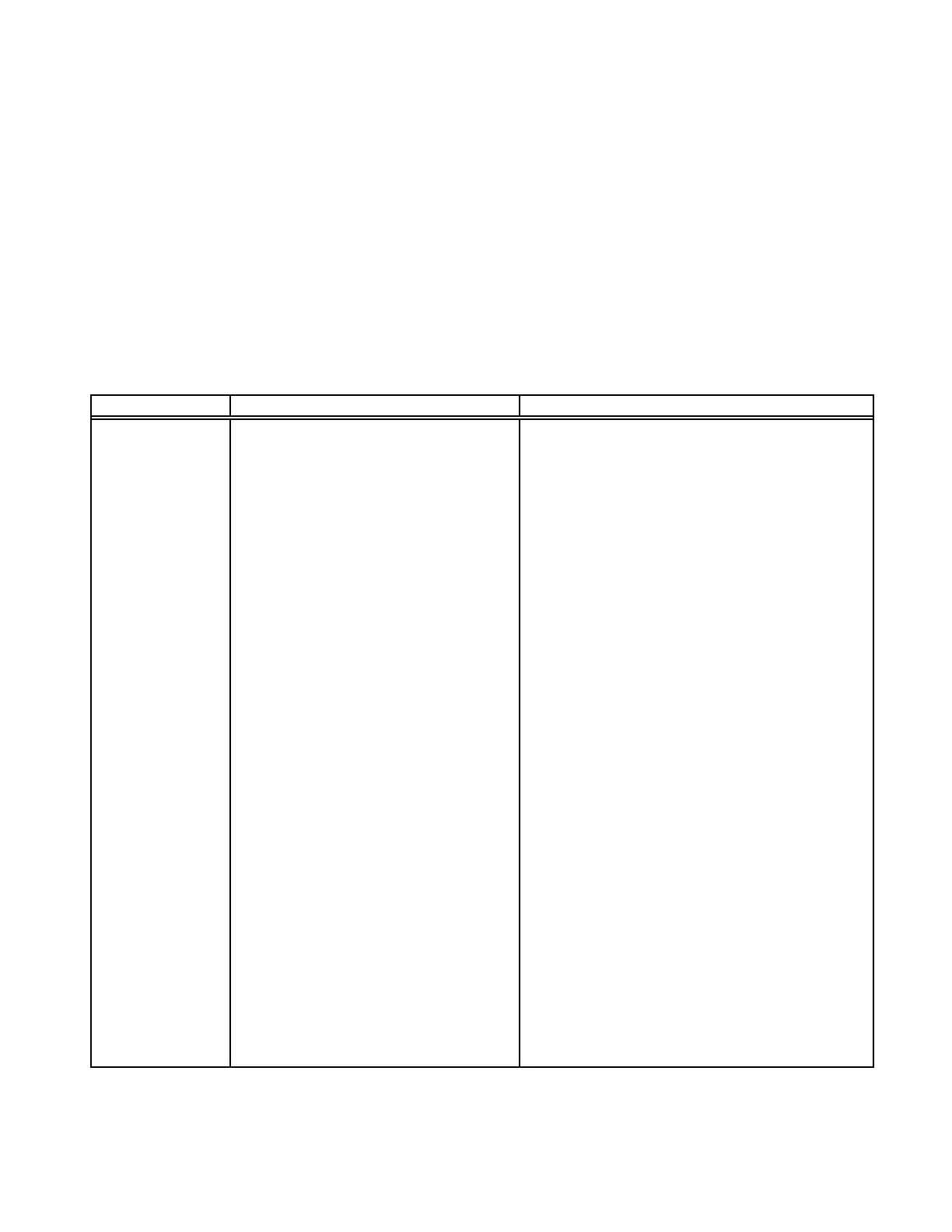

IC-40 PISTON PUMP TROUBLESHOOTING

TROUBLE CAUSES REMEDIES

1. System will A. Brake switch tripped Release brake switch.

not operate B. Oil supply low Check oil level, fill.

in either C. Oil filter clogged Replace filter element.

direction. D. Oil too heavy Use proper viscosity oil.

E. Bypass valve open Close bypass valve.

F. Bad electrical connection Check all related connections.

G. Circuit breaker open Fix short, overload or breaker.

H. Defective switch Replace switch.

I. Defective RPM sensor Fix or replace sensor.

J. Defective controller circuit Replace controller circuit.

K. Defective pump solenoid Replace pump solenoid.

L. Defective brake release solenoid Fix or replace solenoid or wiring.

M. Low charge pressure--below 200 PSI See below: N, O, P,Q.

N. Charge pump relief valve damaged Remove relief valve parts. Examine parts and seat.

Replace damaged parts.

O. Damaged internal charge check valve Disassemble and determine if check valve is faulty.

P. Charge pump key sheared Inspect charge pump for damage & replace key.

Q. Charge pump worn or scored or damaged Remove parts and examine. Replace defective parts. If

severe scoring is indicated, remove complete pump unit,

disassemble and inspect for damage.*

R. Drive coupling broken Inspect coupling for sheared spline.

S.

Forward or reverse relief valve stuck

open

Remove relief valve. Clean or replace.

2. Pump is noisy. A. Air in system Fill oil reservoir. Check and fix suction line leaks.

B. Clogged filter Replace filter element.

C. Internal pump or motor wear or damage Disassemble, inspect and repair.*

3. Sluggish A. Air in system See Steps 1-B, 1-D, 2-A.

response to B. Low charge pressure See Step 1-L.

acceleration C. Loose bypass valve Close bypass valve.

or deceleration D. Internal pump or motor wear or damage Disassemble, inspect and repair.*

E. Relief valve dirty or damaged Remove, clean or replace.

*

Pump should be disassembled only by experienced hydraulic pump repair personnel,

preferably at a Sauer Danfoss Service Center.

Loading...

Loading...